Cathode material for nonaqueous electrolyte secondary battery, its producing method and nonaqueous electrolyte secondary battery

A non-aqueous electrolyte and secondary battery technology, which is applied in the direction of non-aqueous electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problem of reduced charge/discharge cycle characteristics, achieve excellent charge/discharge cycle characteristics, and suppress quality degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0031] First, the cathode material for a nonaqueous electrolyte secondary battery of the present invention (hereinafter, the "cathode material for a nonaqueous electrolyte secondary battery" is also simply referred to as "cathode material") of the present invention is described.

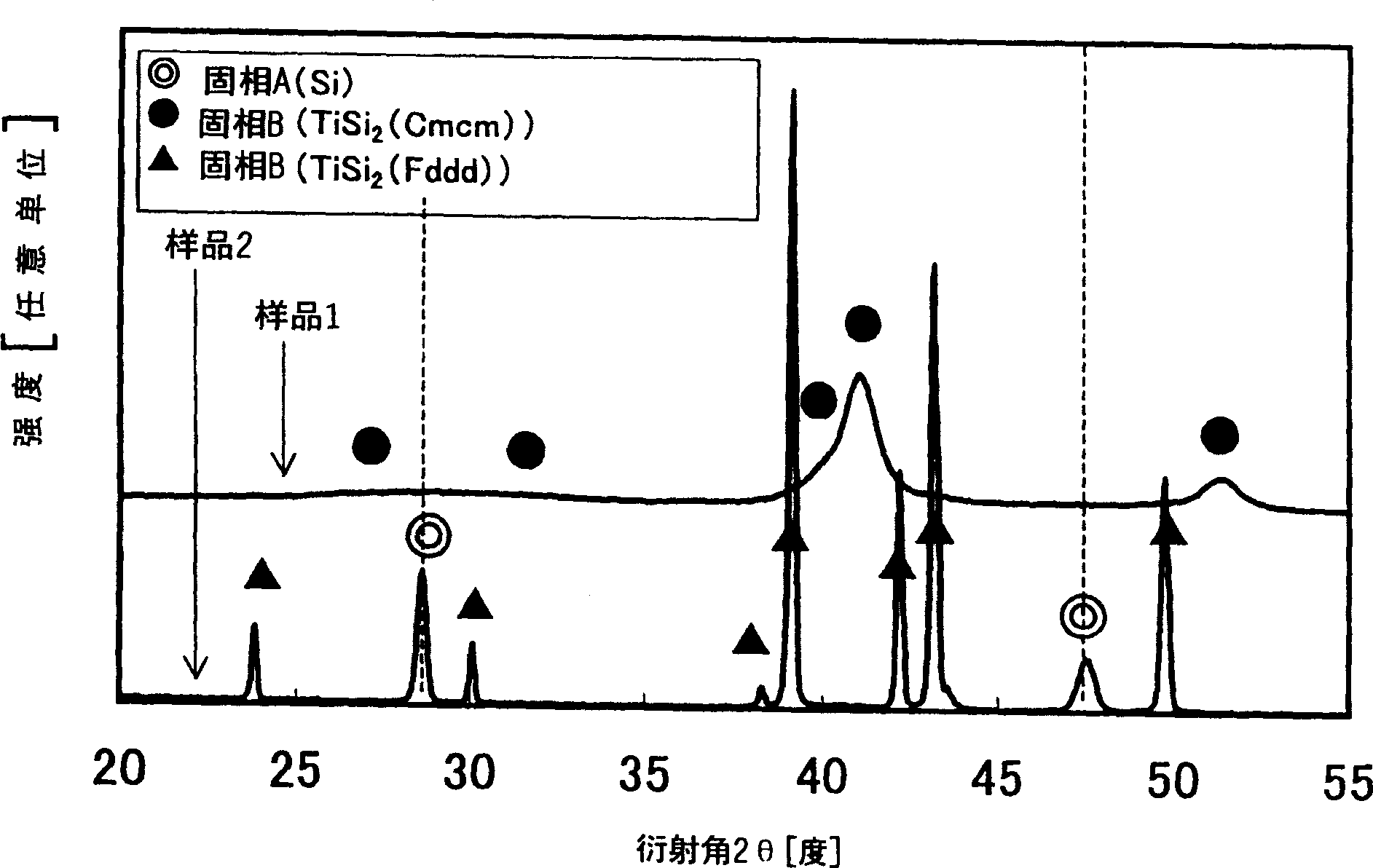

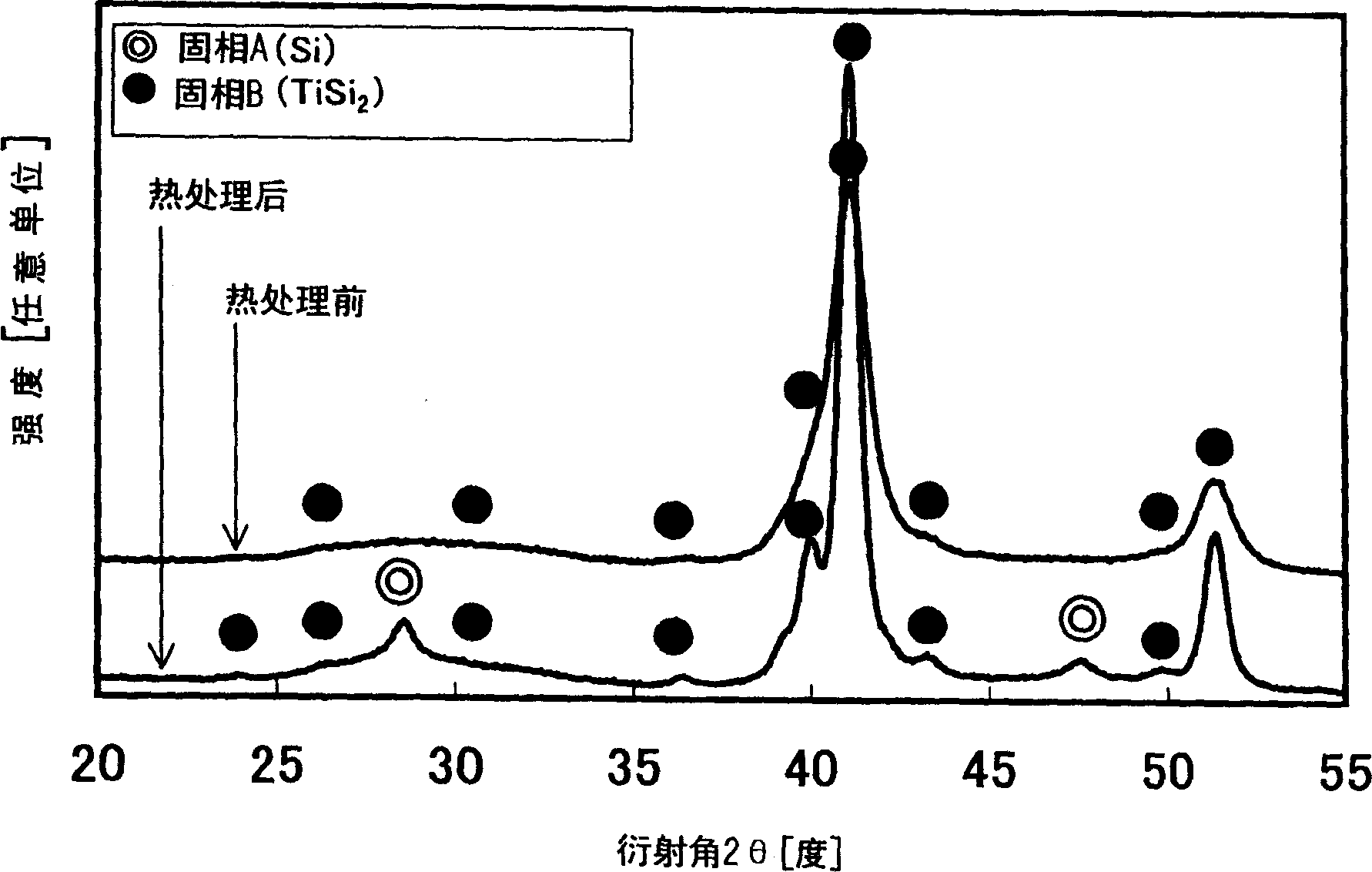

[0032] The cathode material according to the present invention is a cathode material capable of absorbing and desorbing lithium (Li) for a non-aqueous electrolyte secondary battery; A structure that is completely or partially covered by solid phase B. The cathode material may be in at least one form selected from, for example, solid solution, metal compound and alloy.

[0033] Here, the solid phase A contains at least one element selected from silicon, tin and zinc. Solid phase B includes: at least one element described above contained in solid phase A, and at least one element selected from group IIA elements, transition elements, group IIB elements, group IIIB elements, and group IVB elements.

...

Embodiment approach 2

[0083] Next, the production method of the cathode material used in the nonaqueous electrolyte secondary battery of the present invention will be described.

[0084] As long as the above-mentioned solid phase A and / or solid phase B can be controlled, the production method of the cathode material of the present invention is not particularly limited. For example, in the cathode material production step, the size and condition of the solid phase A can be easily controlled by using mechanical blending (mechanical fusion process).

[0085]For example it is possible to utilize a method comprising the steps of: 1) combining at least one element selected from silicon, tin and zinc with a compound comprising elements selected from group IIA, transition elements, group IIB elements, group IIIB elements and group IVB mixing materials of at least one element of the elements, and melting the resulting material; 2) forming a solidified material by quenching and solidifying the molten materia...

Embodiment approach 3

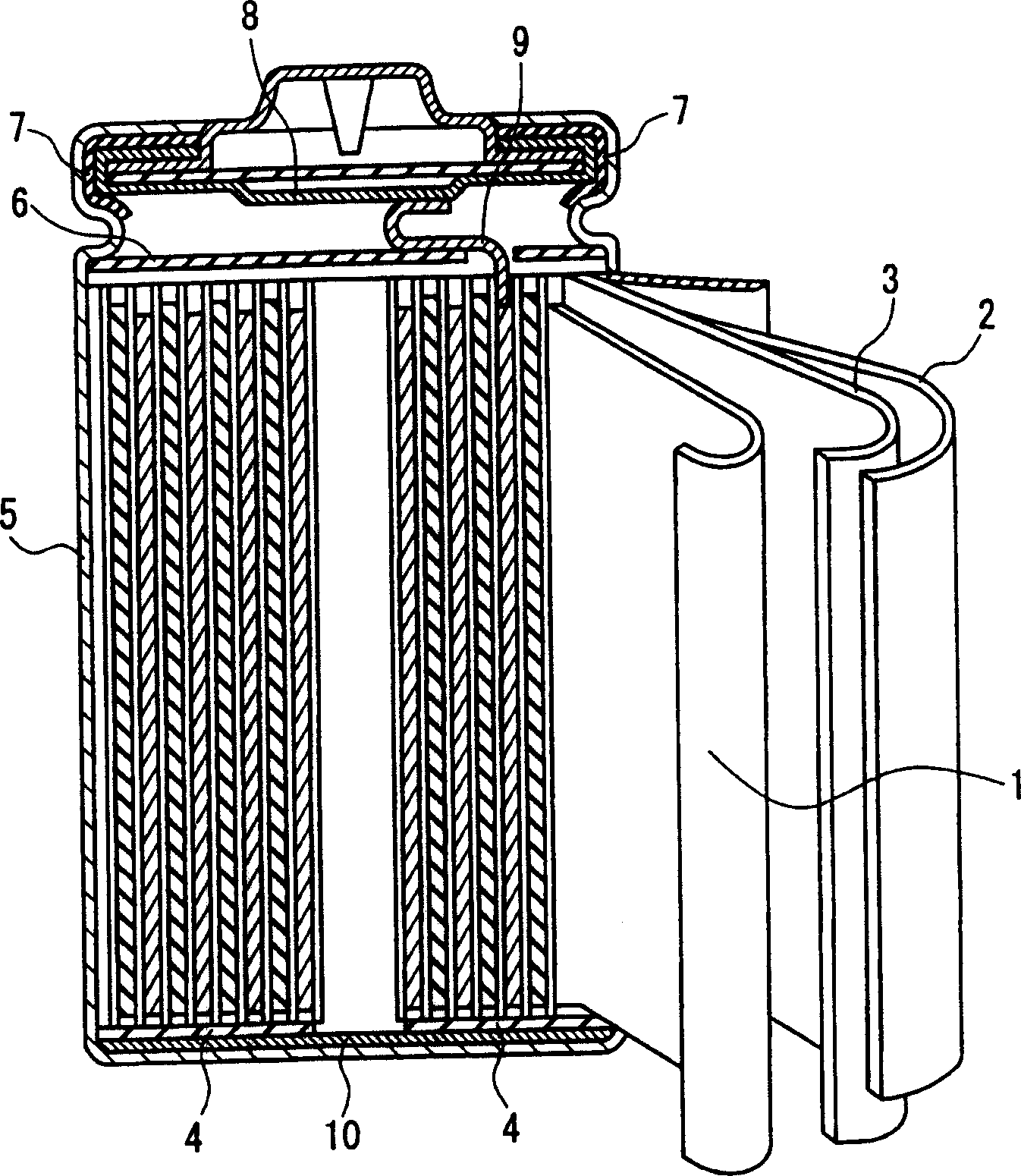

[0090] In the following, reference will be made to image 3 The nonaqueous electrolyte secondary battery of the present invention is described.

[0091] image 3 is a schematic diagram showing an example of the nonaqueous electrolyte secondary battery of the present invention.

[0092] For example, it can be obtained in the following way image 3 The non-aqueous electrolyte secondary battery shown in . First, an anode 1 and a cathode 2 that reversibly absorb and desorb lithium ions are laminated with a separator 3 interposed therebetween, and the obtained laminate is rolled up. The rolled laminate was placed in a box 5 equipped with a lower insulating plate 4 on the bottom surface, and the entire box was filled with an electrolyte having lithium ion conductivity, and then an upper insulating plate 6 was placed. The resulting structure is then sealed by a gasket 8 with a gasket 7 at its periphery. The anode 1 and the cathode 2 can be electrically connected to external term...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com