Garbage disposal catalyst with high-temperature water vapor stability

A waste treatment and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, hydrocarbon oil treatment, etc., can solve the problems of complex process procedures, lack of catalysts, high production costs, etc., to save steam consumption, improve heating efficiency, improve The effect of carbonization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

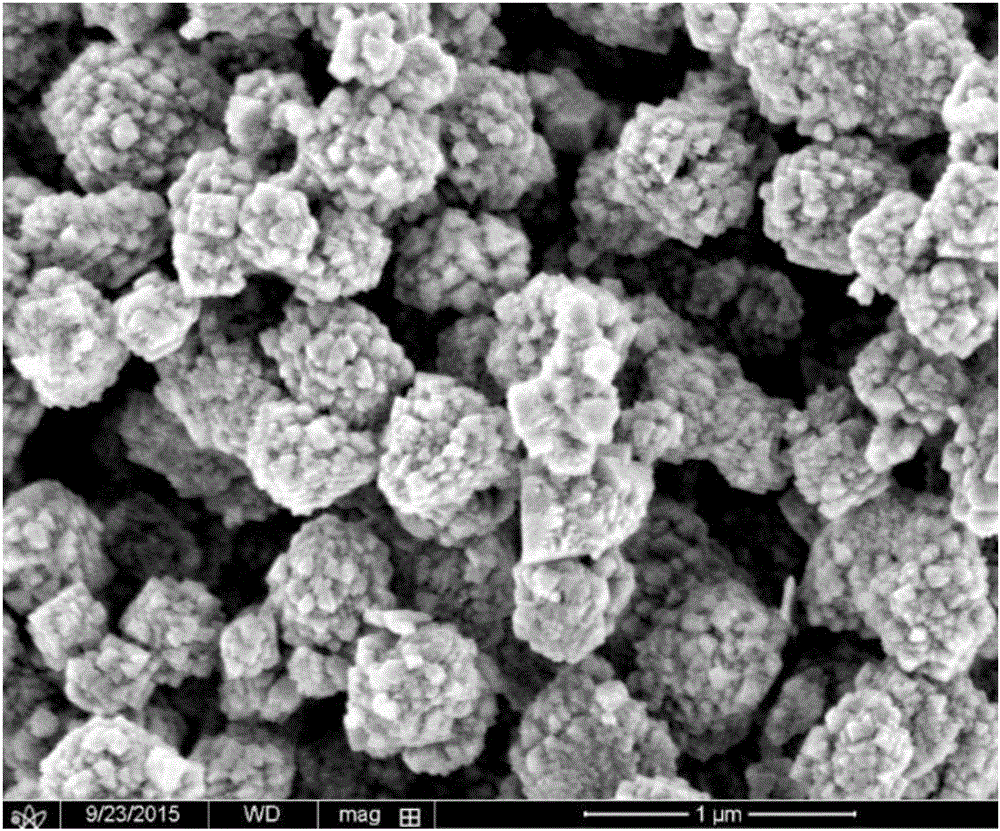

[0063] The hydrogenation catalyst is prepared as follows: weigh a certain amount of Co(NO 3 ) 2 ·6H 2 O, add citric acid and deionized water to dissolve, make a solution with a concentration of 3.0mol / L, weigh a certain amount of zeolite beta and put it into a reaction vessel, pour the prepared solution into the reaction vessel, and place it with Heat in the constant temperature heating oil bath device of the stirrer, stir at 60-120°C for 1h-10h, then put it in a drying oven and dry at 100°C for 2h, then place the obtained catalyst precursor in a muffle furnace at 350°C Calcined for 3h, then switched to CS 2 In a mixed gas atmosphere of saturated steam and hydrogen, vulcanize at 60°C for 1.0 hour to prepare CoS / β zeolite; (2) Weigh a certain amount of precursor salt such as Ni(NO 3 ) 2 , Cu(NO 3 ) 2 , Pd(NO 3 ) 2 and citric acid, add deionized water to dissolve, stir evenly, and make a solution with a concentration of 0.5mol / L, weigh a certain amount of the CoS / β zeoli...

Embodiment 2

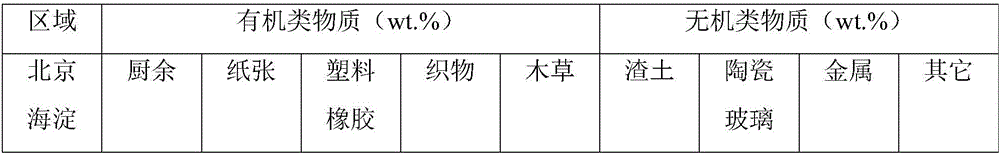

[0065] Domestic waste from the Wuluju Waste Compression and Transfer Station in Haidian District, Beijing was selected. The composition of the waste was tested and shown in Table 1 below:

[0066] Table 1: Composition of MSW

[0067]

[0068]

[0069] The above-mentioned garbage is subjected to high-temperature distillation carbonization through the following steps: loading the garbage into the garbage transportation device; passing the garbage transportation device through the high-temperature distillation carbonization device; taking out the gas stream from the upper part of the high-temperature distillation carbonization device; passing the gas stream in gaseous form Catalyst bed; condensing and separating the effluent from the catalyst bed to obtain liquid combustibles and water; obtaining charcoal from the waste transport unit passing through the high-temperature distillation carbonization unit. The high-temperature distillation carbonization device is heated by hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com