Sticky crude petroleum pretreatment method

A pretreatment and crude oil technology, applied in the petroleum industry, refining hydrocarbon oil, etc., can solve problems such as difficult operation and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

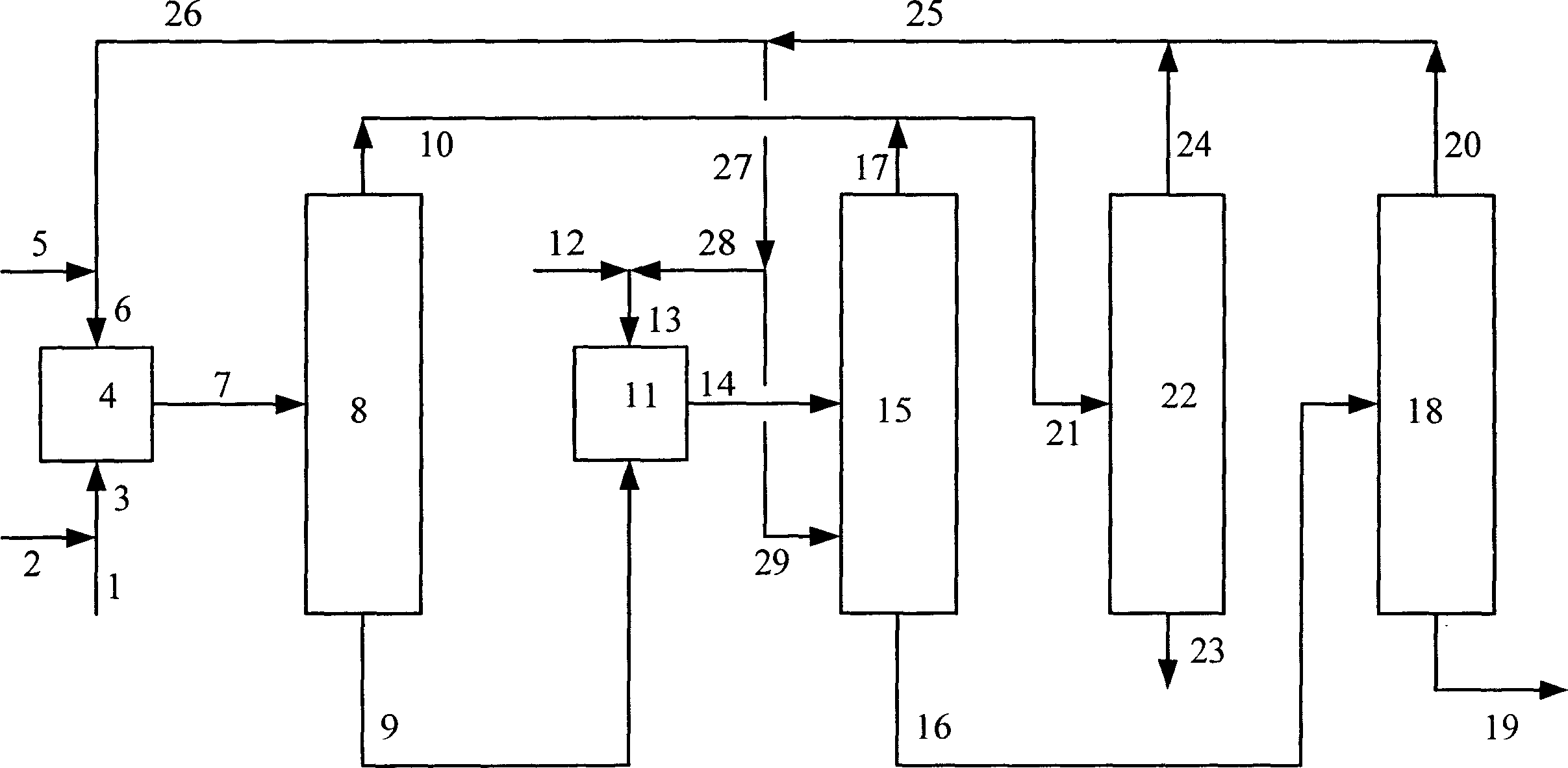

Method used

Image

Examples

Embodiment 1

[0027] The properties of the heavy oil used in the test are as follows: Density (20°C) 0.9428g / cm 3 , Viscosity (80°C) 309.12mm 2 / s, salt content 683mgNaCl / L, calcium content 1652mg / kg, acid value 13.8mgKOH / g. Get this heavy oil 100g, add 20g kerosene, then add the decalcification agent that is made of 1g aminomethine phosphoric acid, 55g isopropanol, 44g water. Stir at 70 °C for 20 min, and settle at 70 °C for 1 h, separate the oil phase, add another 5 g Na to the oil phase 2 CO 3 , 70g isopropanol, 25g water deacidification agent. Stir at 70° C. for 20 minutes, settle at 70° C. for 10 hours and separate the oil phase, then add 80 g of isopropanol aqueous solution (isopropanol concentration is 70%) to the oil phase, stir for 10 minutes, and settle for 1 hour. The oil phase is separated, and the solvent is distilled off at 150°C to obtain a pretreated heavy oil with an acid value of 1.2mgKOH / g, a calcium content of 100ppm, and a salt content of less than 3mgNaCl / L.

Embodiment 2

[0029] The viscous oil that adopts, decalcifying agent are identical with embodiment 1, and deacidifying agent adopts NaHCO 3 , isopropanol and water, the processing conditions are the same as in Example 1, the acid value of the treated heavy oil is 1.3mgKOH / g, the calcium content is 120ppm, and the salt content is less than 3mgNaCl / L.

Embodiment 3

[0031] The decalcifying agent uses hydroxyethylidene diphosphoric acid, isopropanol and water, and other process conditions are the same as in Example 1. The acid value of the treated heavy oil is 1.3 mgKOH / g, the calcium content is 100 ppm, and the salt content is less than 3 mgNaCl / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com