Phosphorus-eliminating purification process of vanadium-containing chamotte leachate

A technology of leaching liquid and vanadium clinker, which is applied in the field of wet vanadium extraction, can solve the problems of reduced vanadium conversion rate of roasting materials, low vanadium leaching rate, uneven mixing, etc., achieves good effect, significant economic benefits, and low vanadium loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

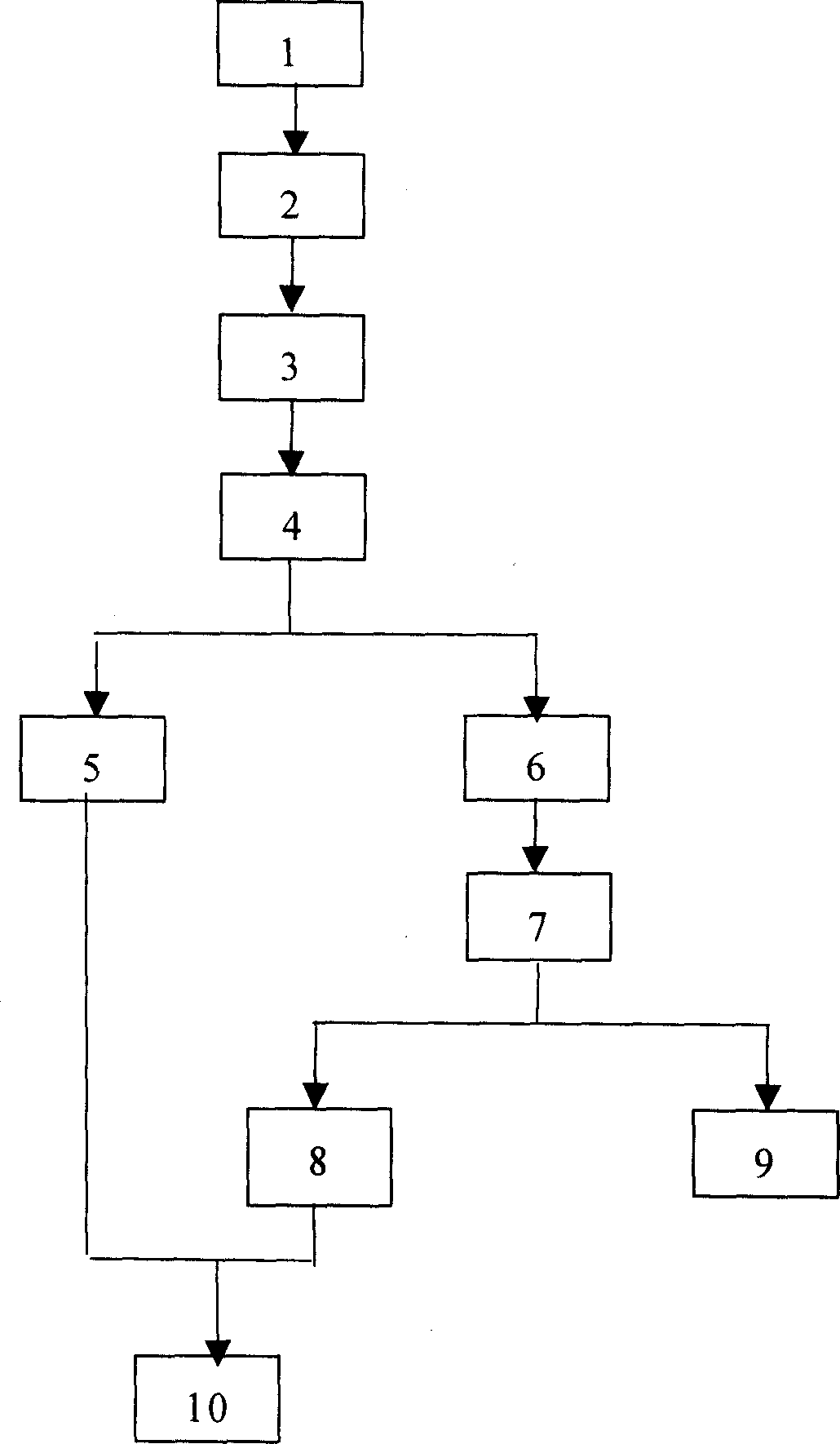

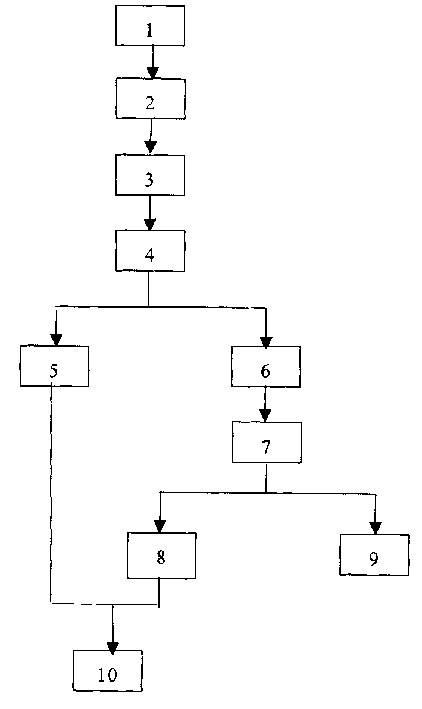

Method used

Image

Examples

Embodiment 1

[0029] Raw materials used, containing [V]35.63g / L, [P]59mg / L, [Fe]28mg / L, [Al]21mg / L, [Si]810mg / L, 50m3 vanadium-containing clinker leach solution with pH 10 Enter the mixing tank, turn on the steam heating at the same time, when the vanadium-containing clinker leachate is sufficient, turn on the compressed air to stir, and quantitatively add the prepared phosphorus removal purifier solution 0.9m 3 (about 80kg), continue heating and stirring to make it fully react, and stir for another 10 minutes when the solution reaches 80±5°C, then add 50 liters of polyacrylamide solution with a concentration of 3g / l, stir for 10 minutes, and mix well Input to the clarification tank to settle, and obtain [V]35.51g / L, [P]<10mg / L, [Fe]<10mg / L, [Al]<10mg / L, [Si]281mg / L purified vanadium liquid , The underflow slag produced by pressure filtration contains 8.27% of ∑V, 6.38% of acid-soluble vanadium, 1.89% of insoluble vanadium, and 2.37% of P.

Embodiment 2

[0031] Raw materials used, containing [V] 27.46g / L, [P] 39mg / L, [Fe] 23mg / L, [Al] 19mg / L, [Si] 785mg / L, pH 9.5 Vanadium-containing clinker leachate 50m 3 Enter the mixing tank, turn on the steam heating at the same time, when the vanadium-containing clinker leachate is sufficient, turn on the compressed air to stir, and quantitatively add the prepared phosphorus removal purifier solution 0.8m 3 (about 71kg), continue to heat and stir to make it fully react, and stir for another 10 minutes when the solution reaches 80±5°C, then add 50 liters of polyacrylamide solution with a concentration of 3g / L, stir for 10 minutes, and mix well Input it into the clarification tank to settle, and obtain [V]27.34g / L, [P]<10mg / L, [Fe]<10mg / L, [Al]<10mg / L, [Si]298mg / L purified vanadium liquid , The underflow slag produced by pressure filtration contains 7.65% of ∑V, 6.03% of acid-soluble vanadium, 1.62% of insoluble vanadium, and 2.24% of P.

Embodiment 3

[0033] Raw materials used, containing [V] 33.50g / L, [P] 61mg / L, [Fe] 25mg / L, [Al] 18mg / L, [Si] 698mg / L, pH 10 vanadium-containing clinker leachate 50m 3 Enter the mixing tank, turn on the steam heating at the same time, when the vanadium-containing clinker leachate is sufficient, turn on the compressed air to stir, and quantitatively add the prepared dephosphorization purifying agent solution 0.85m 3 (about 76kg), continue to heat and stir to make it fully react, and stir for another 10 minutes when the solution reaches 80±5°C, then add 50 liters of polyacrylamide solution with a concentration of 3g / L, stir for 10 minutes, and mix well Input it into the clarification tank to settle, and obtain [V]33.39g / L, [P]<10mg / L, [Fe]<10mg / L, [Al]<10mg / L, [Si]244mg / L purified vanadium liquid , The underflow slag produced by pressure filtration contains 8.81% of ∑V, 6.81% of acid-soluble vanadium, 1.92% of insoluble vanadium, and 3.75% of P.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com