Mn-zn ferrite containing less than 50 mol% fe2o3

A ferrite, V2O5 technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problem that resistance is not very effective, it is difficult to Mn-Zn ferrite at the same time, and it can meet the needs of soft magnetism and resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

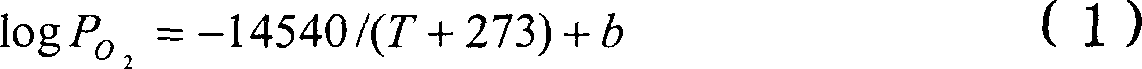

[0027] Eleven different test samples, including 4 comparative samples, were made with the composition shown in Table 1. Raw material powder Fe 2 o 3 , ZnO and MnO were mixed, stirred with an attritor, calcined at 850° C. in air for 2 hours, and ground with an attritor for 1 hour to obtain a mixture powder. Then, the TiO 2 , SnO 2 , CaO, SiO 2 , CuO, Nb 2 o 5 and V 2 o 5 The powder is properly added to the mixture powder to adjust the components, then the adjusted mixture powder is stirred for 1 hour with a grinder, added polyvinyl alcohol to granulate, and pressed into a ring core (green body) under a pressure of 80MPa, each The outer diameter is 25mm, the inner diameter is 15mm, and the height is 5mm. The green body was sintered at 1200° C. for 2 hours and then cooled in the furnace. The atmosphere therein was controlled by filling nitrogen into the furnace to obtain the oxygen partial pressure at which the constant b in formula (1) was set at 9 o’clock. Inventive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com