MPC500 process type electric car multi-energy power assembly control device

A technology for electric vehicles and powertrains, applied in battery/fuel cell control devices, electric vehicles, control devices, etc., can solve the problem of no technical relevance of control devices, achieve optimal scheduling and management control, and improve integration. The effect of improving the degree of portability and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The implementation example of the electric vehicle multi-energy powertrain control device based on the MPC500 series microprocessor proposed by the present invention is the research and development of the fuel cell electric vehicle multi-energy powertrain control system THECU-2002 type test prototype, below in conjunction with the accompanying drawings and Implementation examples are described in detail.

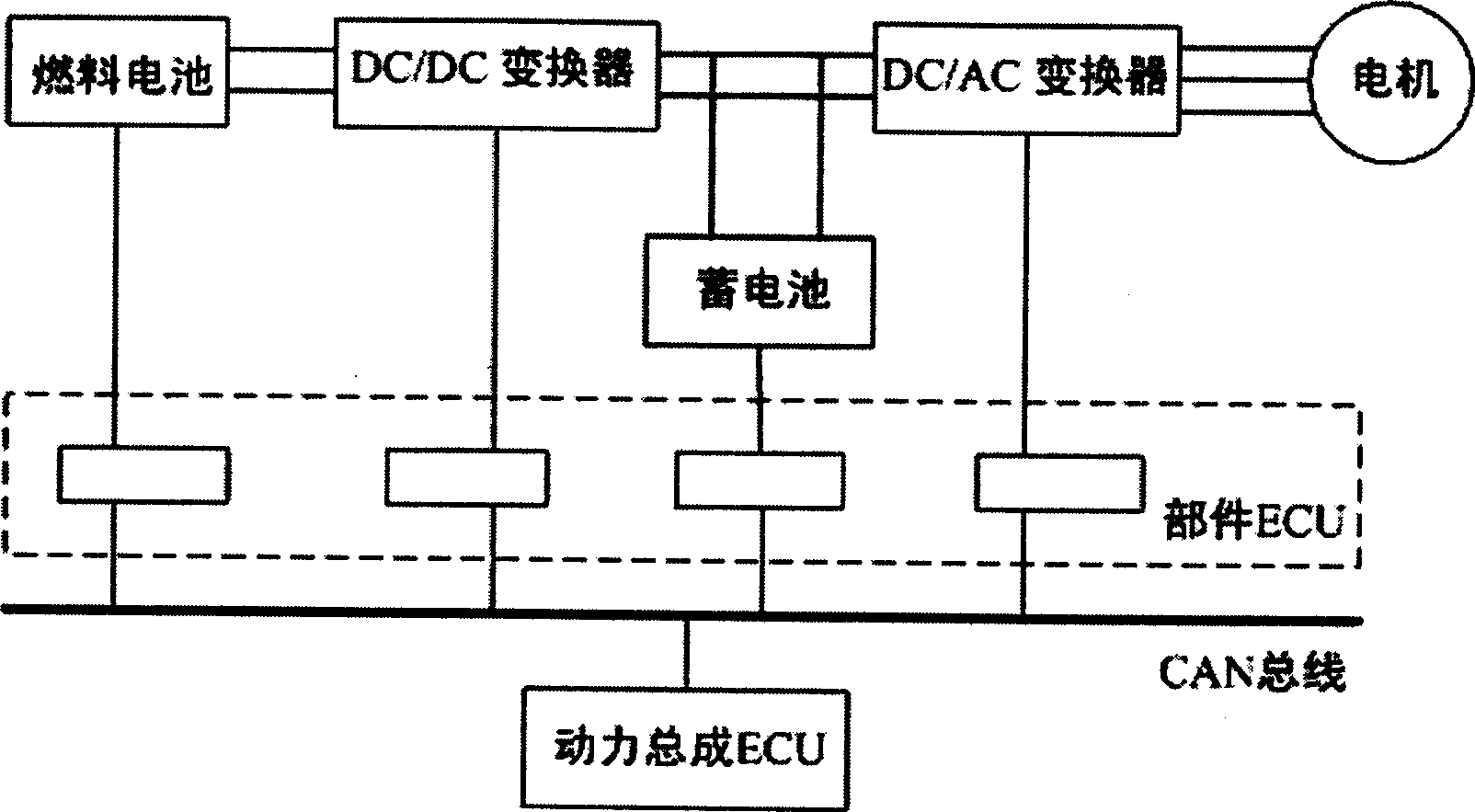

[0064] Fuel cell electric vehicle multi-energy powertrain system architecture such as figure 1 shown. The power system is composed of motor and controller, fuel cell, storage battery, DC / DC converter, etc., and is physically connected through an electrical bus. Communication between powertrain ECU and component ECU is realized through CAN (Controller Area Network) bus. The invention relates to a powertrain electronic control unit (Powertrain ECU).

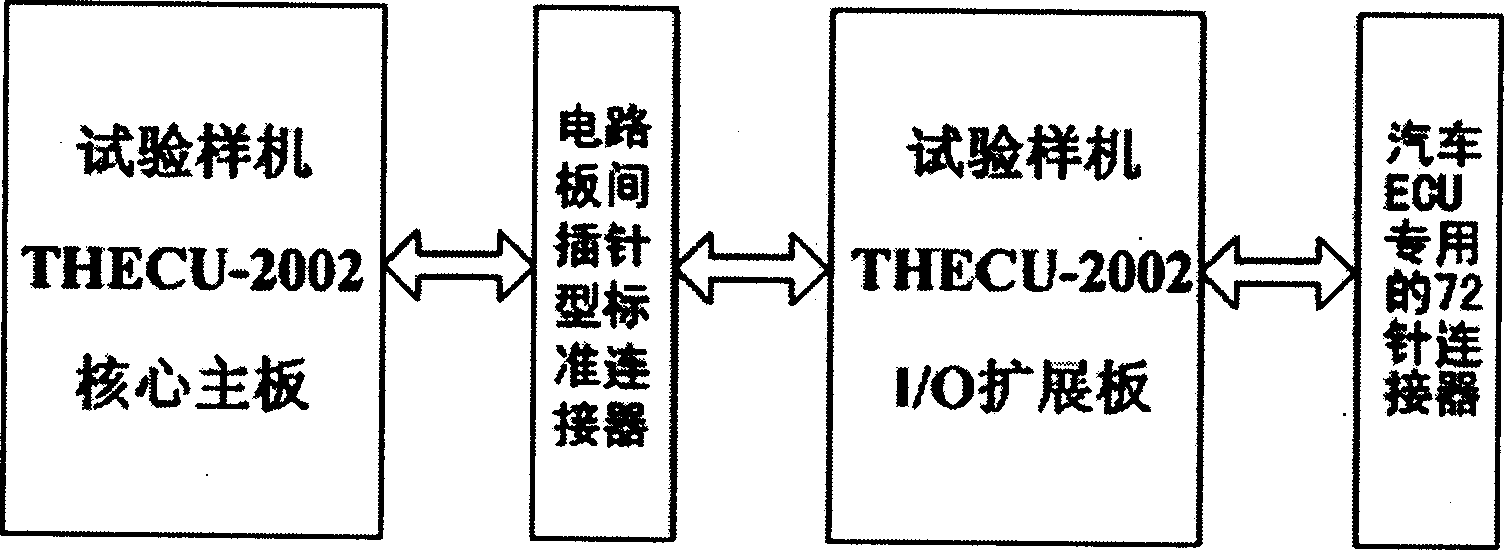

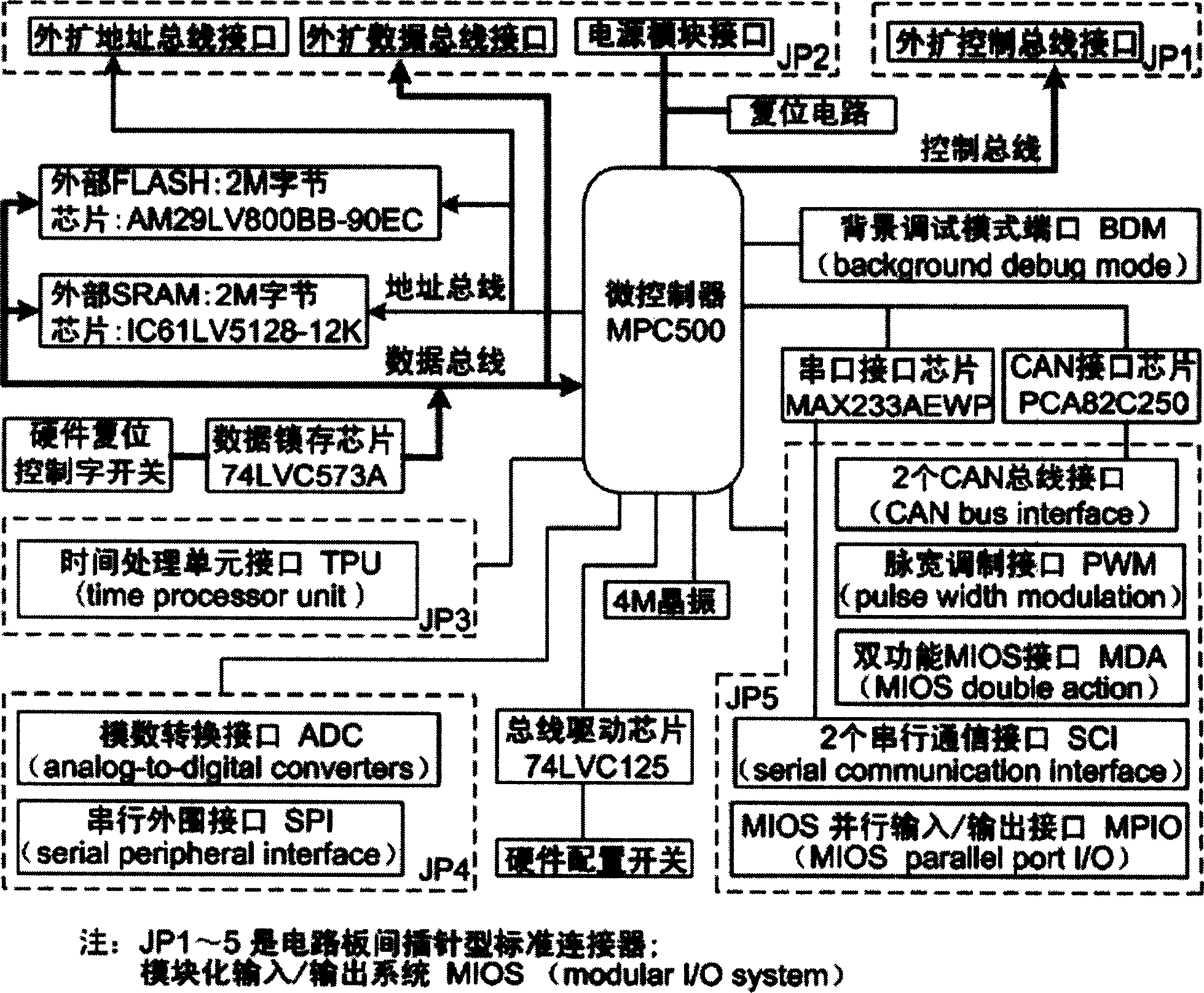

[0065] The fuel cell electric vehicle multi-energy powertrain control system THECU-2002 test prototype takes the MPC5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com