Figwort polysaccharide and its production process and use

A production method and technology of Scrophulariaceae, applied in the field of homologous polysaccharide mixtures, to achieve high yield and simple extraction and separation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Wash and dry 500 g of the crude drug Scrophulariaceae Scrophulariae, crush, soak in 5 liters of deionized water at room temperature for 24 hours, and filter. Continue soaking the residue in 2.5 liters of deionized water for 12 hours, filter, combine the filtrates, and concentrate under reduced pressure at 60°C to 1-2 liters. Then precipitate with 95% ethanol, the final concentration of ethanol is 80%, and precipitate for 24 hours. Centrifuge, dissolve the precipitate with 1.25 liters of water, centrifuge, and dialyze with deionized water for 48 to 72 hours. Concentrate under reduced pressure at 60°C and freeze-dry to obtain 8.9 g of total sugars from Scrophulariaceae. Add 2 liters of water to dissolve, add active carbon to treat, remove three times, then concentrate under reduced pressure, centrifuge, and freeze-dry to obtain 3.0 g of total sugar of Scrophulariaceae with a purity of 80%.

Embodiment 2

[0033]Wash and dry 500 g of crude drug Scrophulariaceae Scrophulariae, crush, soak in 5 liters of deionized water at room temperature for 36 hours, and filter. The residue was soaked in 2.5 liters of deionized water for 12 hours, filtered, and the combined filtrates were concentrated to 2 liters under reduced pressure at 50°C. Then precipitate with 95% ethanol, the final concentration of ethanol is 82%, and precipitate for 48 hours. Centrifuge, dissolve the precipitate with 2 liters of water, centrifuge, and dialyze with deionized water for 72 hours. Concentrate under reduced pressure at 50°C and freeze-dry to obtain 9.5 g of total polysaccharides from Scrophulariaceae. Add 2 liters of water to dissolve, add active carbon to treat, remove three times, then concentrate under reduced pressure, centrifuge, and freeze-dry to obtain 3.1 g of total polysaccharides of Scrophulariaceae Scrophulariae with a purity of 80%.

Embodiment 3

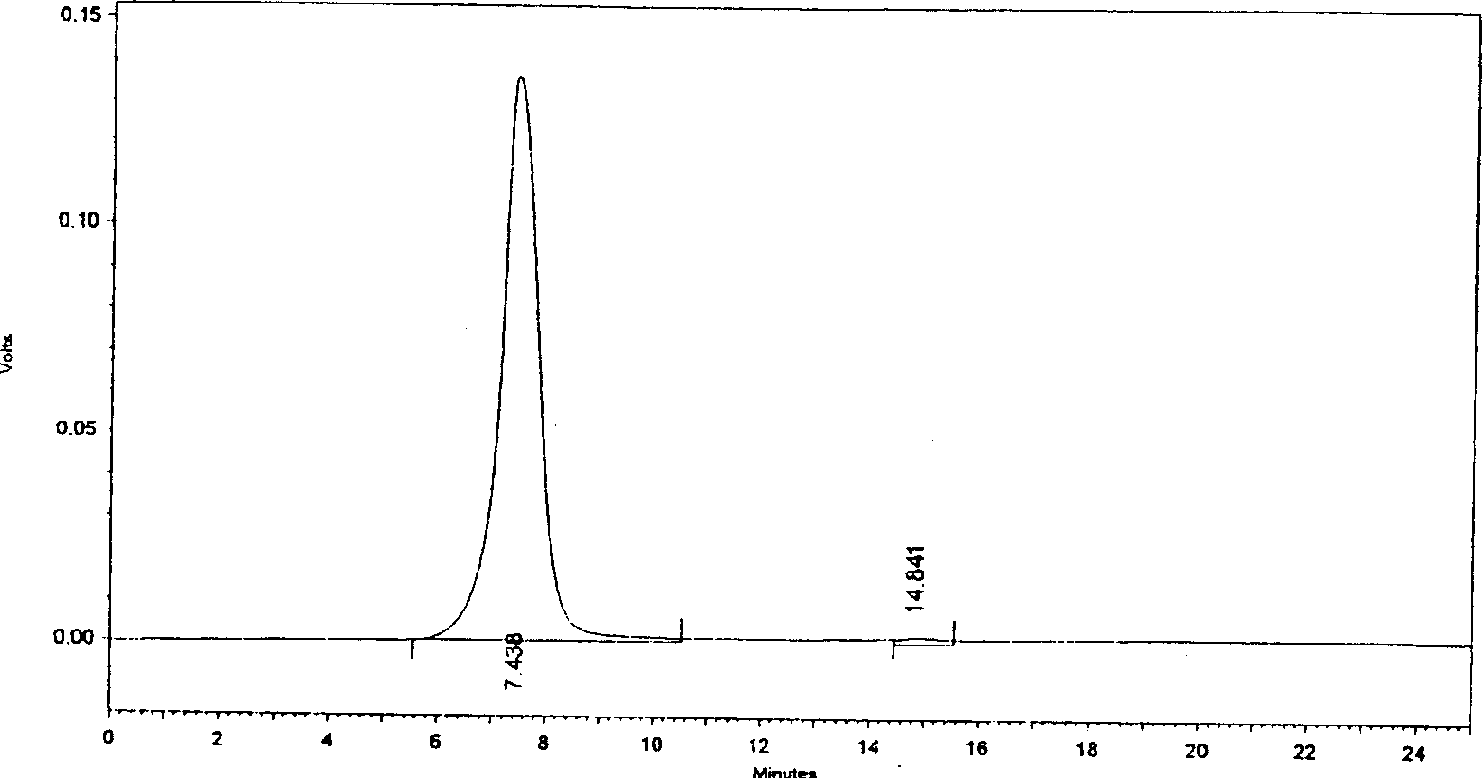

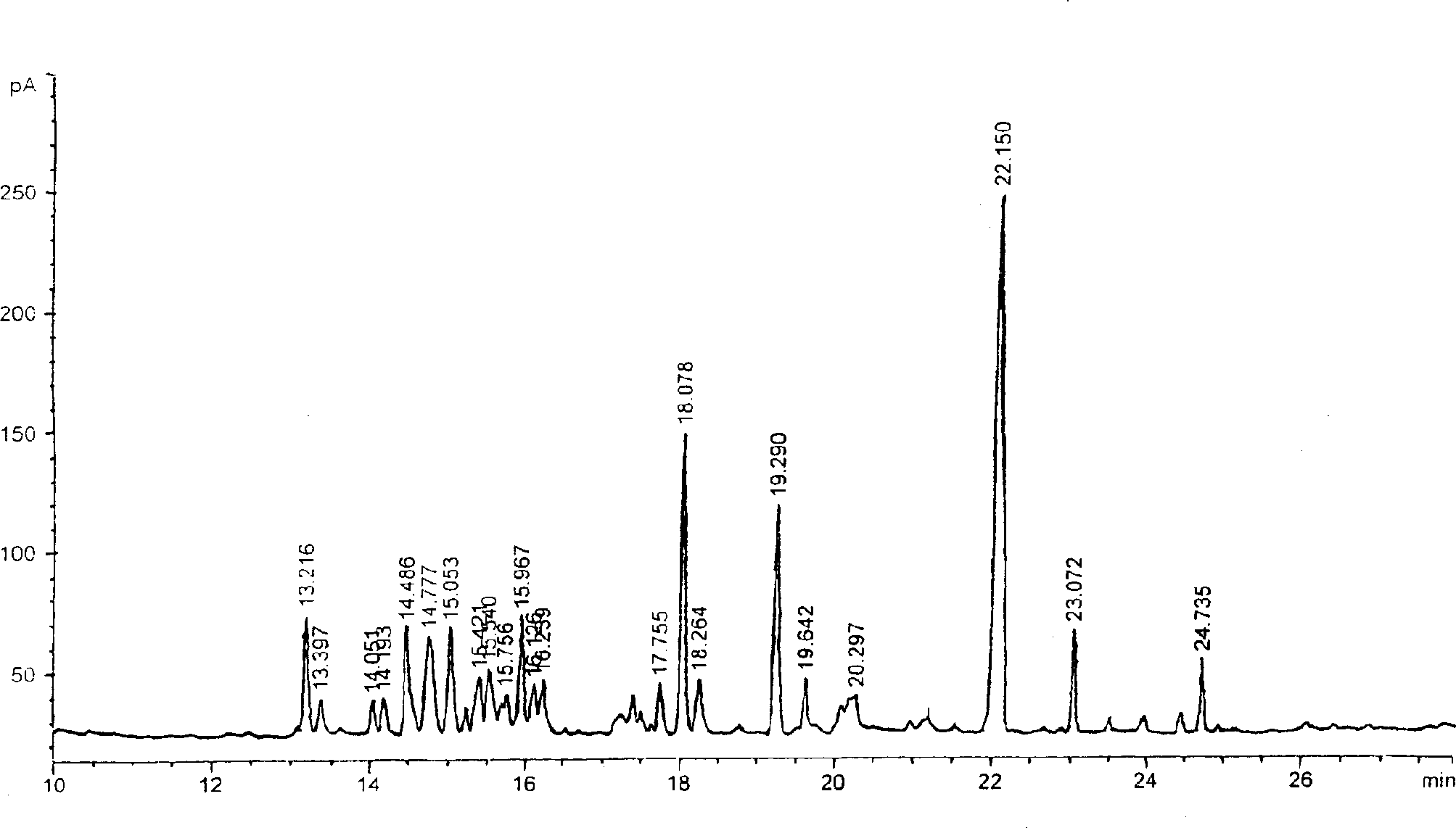

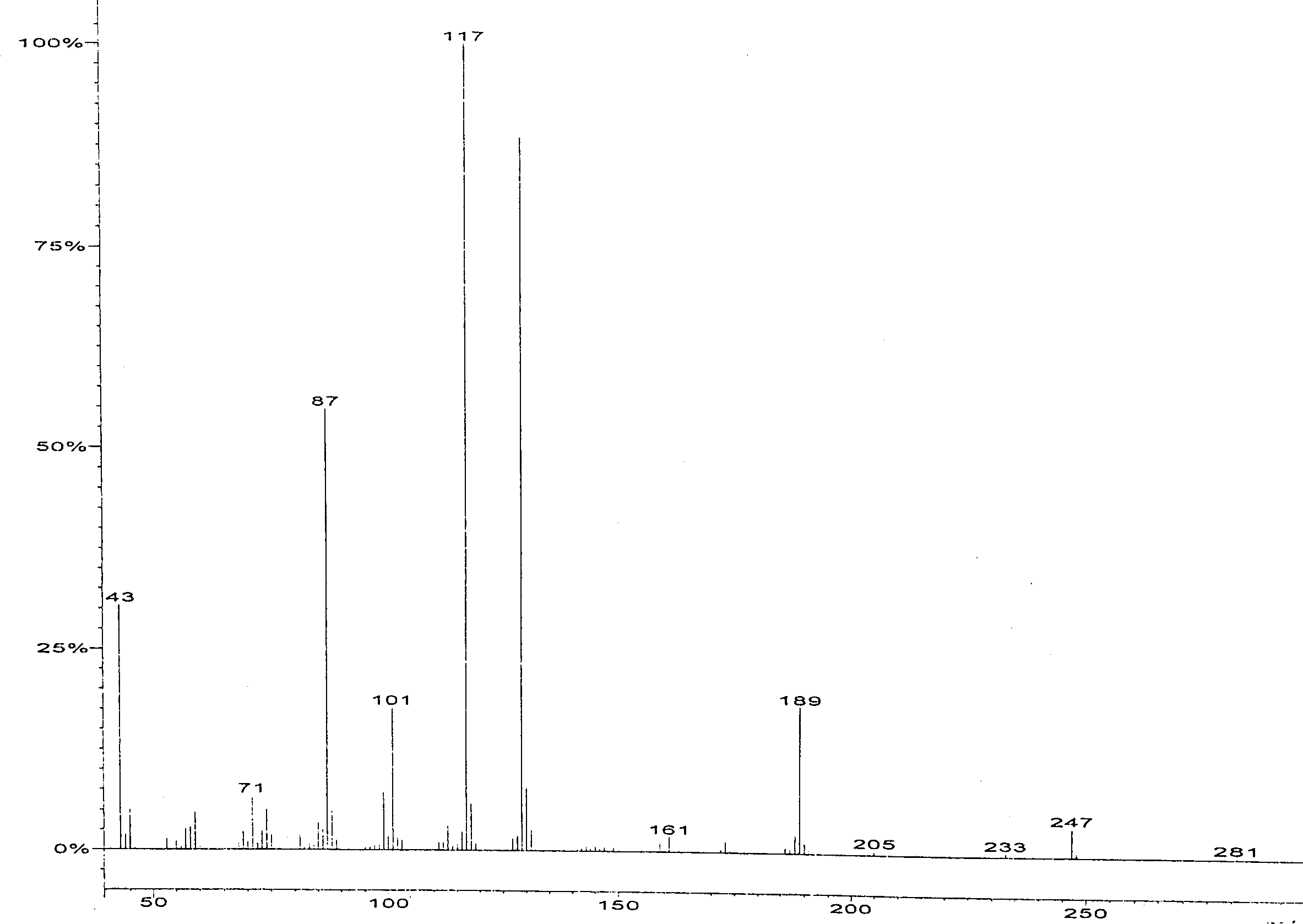

[0035] Scrophulariaceae total sugar was purified by DEAE-Cellulose column chromatography with a purity of 85-90%, and then SephadexG-25 and Sephadex G-75 column chromatography to obtain Scrophulariaceae polysaccharide SnPS-1 with a purity of 99.6%. Specific separation method: weigh 100 mg of total sugar from Scrophulariaceae, dissolve in 1-2 mL of distilled water, and centrifuge (4500 r / min, 10 min). Put the supernatant on a Sephadex G-25 column (1.5cm×100cm), elute with 0.1mol / L NaCl at a flow rate of 0.5mL / min, collect 3-5mL in each tube, and about 37-47 tubes is the absorption peak. After collection, it is purified by Sephadex G-75 column and freeze-dried to obtain pure polysaccharide SnPS-150mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com