Photoelectric conversion device and image pick-up system using the photoelectric conversion device

A technology for photoelectric conversion and photoelectric conversion area, which is applied in the direction of electric solid devices, parts and components of TV systems, electrical components, etc., and can solve problems such as deterioration of carrier efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

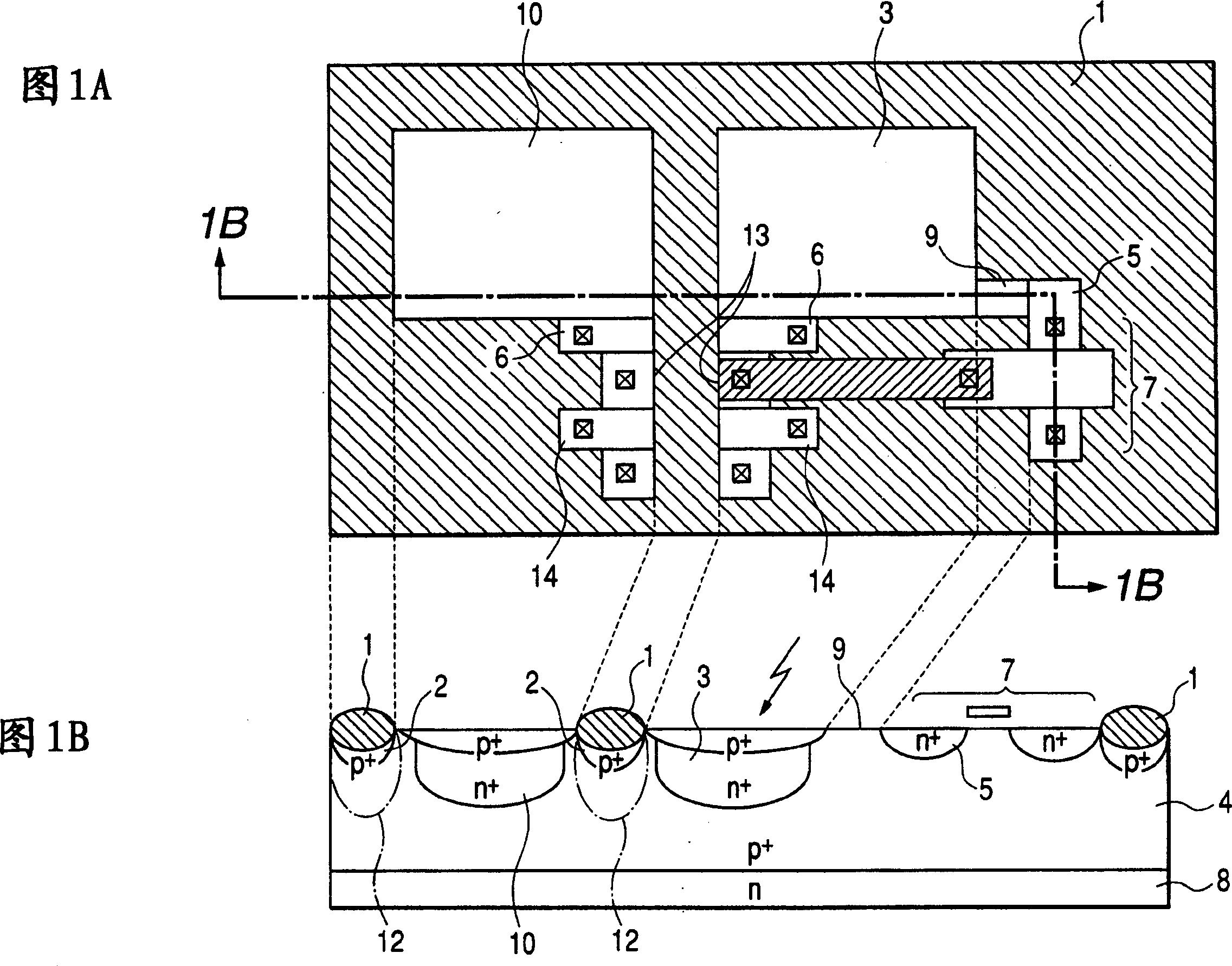

[0025] 1A is a plan view showing the configuration of a photoelectric conversion device according to a first embodiment of the present invention, and FIG. 1B is a typical cross-sectional view taken along line 1B-1B in FIG. 1A . As shown in Figures 1A and 1B, a photodiode (becoming a photoelectric conversion region) 3 is formed in the p well 4, and the charge accumulated in the photodiode 3 is due to the potential of the transfer electrode 6 becoming a high level, and the floating diffusion (floating diffusion) region 13 and the gate of the MOS transistor 7 connected to the floating diffusion region 13, and the output signal is amplified by the MOS transistor 7. Here, as shown in FIG. 1B, for the photodiode 3, the photodiode (becoming a photoelectric conversion region) 10 of an adjacent pixel is arranged via the selective oxide film 1 (surrounding the photodiodes 3 and 10). 2 is The channel blocking region (channel blocking layer) under the selective oxide film 1, 5 is the drai...

Embodiment approach 2

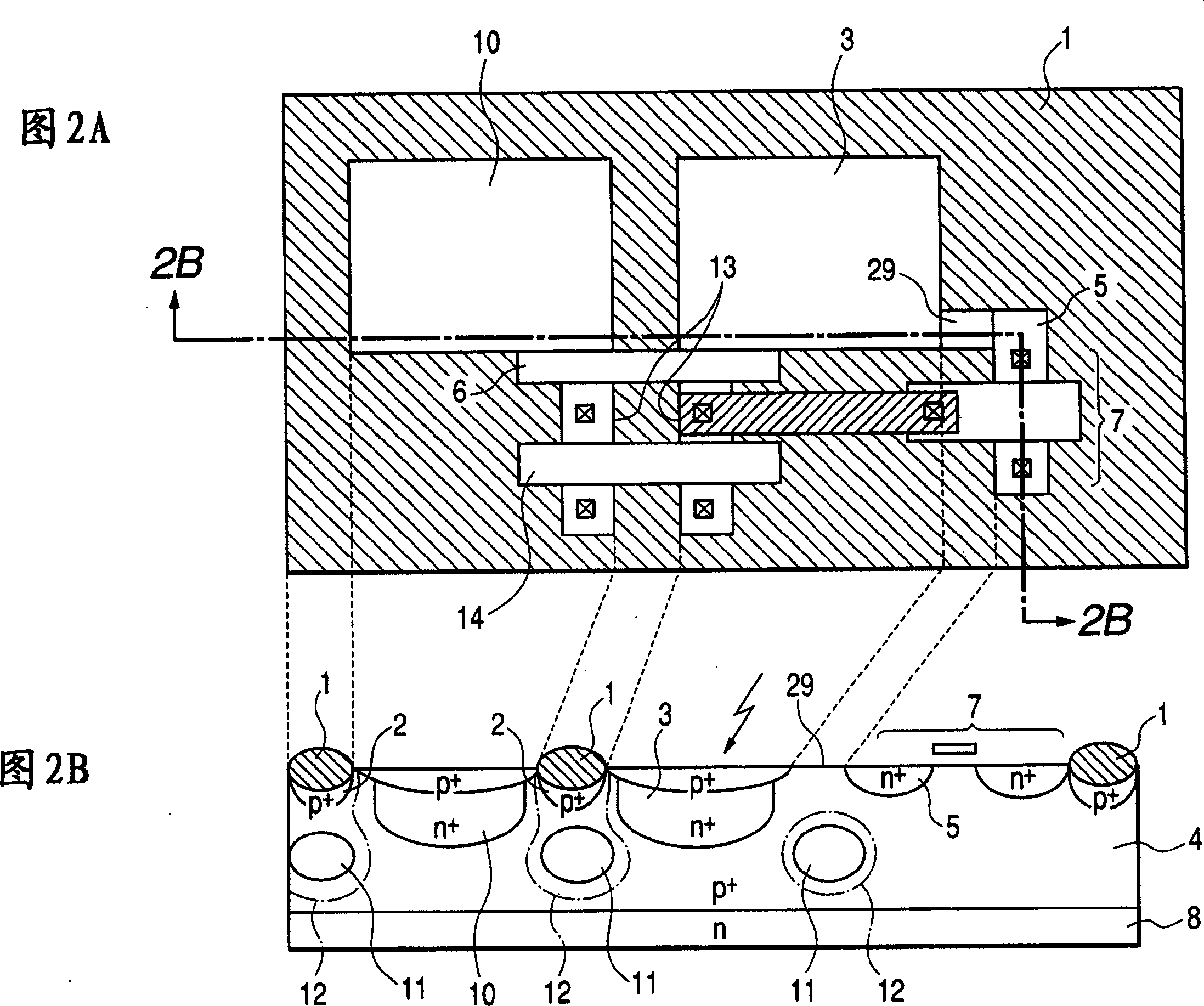

[0029] 2A is a plan view showing the configuration of a photoelectric conversion device according to a second embodiment of the present invention, and FIG. 2B is a typical cross-sectional view taken along line 2B-2B in FIG. 2A. In addition, in FIGS. 2A and 2B , the same components as those in FIGS. 1A and 1B are given the same reference numerals and their descriptions are omitted.

[0030] Compared with the first embodiment, in this embodiment, under the channel stop region 2, a p-type buried barrier layer (which will become a buried isolation region) 11 is provided to surround the photodiodes 3 and 10. . Similar to the overflow channel 9 of the first embodiment, 29 is an overflow channel as a defect region. Specifically, it is a region where the oxide film 1 and the channel stopper region 2 are not selected. In Fig. 2B, although the impurity distribution diagram is also shown, the potential distribution is a region larger than the channel stop region 2 and the barrier layer...

Embodiment approach 3

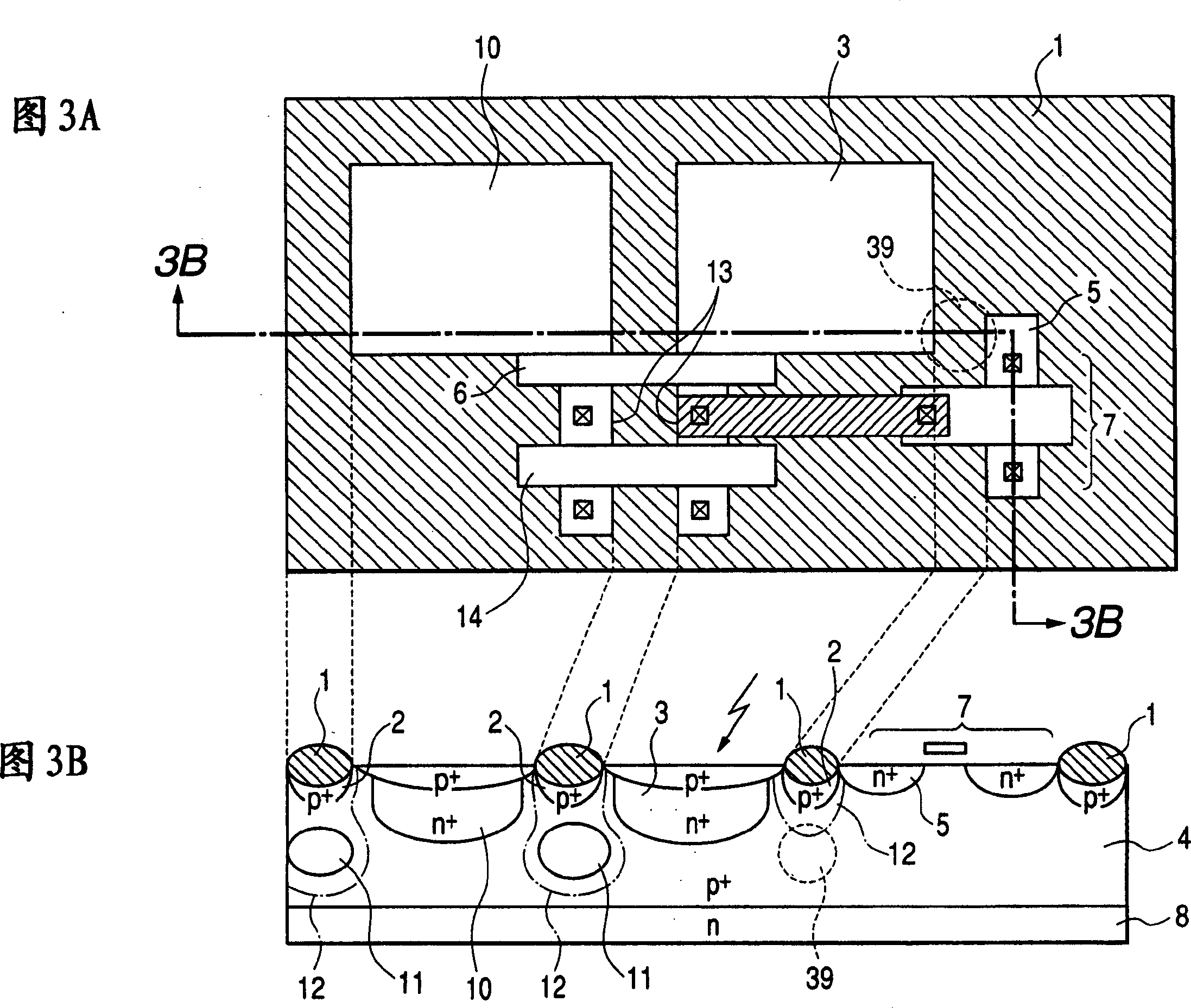

[0033] 3A is a plan view showing the configuration of a photoelectric conversion device according to a third embodiment of the present invention, and FIG. 3B is a typical cross-sectional view taken along line 3B-3B in FIG. 3A. In addition, in FIGS. 3A and 3B , the same components as those in FIGS. 2A and 2B are given the same reference numerals and their descriptions are omitted.

[0034] This embodiment is the same as Embodiment 2, the photodiodes 3 and 10 are surrounded by the buried barrier layer 11 and the surface channel stop layer 2, and only the defect region between the photodiode 3 and the drain region 5 39, no barrier layer 11 is provided.

[0035] In Fig. 3B, the distribution of the potential is a region larger than the channel blocking region 2 and the barrier layer 11, forming the respective surroundings of the channel blocking region 2 and the potential barrier layer 11, or the channel blocking region 2. A vertical wall such as the region (barrier) 12 indicated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com