Method for producing flour noodles

A processing method and technology of noodle thread, applied in application, food preparation, food science and other directions, can solve the problems of affecting the health of consumers, difficult storage and transportation, poor appearance and toughness, etc., and achieve convenient storage and transportation, easy packaging and transportation, The effect of low break rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The surface thread processing method comprises the steps of:

[0042] 1. Provide a raw material, including 75% flour, 20% water, and 5% salt; a mixing bucket.

[0043] 2. Fully stir the raw materials in the mixing bucket and make a dough.

[0044] 3. The dough is drawn into thin strips with a molding machine and cut off according to the required length, bundled into bundles to obtain semi-finished noodles and preliminarily dried, with a moisture content of 5%.

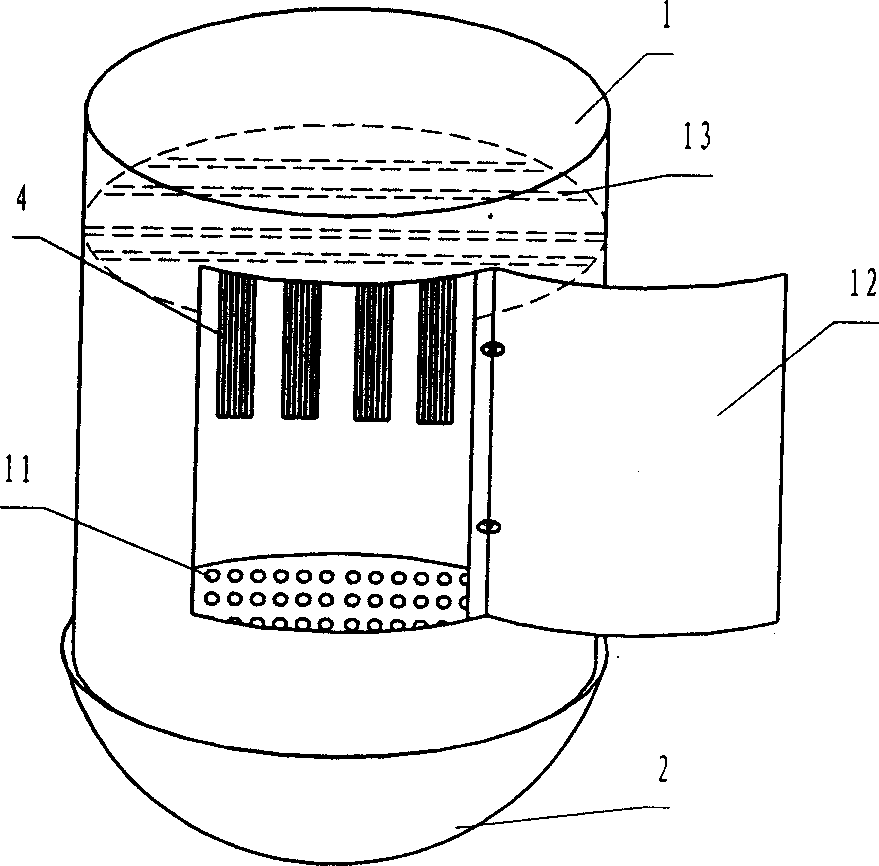

[0045] 4, provide a kind of sealable airtight box 1 and steamer 2 that have air vent 11 at the bottom (see figure 1 ), the hanging pole 13 of the noodle thread is fixed in the sealed box 1, and the sealed box 1 is placed on the steamer 2.

[0046] 5. Put the semi-finished noodle thread 4 into the sealed box 1 and hang it up, and seal the box door 12.

[0047] 6. Add water into the steamer 2, heat the steamer 2 with fire, and raise the heating temperature of the sealed box 1 to between 50-100° C. After heating...

Embodiment 2

[0052] The surface thread processing method comprises the steps of:

[0053] In the raw materials, flour is 50%, water is 45%, salt is 5%, and the moisture content of semi-finished noodles is 40%.

[0054] The heating temperature of the sealed box is 120-200° C., and the heating time is 5 hours.

[0055] The rest of the process steps in this embodiment are the same as in Embodiment 1.

Embodiment 3

[0057] The surface thread processing method comprises the steps of:

[0058] 1. Provide a raw material, including 65% flour, 30% water, and 5% salt; a mixing bucket.

[0059] 2. Fully stir the raw materials in the mixing bucket and make a dough.

[0060] 3. The dough is hand-drawn into thin strips and cut off according to the required length, bundled into bundles to obtain semi-finished noodles and preliminarily dried, with a moisture content of 25%.

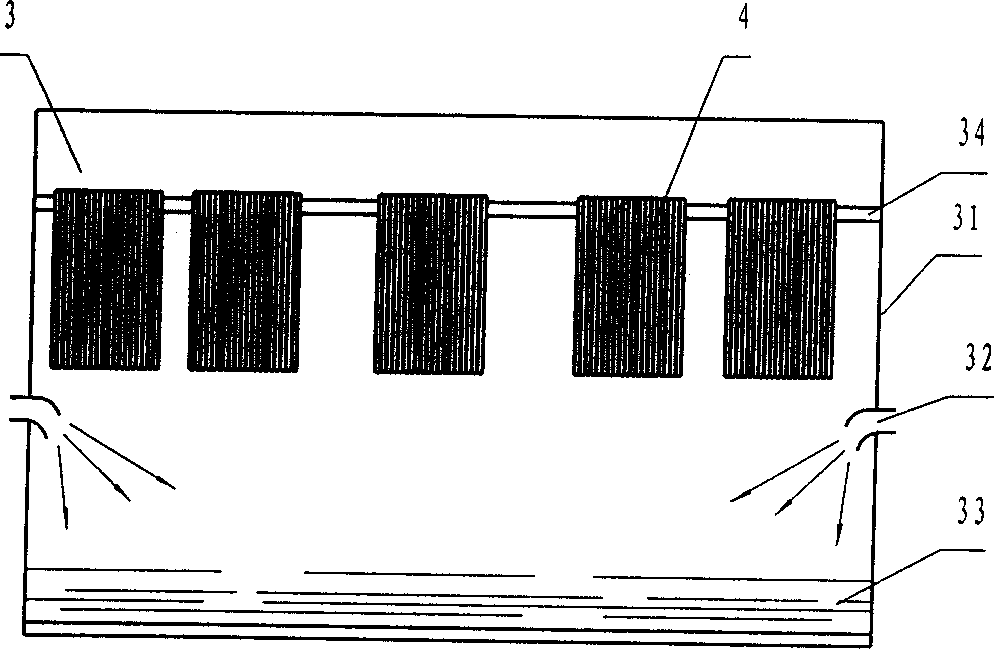

[0061] 4. A kind of sealable noodle steamer 3 is provided, which comprises a steam box 31, the side wall of the steam box 31 has a hot steam inlet 32, the bottom of the steam box 31 has a water storage tank 33, and the side wall of the steam box 31 is also fixed with a The hanging rod 34 of the noodle thread, while the steam box 31 has a door that can be sealed. (See the schematic figure 2 )

[0062] 5. Send the semi-finished noodle thread 4 into the inner cavity of the noodle steamer 3, hang it on the hanging pole 34, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com