Method for augmenting spiral torsion, optical active compound, liquid crytal composite and liquid crystal display element untaining it

一种光学活性、扭曲率的技术,应用在光学、液晶材料、非线性光学等方向,达到增大HTP值、液晶上限温度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0167] Preparation of Preparation Method 3 General Formula (VIII-h)

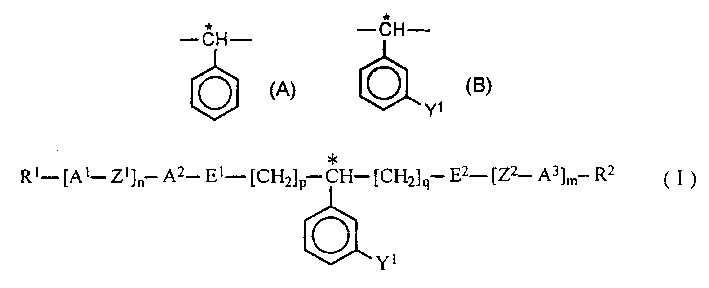

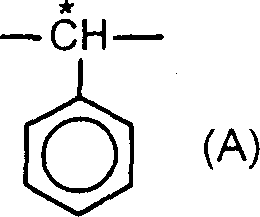

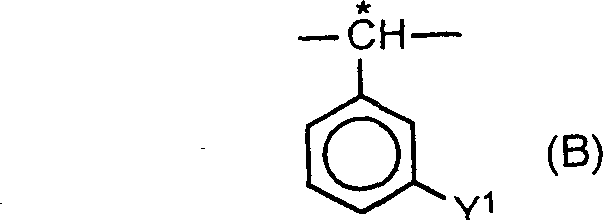

[0168] In general formula (I), A 2 Represents 1,4-phenylene, E 2 Indicates a single bond, m and q indicate 0, E 1 In the case of an oxygen atom.

[0169]

[0170] (where, *, R 1 , R 2 ,Z 1 , Y 1 、A 1 , p and n represent the same meaning as in general formula (I). )

[0171] The compound represented by the general formula (VIII-h) can be prepared by etherifying the phenol derivative represented by the general formula (VIII-f) and the compound represented by the general formula (VIII-g) by a fixed method.

[0172] Preparation of Preparation Method 4 General Formula (VIII-h2)

[0173] In general formula (I), A 2 Represents 1,4-phenylene, E 2 Represents a single bond, m+q represents 1, 2, 3 or 4, E 1 In the case of an oxygen atom.

[0174] In the reaction formula described in Preparation Method 3, by replacing the general formula (VIII-g) with the general formula (VIII-i)

[0175]

[0176] (...

Embodiment 1

[0280] The compound represented by formula (XI-a) can be produced by the following method.

[0281]

[0282] Under ice-cooling, the dichloromethane solution of (R)-2-(3-methoxyphenyl)propionyl chloride was added dropwise to the dichloromethane suspension of aluminum chloride. After stirring at the same temperature for 15 minutes, a dichloromethane solution of trans-4-propylcyclohexylbenzene was added dropwise. After the reaction was completed, the reaction system was added to ice water, and dichloromethane was added to separate the organic layer. The organic layer was washed twice with water and then with saturated brine. The aqueous layer was washed with dichloromethane and combined with the organic layer, and the solvent was concentrated to obtain the crude product of (R)-1-(4-cyclohexylphenyl)-2-(3-methoxyphenyl)-propane-1 ketone . Hydrazine monohydrate was added to the ethylene glycol solution of the obtained crude product, and it stirred at 110 degreeC, removing by-...

Embodiment 2

[0284] Formula (XI-b) was prepared in the same manner as in Example 1.

[0285]

[0286] (S)-1-{3,3,3,-trifluoro-2-(3-methoxyphenyl)propyl}-4-(trans-4-propylcyclohexyl)benzene

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com