Conductive part for image forming device

A conductive and image technology, applied in the direction of electric recording process applying charge pattern, equipment for electric recording process applying charge pattern, conductive material dispersed in non-conductive inorganic material, etc. Problems such as oxene and environmental dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 8~11

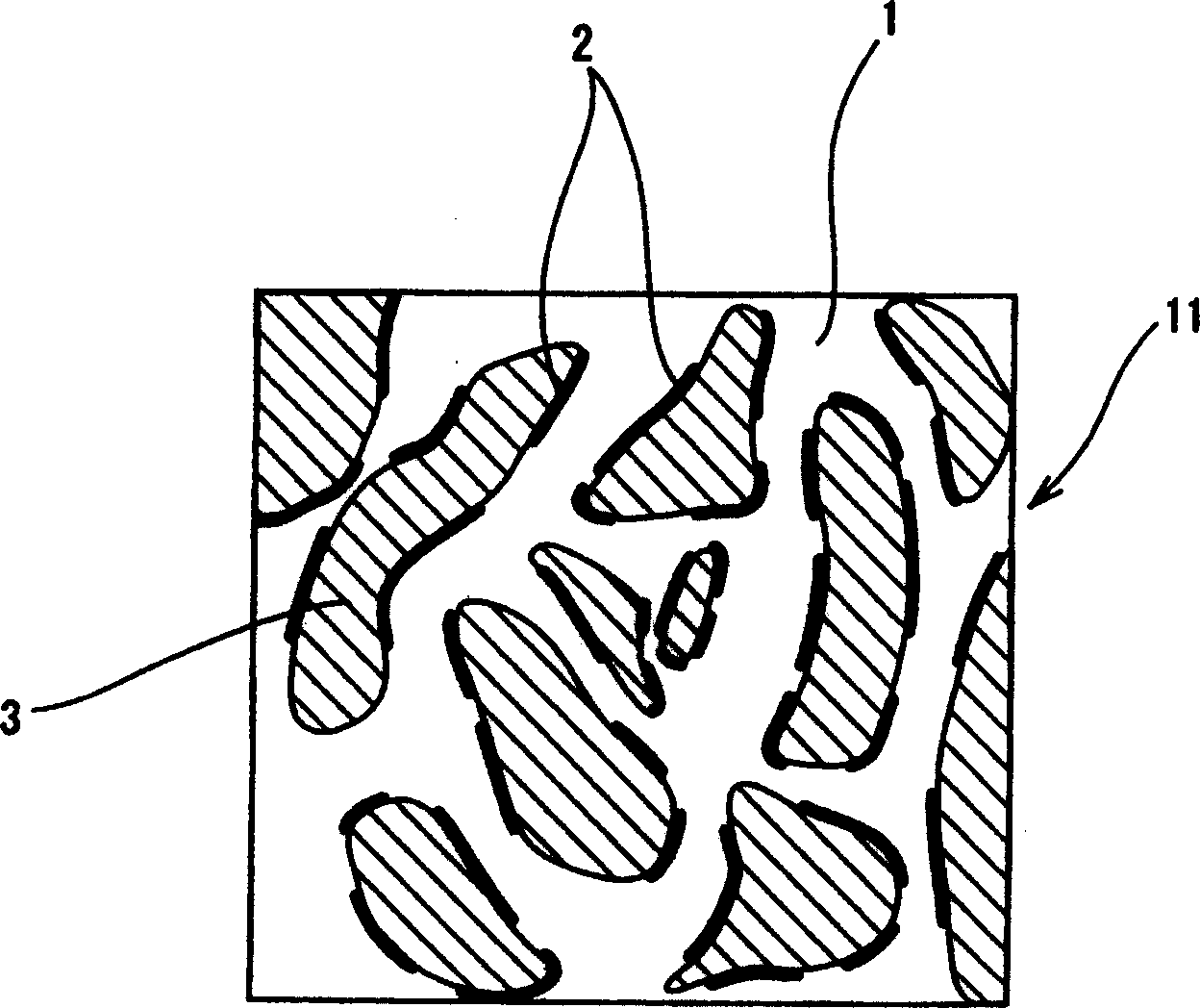

[0211] In Examples 8 to 11, EO-PO-AGE copolymers were used as the polymers constituting the discontinuous phase, and salts 3 to 6, which are salts that can be dissociated into cations and anions, are prevalent in this material, respectively. Salt 3 is potassium bis(trifluoromethanesulfonyl)imide, salt 4 is hexyltrimethylammonium-bis(trifluoromethanesulfonyl)imide, and salt 5 is 1-ethyl-3-methylimidazolium -Bis(trifluoromethanesulfonyl)imide (abbreviated as EMI-TFSI), salt 6 is 1-ethyl-3-methylimidazolium-tetrafluoroborate (abbreviated as EMI-BF4).

[0212] Otherwise, it was the same as Example 2, and a solid roll was made.

[0213] Salt 4 is a quaternary ammonium salt of a trimethyl group (with three methyl groups in R1 to R4) whose cation is represented by Chemical Formula 2, the salt is an imidazolium salt represented by Chemical Formula 2, one of R5 or R6 is a methyl group and the other is a methyl group. is ethyl.

Embodiment 1~11

[0235] The following are related to [Examples 1 to 11] and [Comparative Examples 1 to 10].

[0236] In an environment of 23° C. and a relative humidity of 55%, a constant voltage of 1000 V was continuously applied to the roller for 96 hours in the same state as when the roller resistance value [Ω] was measured. At this time, the values of the roller resistance value R (t=0hr.) immediately after the voltage application and the roller resistance value R (t=96hr.) after the application of the voltage for 96 hours were measured in the same manner as described above, and the continuous energization was conducted using these values. The resistance increase amount at the time: Δlog10R(t=96hr.)[Ω]=log10R(t=96hr.)-log10R(t=0hr.) calculation. Numerical values are shown in Tables 1 to 4. In addition, since the rotational speed of the aluminum drum was 30 rpm and the diameter was 30 mmφ, the linear velocity at the time of rotation was 94 mm / min.

[0237] (compression set)

[0238] ...

Embodiment 12~17

[0288] The following are related to [Examples 12 to 17] and [Comparative Examples 11 to 16].

[0289] In an environment of 23°C and a relative humidity of 55%, in the same state as in the measurement of the fixed volume resistance value, at a certain point in the conductive belt with a thickness of 0.25 mm, a digital ultra High-resistance microcurrent meter R-8240A, a constant voltage of 1000V was applied continuously for 5 hours. At this time, in the same manner as described above, the value of the constant volume resistance value ρV (t=0hr.) of the belt immediately after the voltage application and the value of the constant volume resistance value ρV (t=5hr.) of the belt after the application of the voltage for 5 hours were measured using These values are calculated for the resistance increase amount at the time of continuous energization: Δlog10ρV (t=5-0hr.) [Ω]=log10ρV (t=5hr.)−log10ρV (t=0hr.). Numerical values are shown in Tables 5 to 7.

[0290] (in-plane unevenne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com