Optical disk machine and its Servo control system and optical path modification servo control system

A servo control system and servo control technology, applied in the field of optical path correction servo control system, can solve the problems of inability to effectively control the timely compensation of the skateboard motor, and the inability to notify the skateboard motor servo control unit of the offset of the optical lens.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

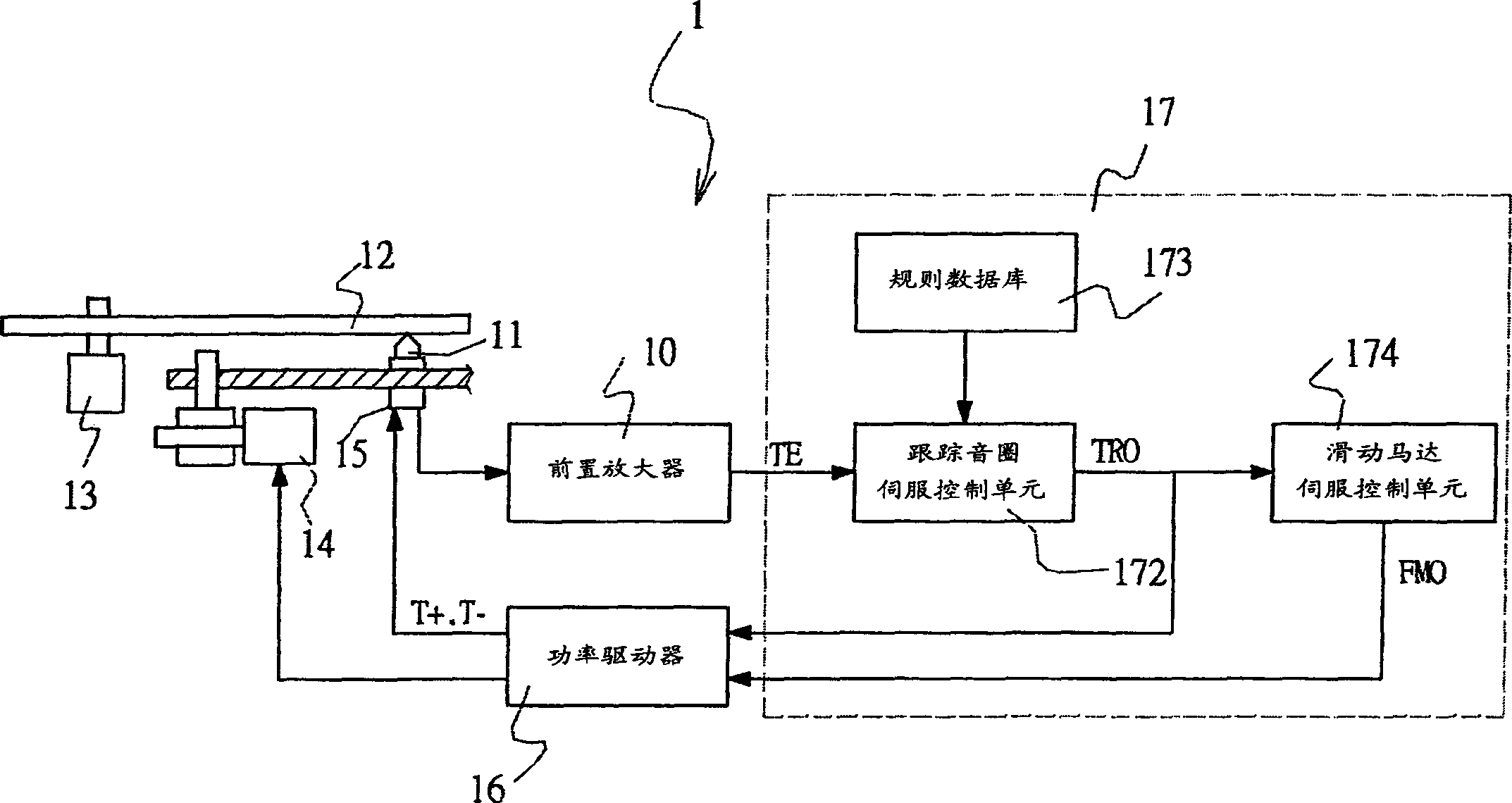

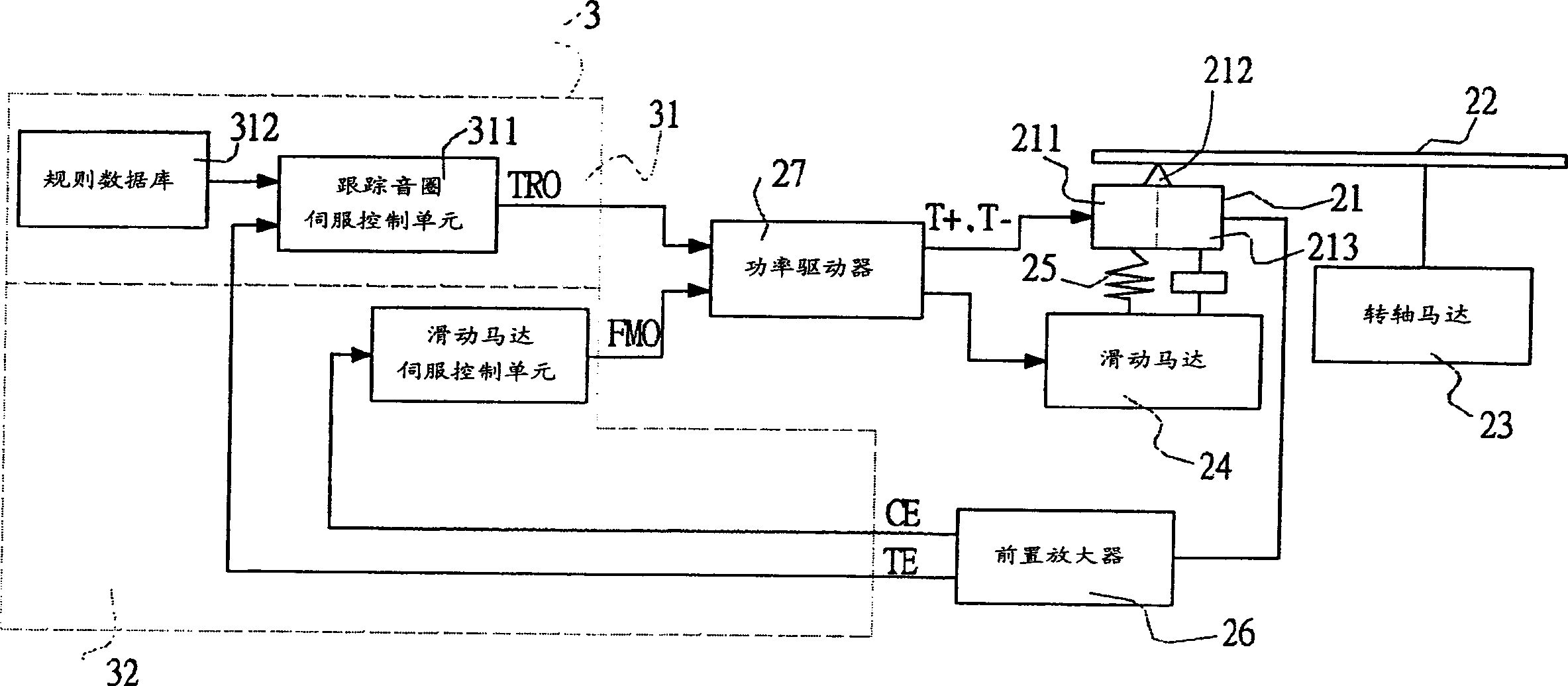

[0016] Please refer to image 3 , image 3 is the structure of the optical disc player 2 according to the preferred embodiment of the servo control system of the present invention. This optical disc drive 2 includes an optical head 21, a spindle motor 23 responsible for rotating the disc 22, a slide motor 24 for carrying the optical head 21 to move, a tracking coil motor 25 on the optical head 21, and a preamplifier 26 And a power driver 27 and a servo control system 3.

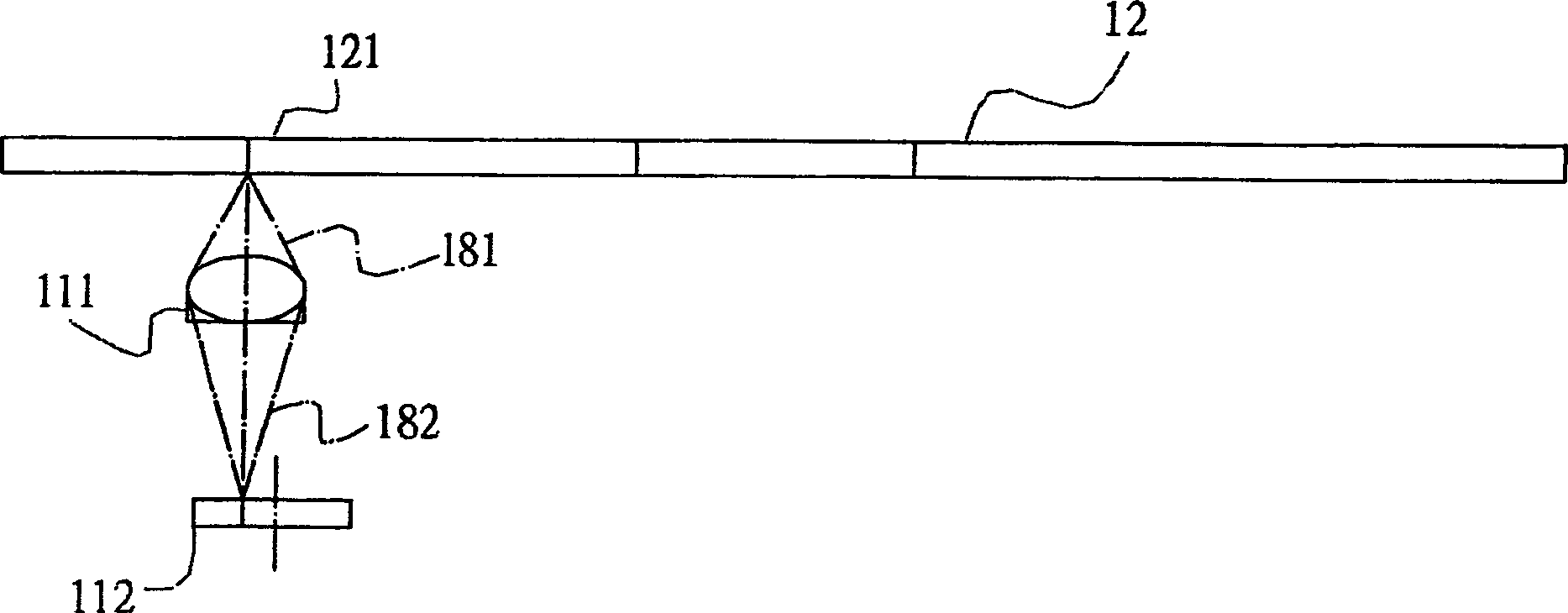

[0017] The optical head 21 includes a light source 211 for outputting light beams to the disc 22, an optical lens 212 (also known as an objective lens) for focusing the light beams, and an optical sensing unit 213. The light source 211 can be a laser light source, and the optical sensing unit The detection unit 213 is used to sense the reflected light beam from the disk 22 through the optical lens 212 and convert it into an electric signal correspondingly, and output it to the preamplifier 26 for amplificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com