Glass blank for shape and producing method thereof, glass product producing method therewith

A glass blank, pre-forming technology, applied in glass forming, glass pressing, glass manufacturing equipment, etc., can solve problems such as a lot of time and cost, uneven surface layer of glass blank, etc., to prevent fusion or cloud spots. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

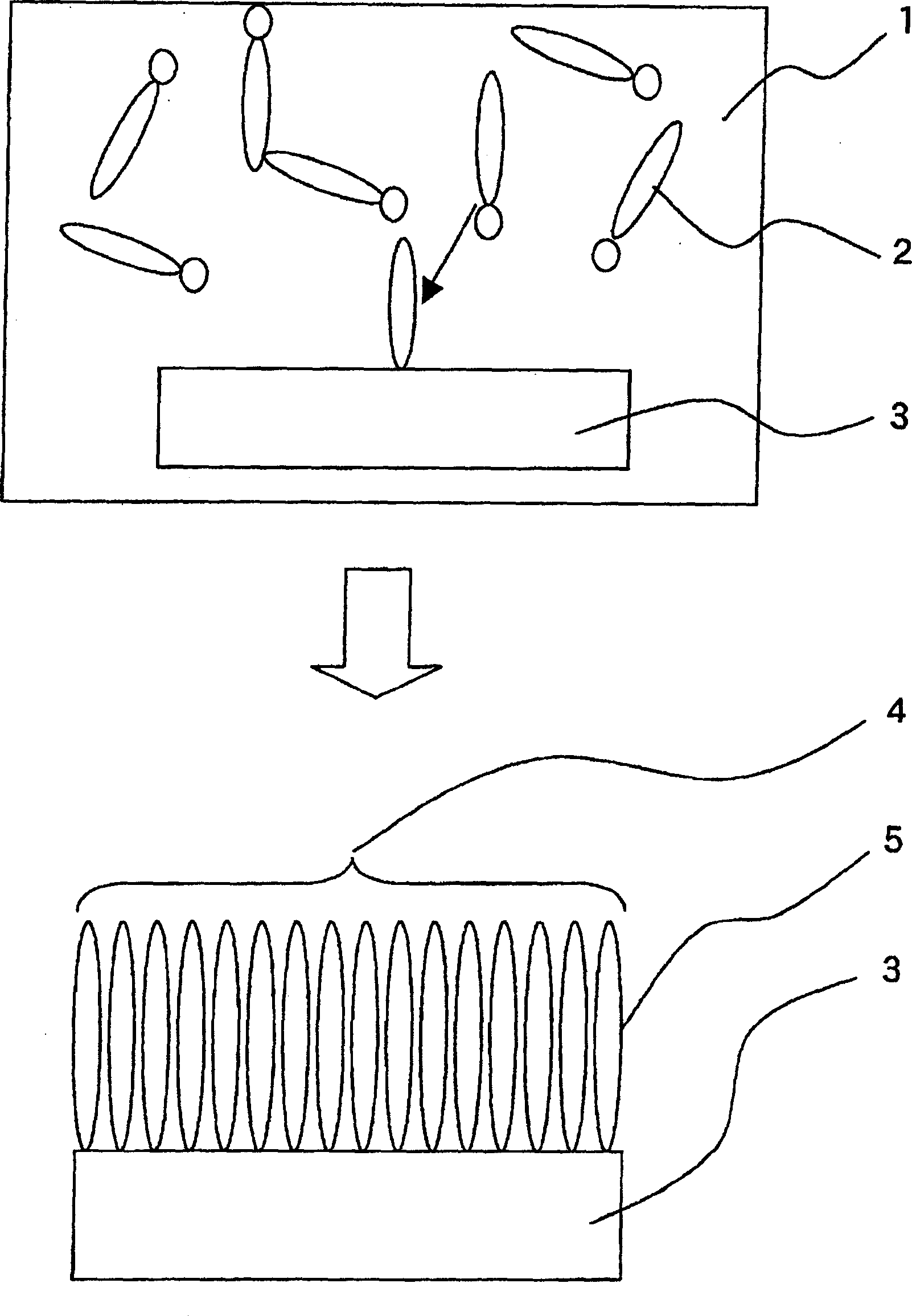

Method used

Image

Examples

Embodiment 1

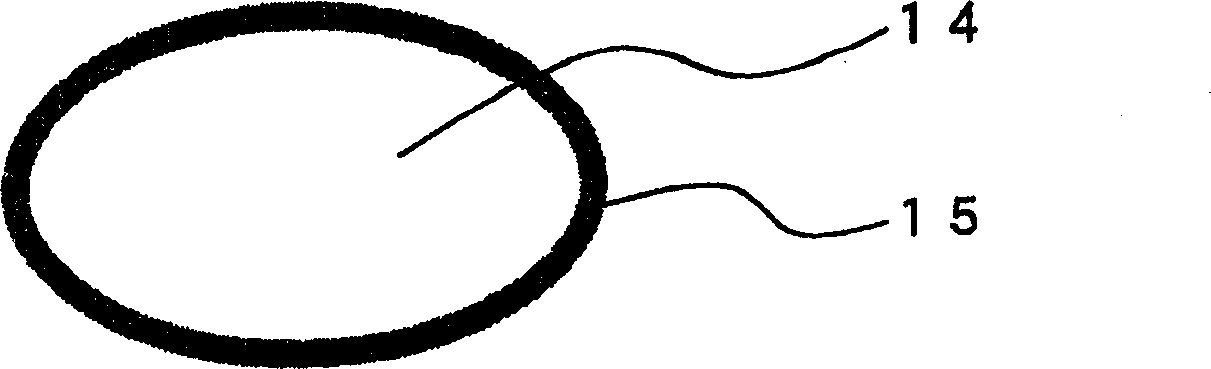

[0171] A glass blank in which a self-assembled film is formed on the surface of a preformed core glass is prepared. That is, n-octadecyltrichlorosilane (CH 3 (CH 2 ) 17 SiCl 3 ) was diluted to 1 wt % in a coating solution prepared, and the glass blank was immersed at 20° C. for 60 seconds, then taken out from the coating solution, washed, and dried at room temperature for about 30 minutes. The optical glass used as core glass (glass blank) has a glass transition temperature of 520°C, a refractive index of 1.69350, and a linear expansion coefficient of 69×10 -7 / °C, borate-based glass containing alkali metal oxides as volatile components.

[0172] Since IR-RAS can only be used for partial analysis, the JASCO FT / IR620 device is used to analyze any 10 points on the surface of the glass blank with IR-RAS, and the results are as follows: Figure 5 As shown, peaks derived from the self-assembled film were observed at all 10 measurement points, confirming that the film formed on...

Embodiment 2~9

[0186] Except changing glass, coating solution, film-forming conditions, etc. as shown in Tables 3 to 5, others are the same as in Example 1, making a glass blank forming a self-assembled film, continuously pressing with the same mold, and observing that the number of times of pressing reaches 500. The appearance of the second-time optical element, the results are shown in Tables 3-5, there are almost no cloud spots, white turbidity and cracks, and the appearance quality is good or excellent.

Embodiment 10

[0188] Using the glass in Table 5, a preformed glass blank was immersed for 30 seconds in a coating solution prepared by diluting trichlorovinylsilane, the starting material of the self-assembled film, to 20 wt% with anhydrous benzene to form a film. , 10 points on the surface of the glass blank were analyzed by IR-RAS, and as a result, peaks were confirmed at 8 points.

[0189] The average film thickness evaluated by ESCA was 0.3 nm, 0.2 nm in the central part of the glass blank, and 0.3 to 0.4 nm in the peripheral part. from pure water and CH 2 I 2 The surface energy analyzed by the wetting angle measurement is 38~52mJ / m 2 .

[0190] As in Example 1, the same mold was used for continuous pressing, and the appearance of the optical element pressed 500 times was observed. The results are shown in Table 5. There are almost no cloud spots, white turbidity and cracks, and the appearance quality is very good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface free energy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com