Process for purificaton and prodn. of diolefin hydrocarbon stream

A diene, stream technology, applied in raw material containing polymer solvent and has reduced polymerization, separation of butadiene feedstock stream to produce polymer solvent and has reduced polymerization field, can solve the problem of reducing catalyst activity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

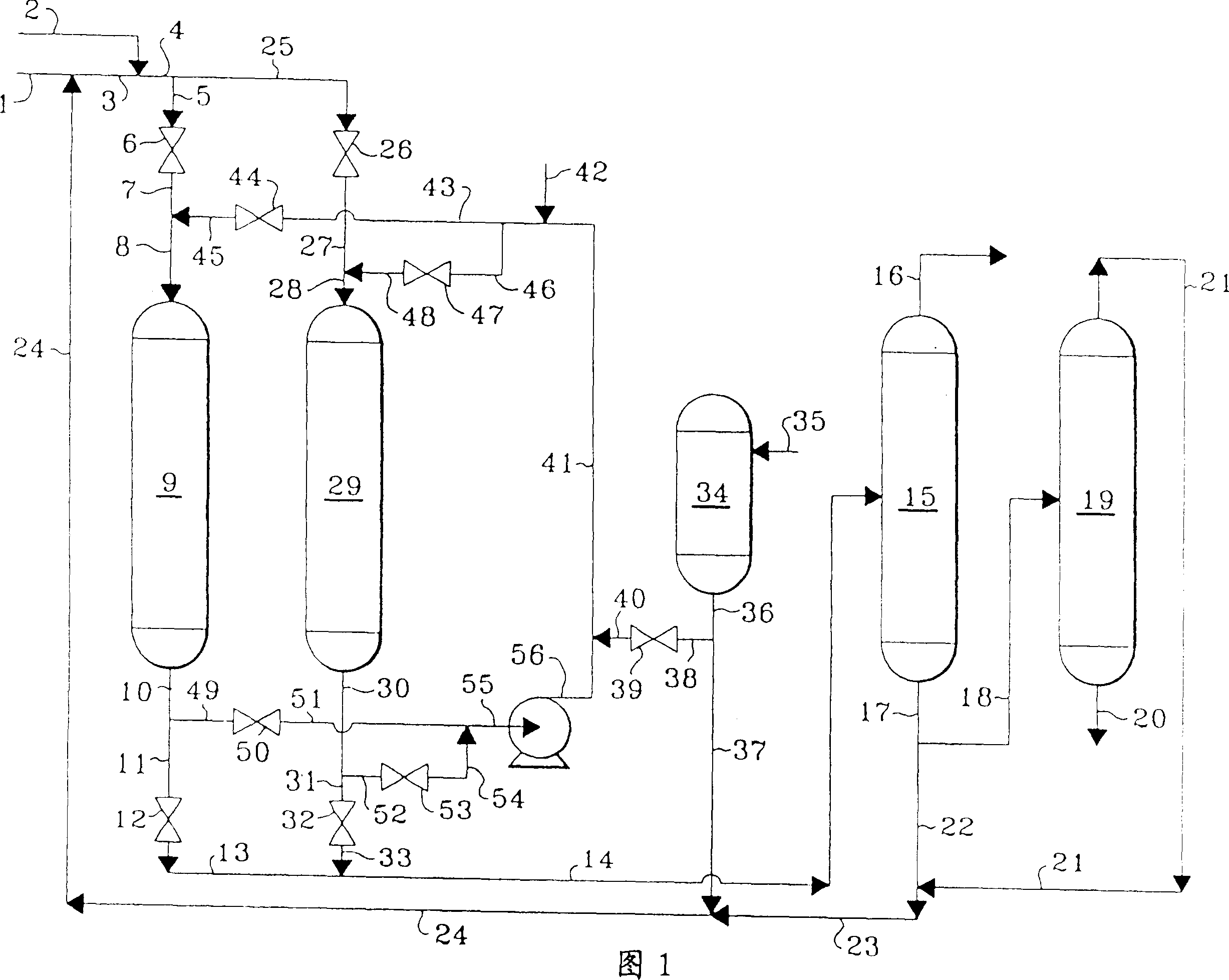

Image

Examples

Embodiment 1

[0026] In a prior art process for the purification of a butadiene stream, fresh feedstock having the characteristics and rates shown in Table 1 was mixed with 20,240 Kg / hr hexane solvent and 10.5 Kg / hr hydrogen and fed into a The selective hydrogenation zone of the selective hydrogenation catalyst. The effluent obtained from the selective hydrogenation zone, which also contains 10.1Kg / hr green oil (green oil) (generated in the selective hydrogenation zone), is fed to the solvent recovery column to generate butadiene whose composition and rate are shown in Table 2 The product stream, while recovering the hexane solvent containing the green oil, and recycling at least a portion of the solvent to the inlet of the selective hydrogenation zone. A small amount of light gas stream containing hydrogen, 1-butene and 1,3-butadiene was produced and recovered at a rate of 57 Kg / hr. A slipstream of recycled hexane solvent containing green oil at a rate of 1610Kg / hr (comprising 1575Kg / hr h...

Embodiment 2

[0028] The process described in Example 1 was repeated with the addition of a step in which the same recycled hexane solvent containing green oil was fed to the viscous stream fractionation zone to produce a 32 Kg of hexane containing 16.1 Kg / hr and 14.1 Kg / hr green oil / hr sticky stream. The remaining 1558.9 Kg / hr hexane was recovered as recycled hexane solvent. Therefore, only 16.1Kg / hr fresh hexane needs to be supplemented. The solvent was replenished at a rate of only 0.001% by weight butadiene feed.

[0029] Table 1 - Feedstock Composition and Rates

[0030] components Rate(Kg / hr)

[0031] Propylene 0.1

[0032] Propylene -

[0033] Propylene 1.0

[0034] 1-butene 81.0

[0035] 1,3-Butadiene 20150

[0036] Butyne 1.6

[0037] Vinyl acetylene 0.4

[0038] Green Oil 4.0

[0039] Residue 2.0

[0040] To...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com