Adaptive microtype optical fibre connector

A fiber optic connector and self-adaptive technology, applied in the direction of optical waveguide light guide, optical waveguide coupling, etc., can solve the problems of damage, lack of space, and difficulty in grasping the scale of manual movement of micro-device structures, etc., and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

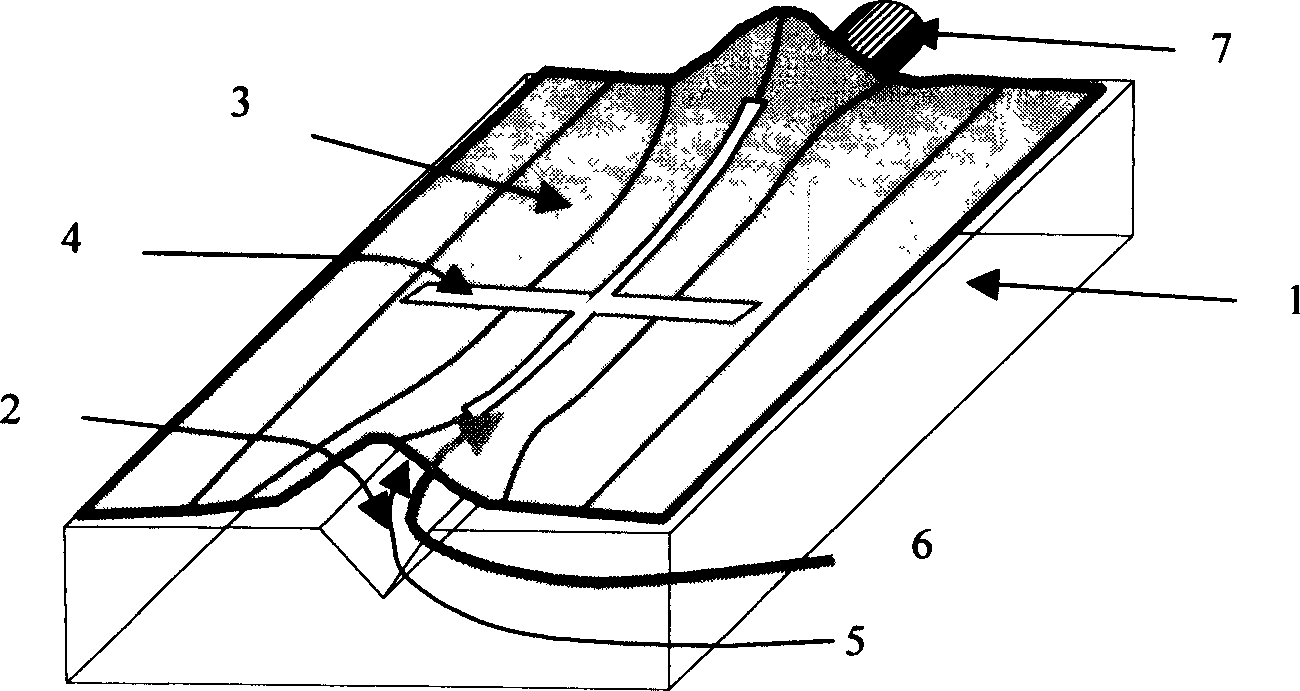

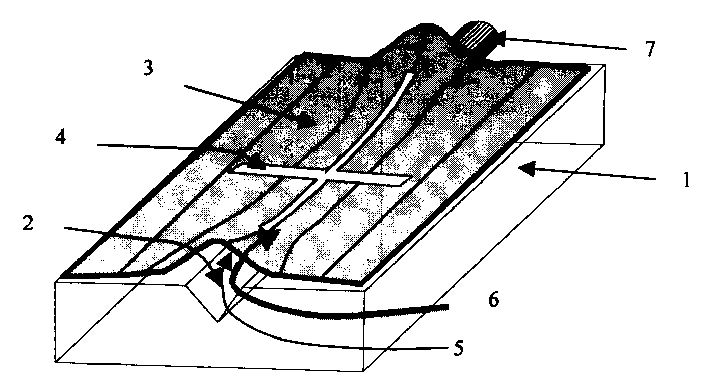

[0024] Using single crystal silicon wafer as the substrate and electrodeposited nickel thin film as the cover material, a typical miniature optical fiber connector was prepared by multi-layer microstructure three-dimensional micromachining technology. The process is as follows:

[0025] Starting from thermally oxidized silicon wafers, first mask photolithography and then chemically etch with buffered hydrofluoric acid to open an etching window for the V-shaped groove 2, and then use 35% KOH to anisotropically etch at 70°C for about 3 hours to form V-groove 2. Fill the formed V-groove with photoresist (such as AZ4630, etc.), cure at low temperature, spin-cut and level off, spin-coat a 30-micron thick glue on the surface, go through photolithography, bake the glue at 90°C, and then spin-coat 5 microns The photoresist is then baked again at 95° C. for 100 minutes to form a semi-tapered photoresist structure that causes the two ends of the cover plate 3 to warp. Then photolithogra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com