Novel aluminium piston wearable collar and method for manufacturing piston

A manufacturing method and a technology for inserting rings, which are applied in the directions of pistons, engine components, machines/engines, etc., can solve the problem of coarse metallographic structure of wear-resistant insert rings and throat guard rings of combustion chambers, easy to produce looseness and shrinkage, and increase the number of pistons. Weight and other issues, to achieve the effect of small product weight, good cooling effect and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

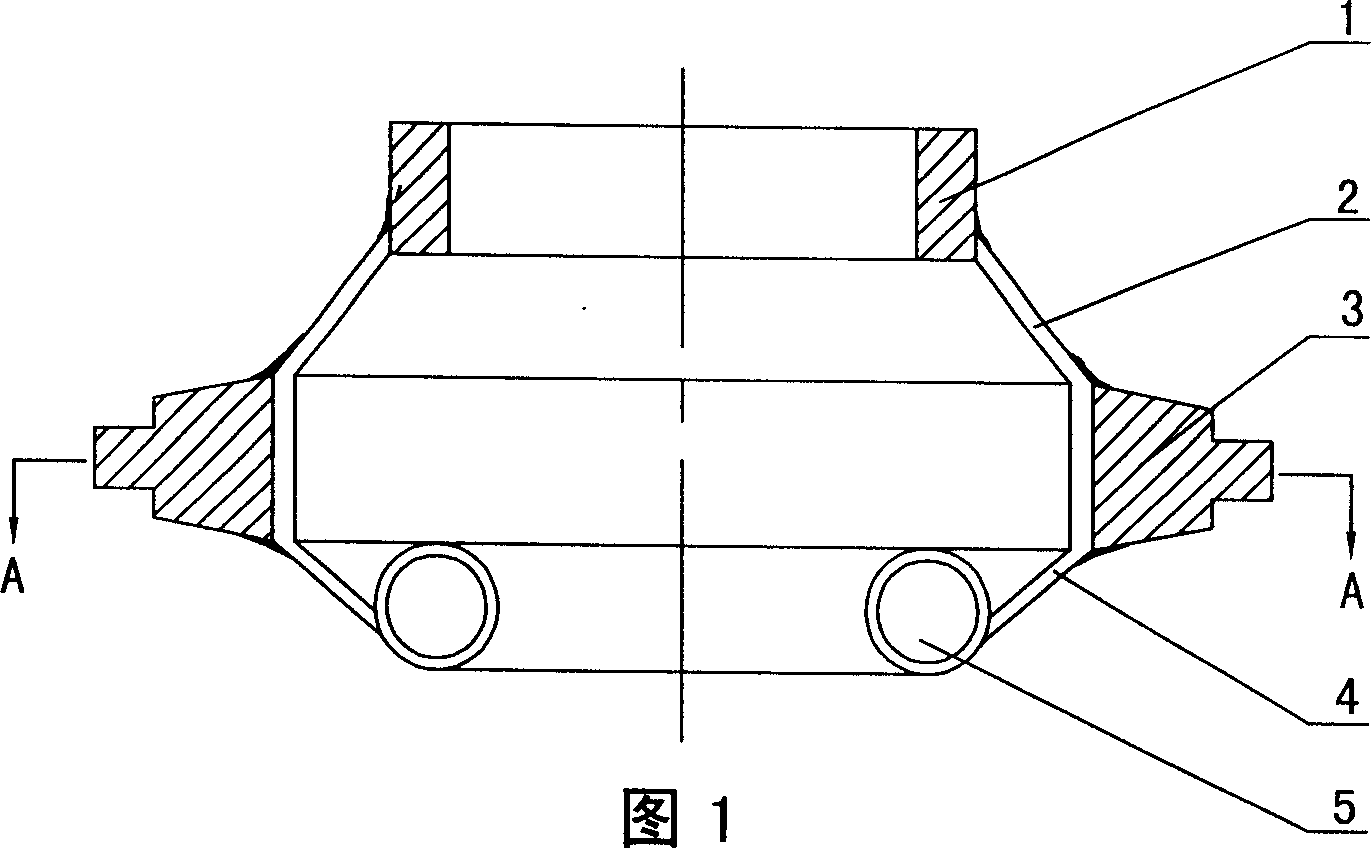

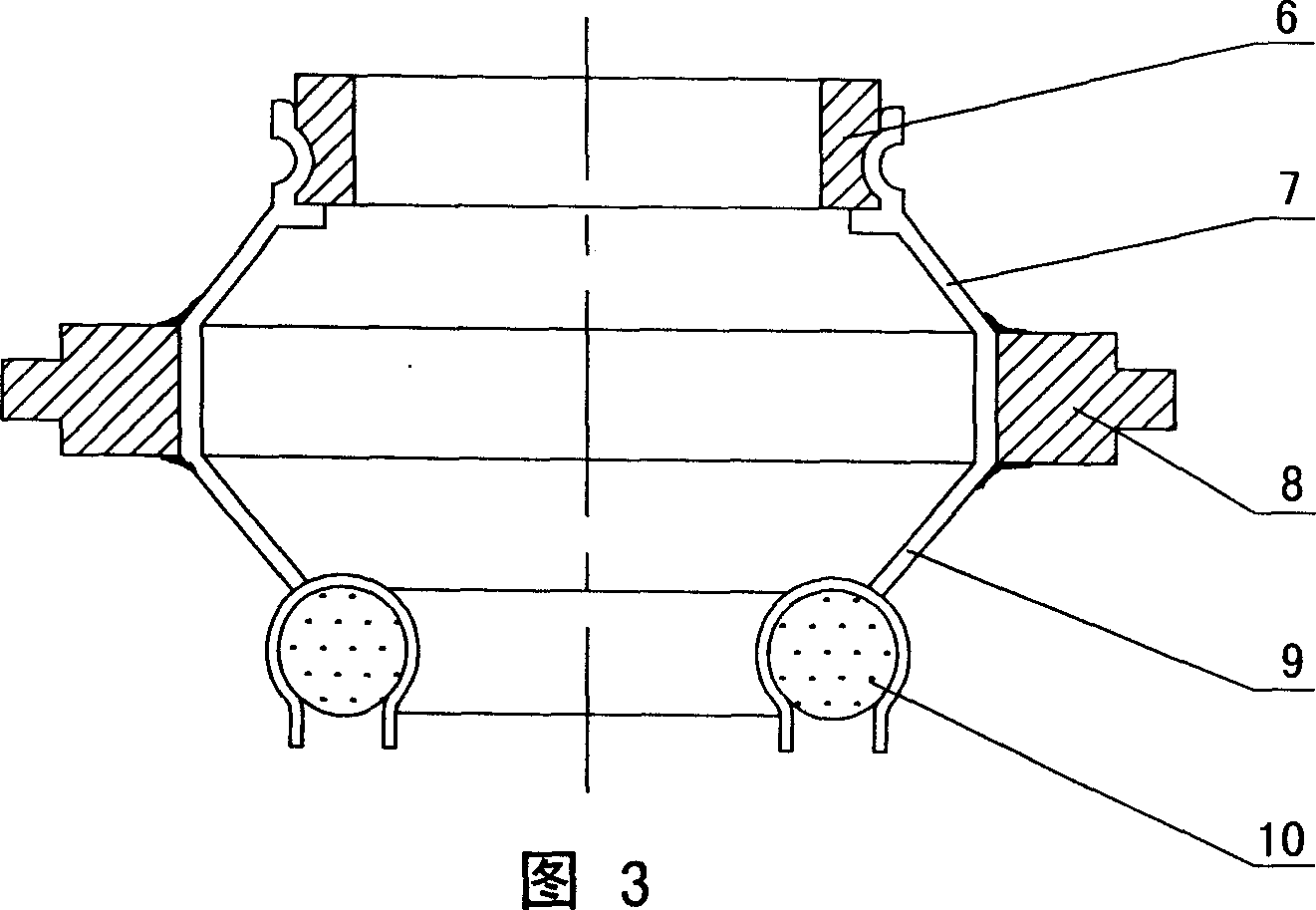

[0020] As shown in Figure 1, the new aluminum piston wear-resistant insert ring of the present invention includes a wear-resistant insert ring 3 and an internal cooling channel 5, and the wear-resistant insert ring 3 with a boss passes through the internal cooling channel 5 of the metal hollow ring. The bracket 4 is welded, and the bracket 4 is supported in the wear-resistant insert ring 3; the wear-resistant insert ring 3 is welded with the combustion chamber throat retainer 1 through the support 2.

[0021] The internal cooling channel 5 and the throat retainer 1 are fixedly connected to the wear-resistant insert ring 3 through the integrated connecting bracket 4, 2. When making the piston, the internal cooling channel 5 and the throat retainer 1 are together with the wear-resistant insert ring 3 Cast into the piston body.

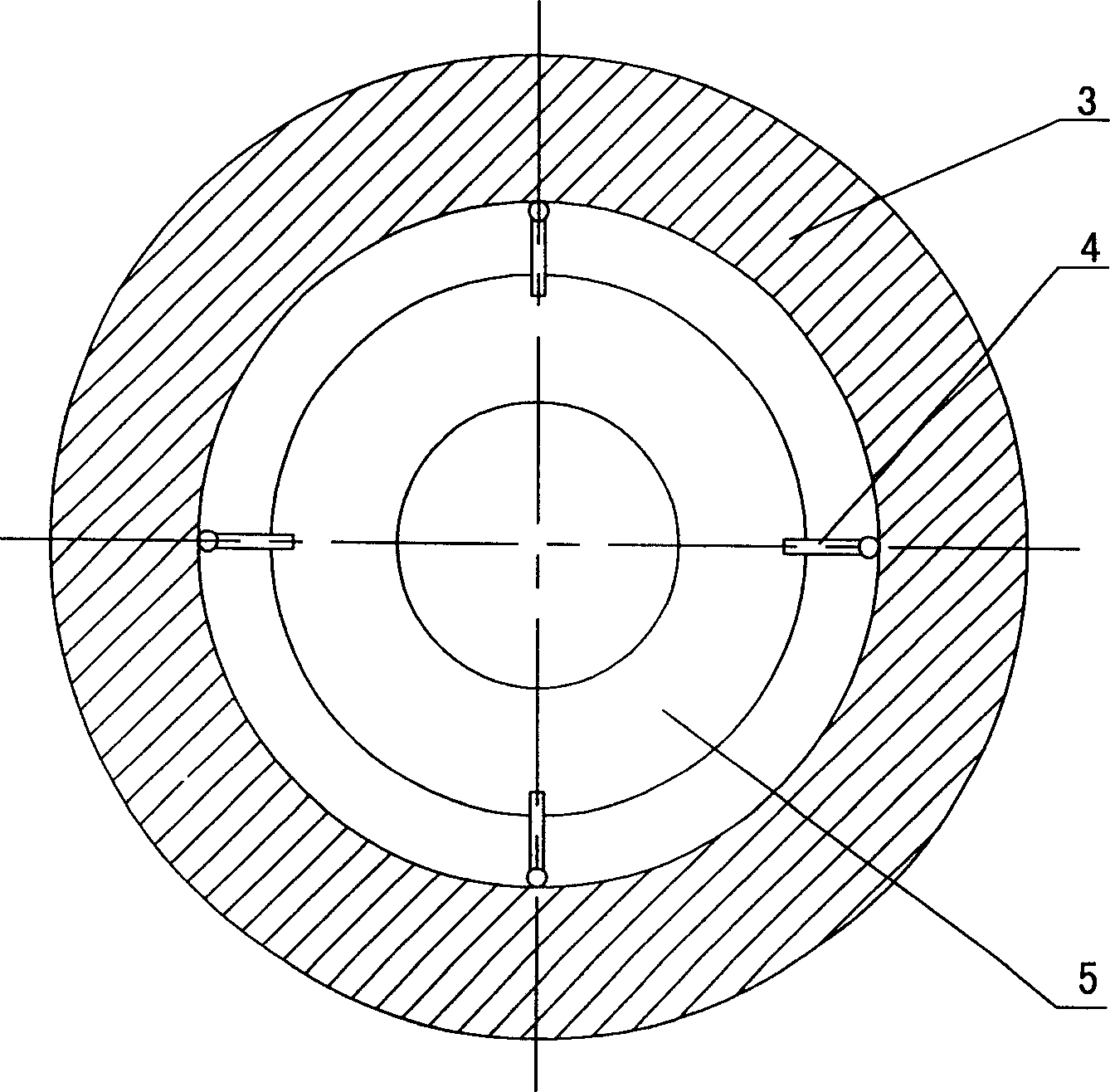

[0022] figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com