Liquid level stabilizing device in micro-analysis chip liquid pool and method of use thereof

A technology with stable liquid level and liquid storage tank, which is applied in the direction of microbial measurement/inspection, analytical materials, measuring devices, etc., to achieve stable liquid level, realize hydraulic pressure, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

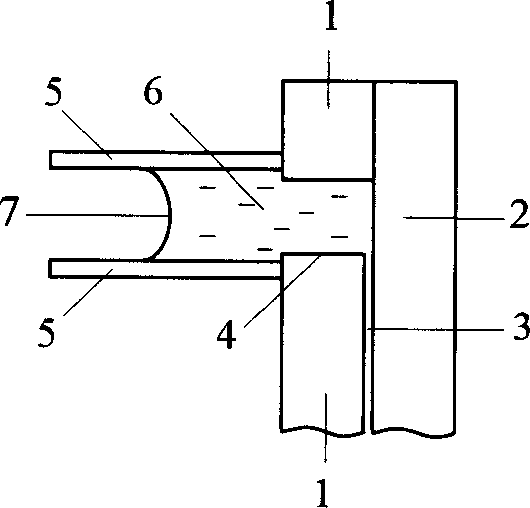

[0030] figure 1 . is a side sectional view of a preferred embodiment 1 according to the present invention. The microfluidic chip is composed of upper (1) and lower (2) two pieces. The upper (1) and lower (2) two pieces are sealed by bonding method, and the microchannel (3) is processed on the upper piece (1). . Holes are punched on the upper sheet (1) to form connecting channels (4). The chip is placed upright, and the horizontal channel (5) tube is directly fixed on the surface of the upper chip (1) around the opening of the connecting channel (4) to form a liquid storage pool. The liquid (6) in the liquid storage tank communicates with the microchannel (3), and the phase interface between the liquid (6) and the external atmosphere—the vertical liquid surface (7) is arc-shaped.

Embodiment 2

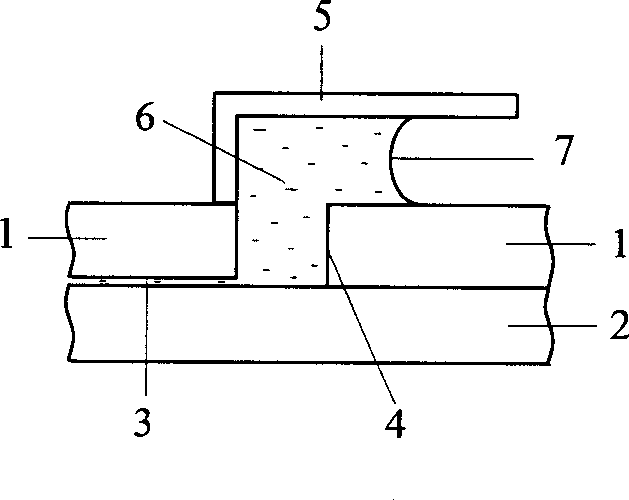

[0032] figure 2 . is a side sectional view of yet another preferred embodiment 2 of the present invention. The micro analysis and control chip is composed of upper (1) and lower (2). The bonding method is used to realize the sealing of the upper (1) and lower (2) pieces. Microchannels (3) are processed on the upper sheet (1). Holes are punched on the upper sheet (1) to form connecting channels (4). The chip is placed horizontally, and the horizontal channel (5) tube is directly fixed on the surface of the upper chip (1) around the opening of the connecting channel (4) to form a liquid storage pool. The liquid (6) in the liquid storage tank communicates with the microchannel (3), and the phase interface between the liquid (6) and the external atmosphere—the vertical liquid surface (7) is arc-shaped.

Embodiment 3

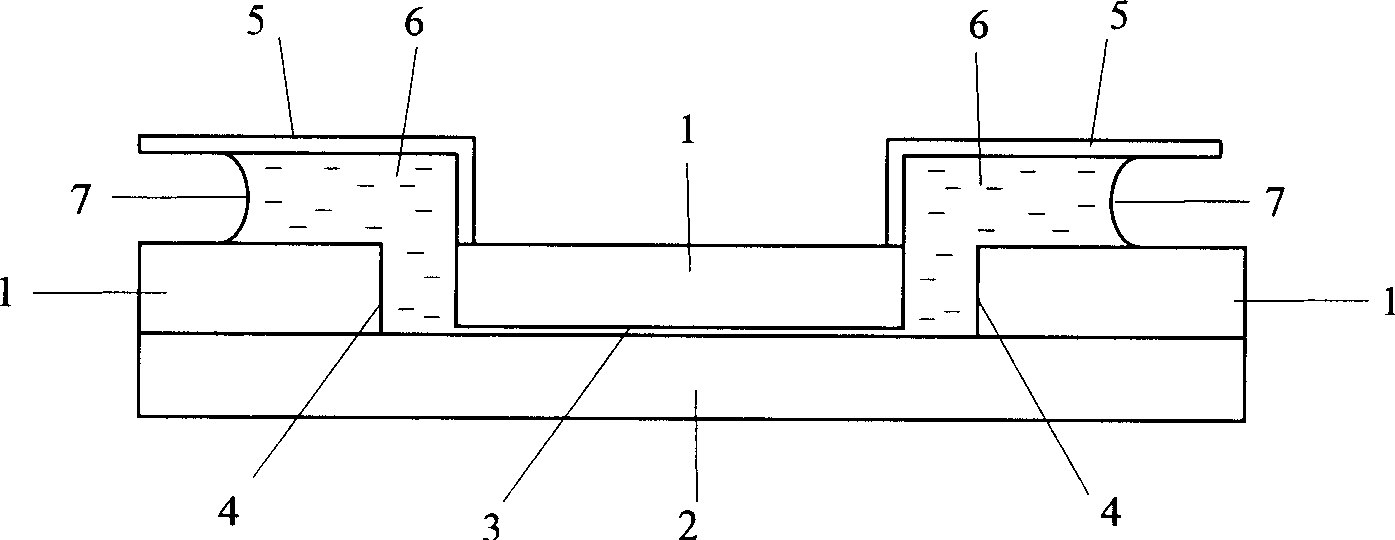

[0034] image 3. is a side cross-sectional view of a microfluidic chip for overall system liquid level stabilization according to a preferred embodiment of the present invention. The micro-analysis chip is composed of upper (1) and lower (2). The bonding method is used to realize the sealing of the upper (1) and lower (2) pieces. Microchannels (3) are processed on the upper sheet (1). A hole is punched at both ends of the microchannel (3) on the upper sheet (1) to form a connecting channel (4). The chip is placed horizontally, directly on the surface of the upper chip (1), and a horizontal channel (5) tube is fixed around the opening of the connecting channel (4) to form a liquid storage pool. The liquid (6) in the liquid storage tank communicates with the microchannel (3), and the phase interface between the liquid (6) and the external atmosphere—the vertical liquid surface (7) is arc-shaped. The two horizontal channels are on the same level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com