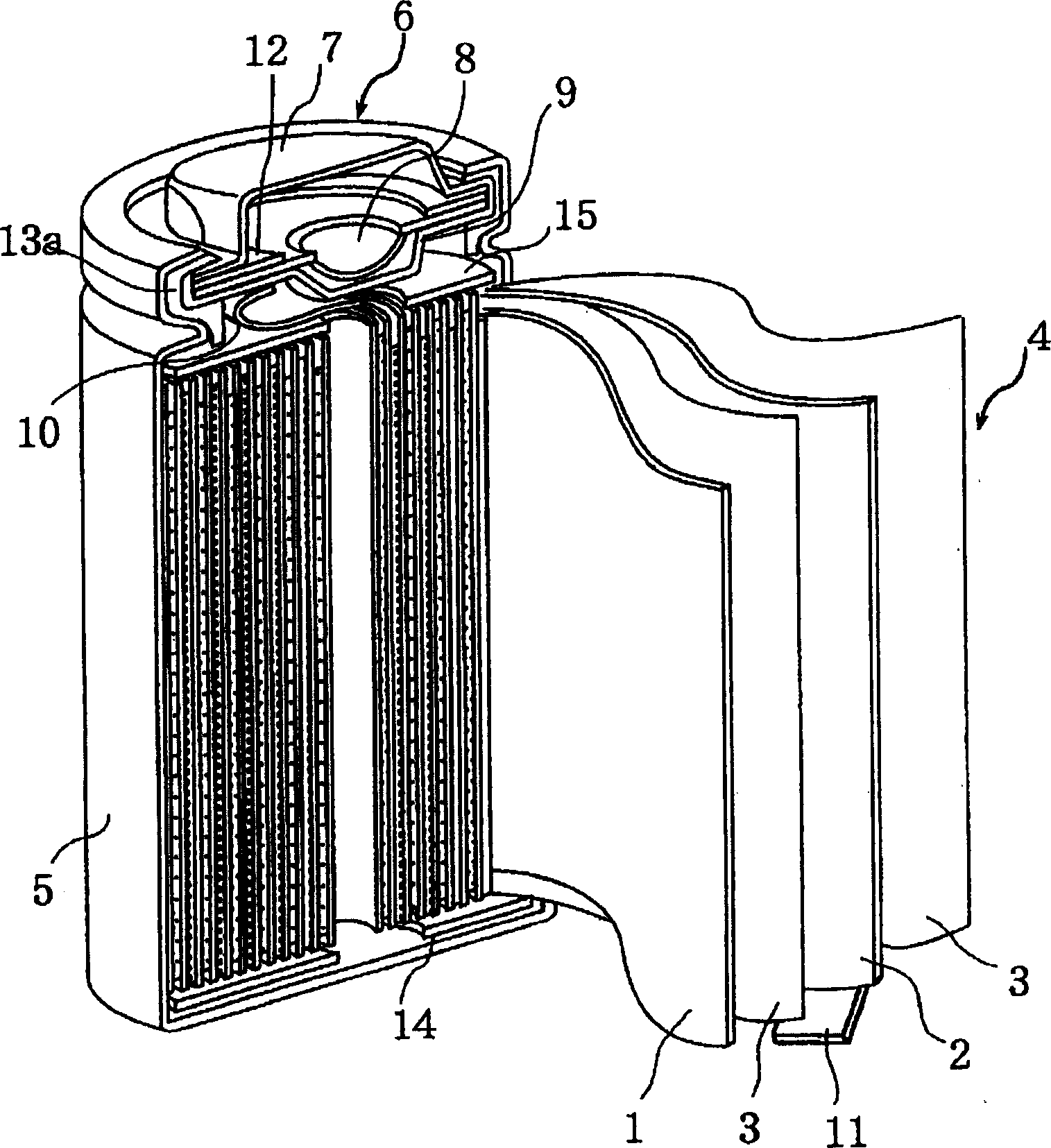

Nonaqueous electrolytic storage battery

A non-aqueous electrolyte and storage battery technology, applied in non-aqueous electrolyte storage batteries, non-aqueous electrolyte storage battery electrodes, battery electrodes, etc., can solve problems such as increased internal resistance, inability to obtain cycle characteristics, and smoke emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

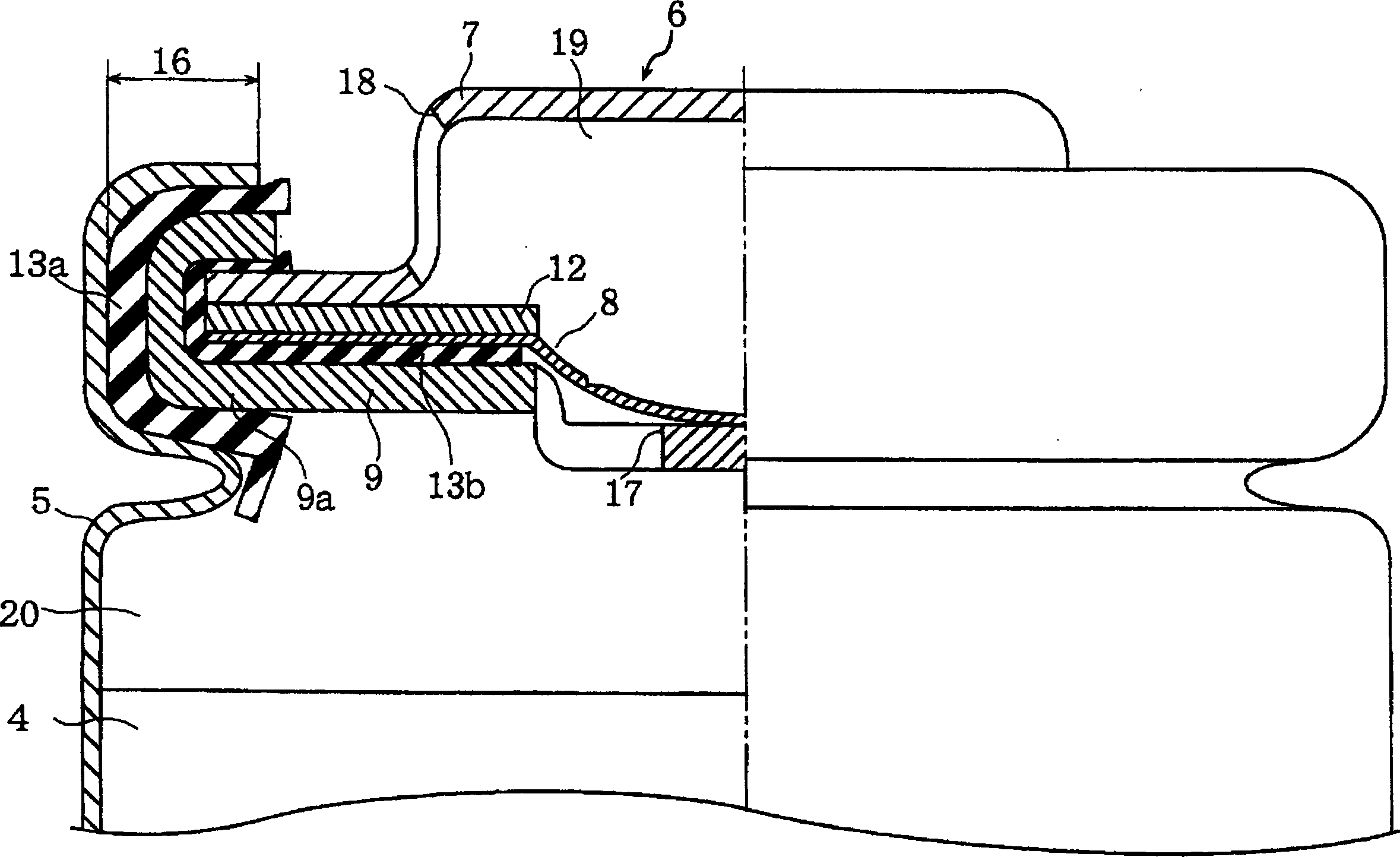

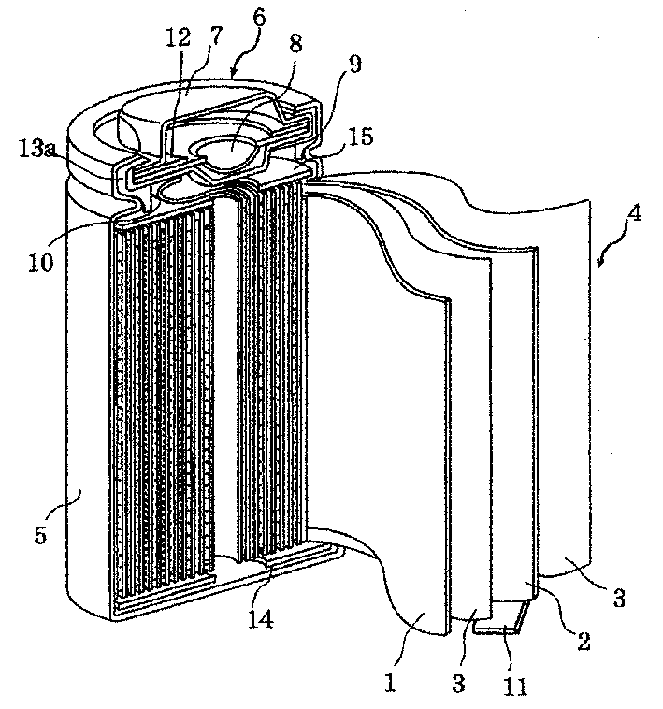

Method used

Image

Examples

Embodiment 1-1

[0060] Lithium cobaltate (LiCoO 2 ) 85 parts by weight of positive electrode active material, 10 parts by weight of carbon-based conductive agent made of acetylene carbon black, 5 parts by weight of binder made of polyvinylidene chloride (PVdF) and N-methyl-2-pyrrolidone ( NMP) mixed to make active material slurry.

[0061] The above-mentioned active material slurry was uniformly coated on both surfaces of a positive electrode core body made of aluminum foil with a thickness of 20 μm using a scraper, and then dried by a dryer. Organic solvents required for slurry preparation are removed by drying. Subsequently, the electrode plate was rolled to a thickness of 0.17 mm with a roll press to produce a positive electrode 1 . The packing density of the active material is 3.5g / cm 3 , the specific surface area of the active material is 0.85m 2 / g.

[0062] 98 parts of mass are dispersed in water with negative electrode active material made of graphite and styrene-butadiene rubb...

Embodiment 1-2

[0067] Except not adding phenylcyclohexane, 3 parts by mass of tert-amylbenzene (TAB) was added, and the same operation as the above-mentioned Example 1-1 was performed to prepare the battery A2 of the present invention of Example 1-2.

Embodiment 1-3

[0069] Change the addition amount of phenylcyclohexane to 1 part of quality, and add 1 part of quality tert-amylbenzene (TAB), and operate in the same way as above-mentioned embodiment 1-1 except that, make embodiment 1-3 The battery A3 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com