GC high-temperature high-pressure sample directly-sampling method and equipment

A gas chromatography, high temperature and high pressure technology, applied in the field of gas chromatography sampling, can solve the problems of loss of dissolved gas, complicated operation, large error, etc., and achieve the effect of quantitative accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

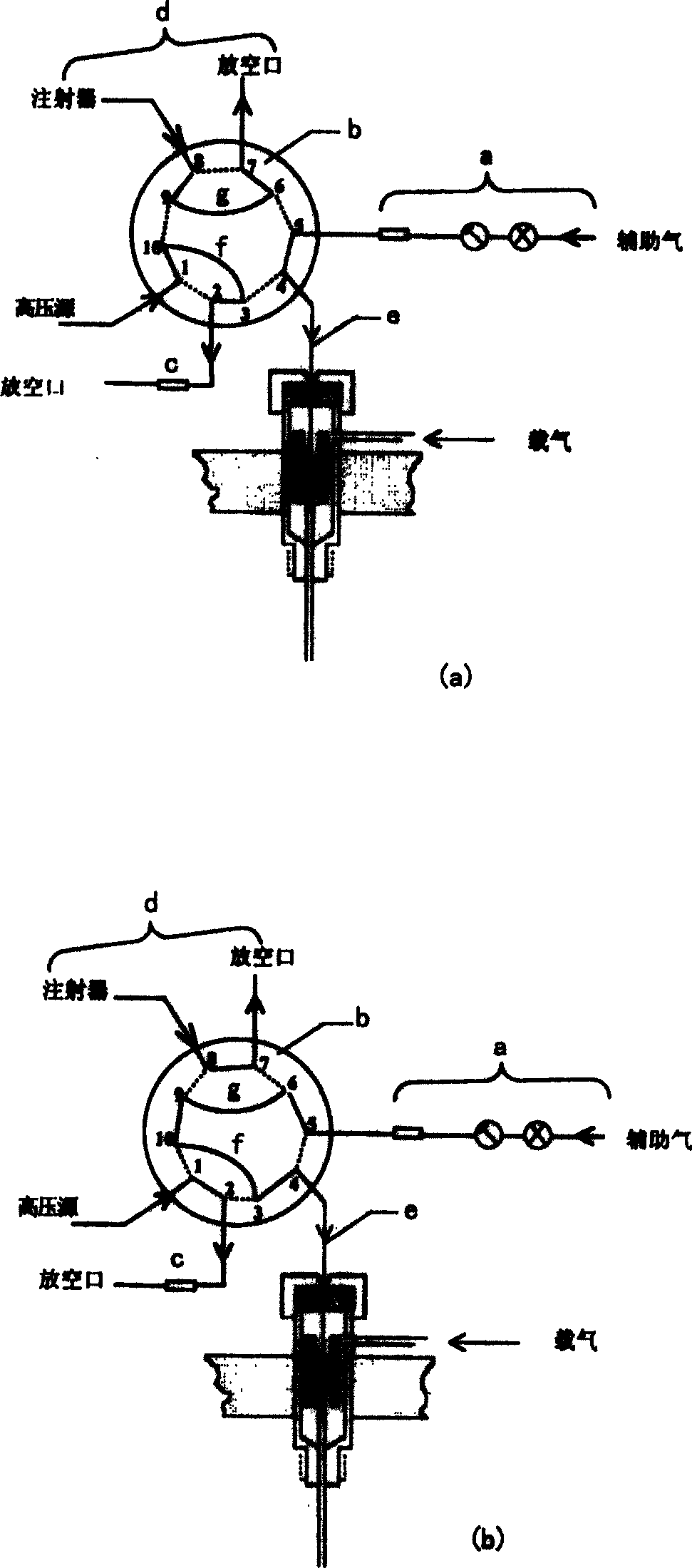

Method used

Image

Examples

Embodiment 1

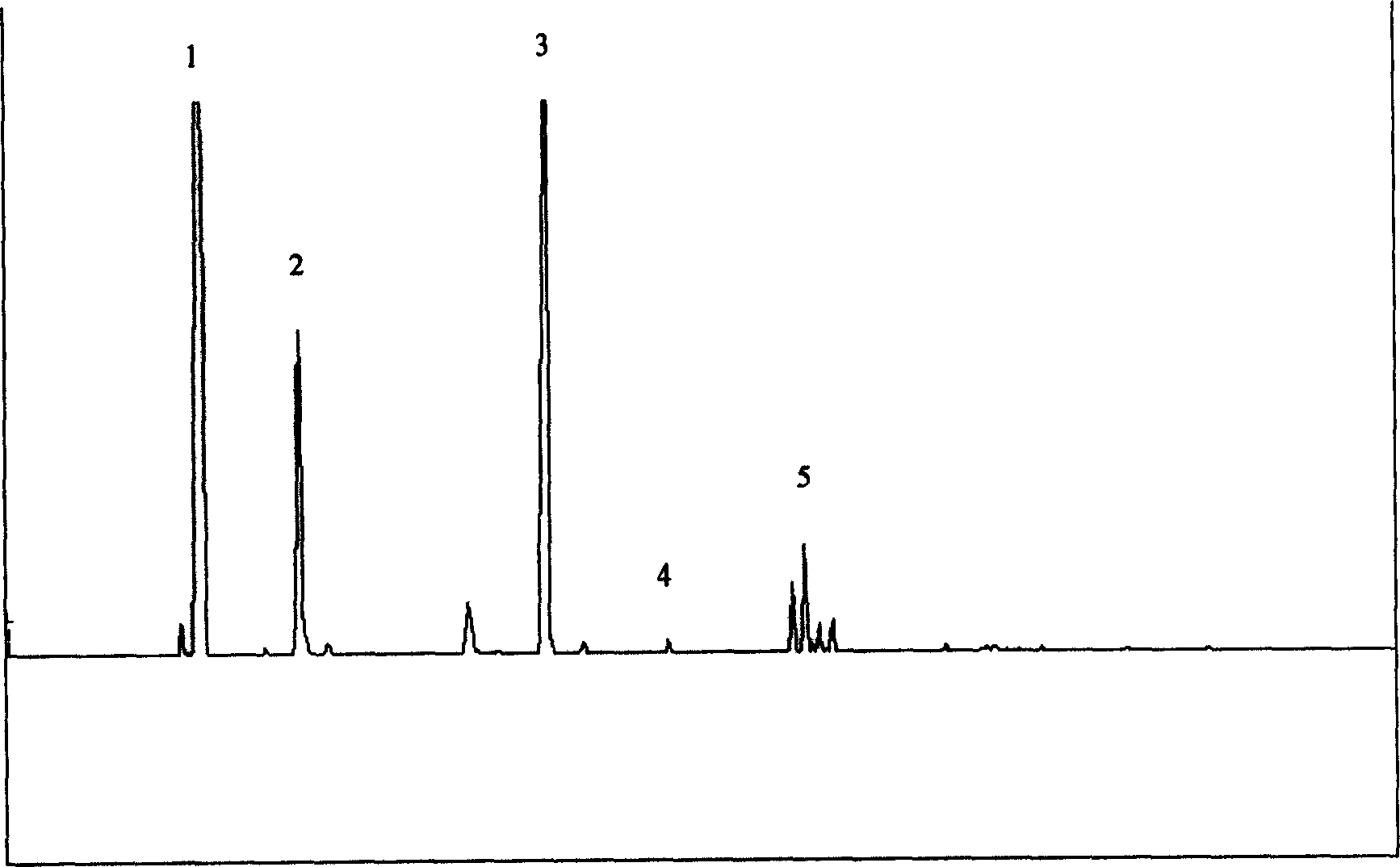

[0023] Example 1: Determination of composition of liquid phase product of hexene-1 by valve injection under normal pressure

[0024] The auxiliary gas flow is controlled at 4mL / min by a steady flow valve, VALCO ten-way liquid phase valve, the sample quantitative tube is a 25μm×120mm quartz capillary, 0.1μL, the eluting tube is a 100μm×120mm quartz capillary, 0.5μL, and the eluent is For n-pentane, the capillary sampling tube is a 50 μm × 25 cm quartz capillary tube, split injection, the split ratio is 40:1, the analytical column is 30 m × 0.53 mm inner diameter × 1.5 μm large diameter SE-54 quartz capillary column, and the detector is FID , The valve switching time is instantaneous switching. The chromatogram is shown in Figure 2.

Embodiment 2

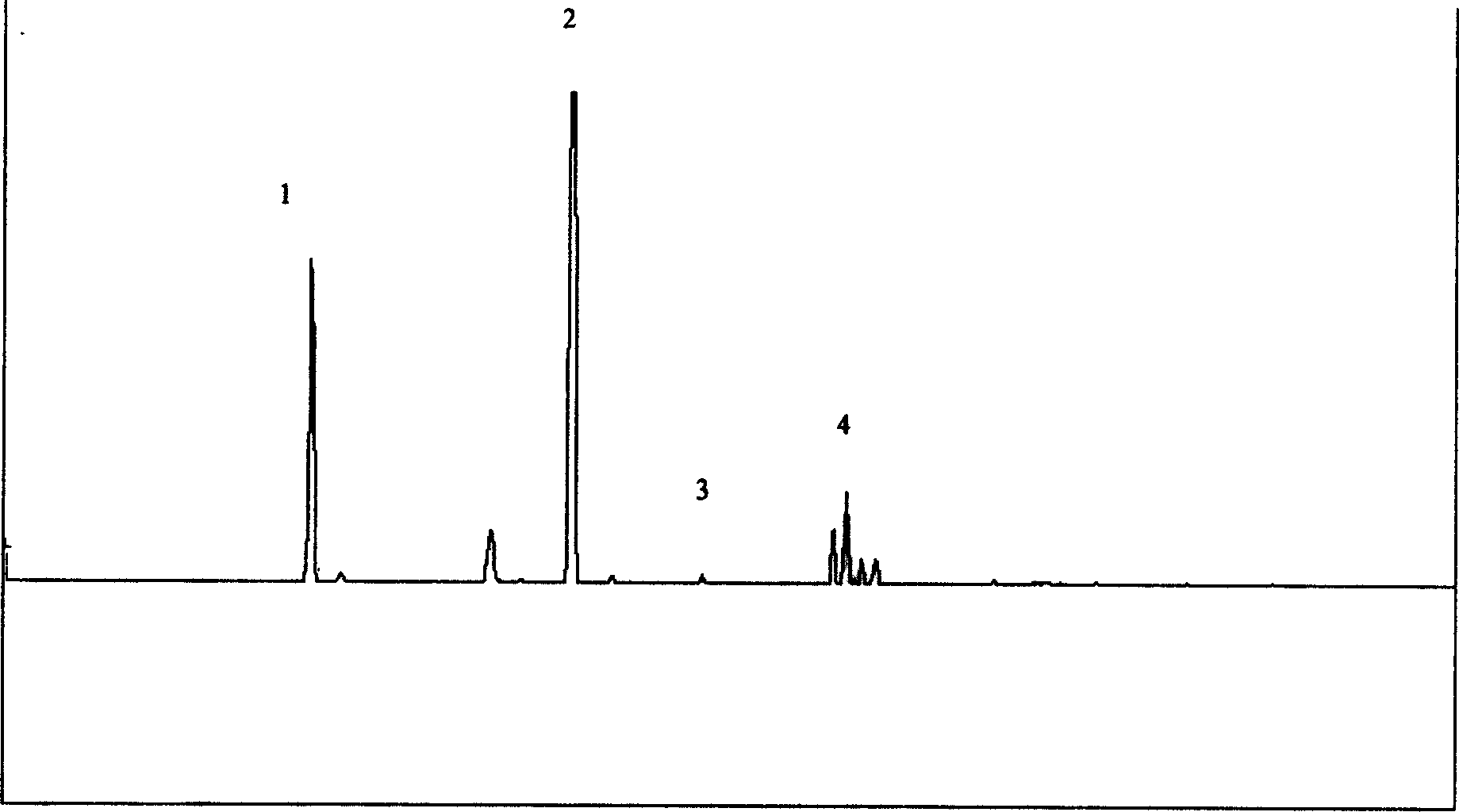

[0025] Embodiment 2: Determination of the composition of the liquid phase product of hexene-1 injected into a micro-syringe under normal pressure

[0026] A micro-syringe was used to inject samples, the injection volume was 0.1 μL, and the split injection was performed with a split ratio of 40:1. The analytical column was a 30m×0.53mm×1.5μm large-diameter SE-54 quartz capillary column, and the detector was an FID. The chromatogram is shown in Figure 3.

Embodiment 3

[0027] Example 3: Determination of liquid phase composition of hexene-1 reaction under 50kg pressure by online valve collection and injection

[0028] The auxiliary gas flow rate is controlled at 4mL / min by a steady flow valve, VALCO ten-way liquid phase valve, the sample quantitative tube adopts a 25μm×120mm quartz capillary tube, 0.1μL, the damping tube adopts a 10m×25μm quartz capillary tube, and the elution solvent quantitative tube adopts a 100μm× 120mm quartz capillary, 0.5μL, n-pentane is used as eluent, 50μm×25cm quartz capillary is used as capillary sampling tube, split injection, split ratio 40:1, analytical column is 30m×0.53mm×1.5μm large diameter SE -54 quartz capillary column, the detector is FID, and the valve switching time is instantaneous. The chromatogram is shown in Figure 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com