Self-damaged and degraded disposable medical injecting apparatus and its manufacturing process

A manufacturing method and disposable technology, which can be used in hypodermic injection devices and other directions, can solve problems such as life-threatening, polluting the environment, endangering people's health, etc., and achieve the effect of increasing or decreasing the degradation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

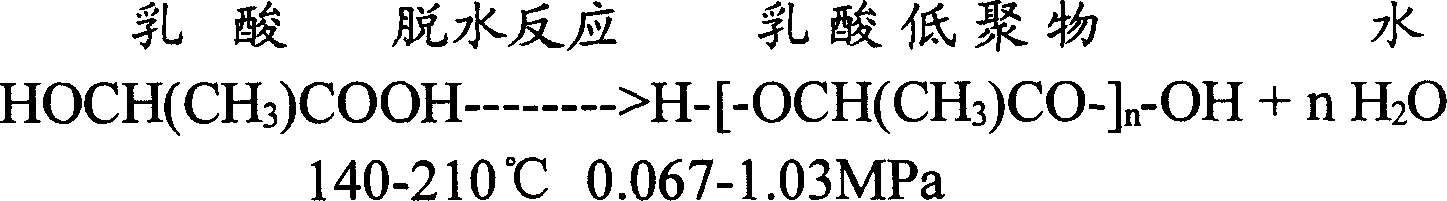

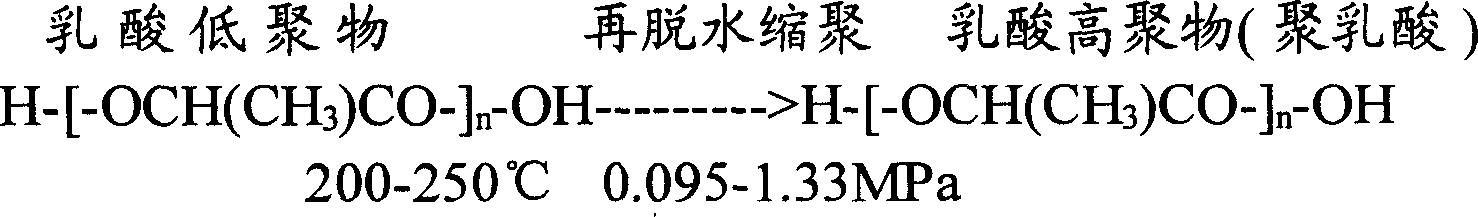

Method used

Image

Examples

Embodiment Construction

[0043] The process of producing disposable self-degradable medical injection equipment and other medical supplies with plant straw as raw material is:

[0044] (1) Raw material pretreatment and saccharification: first clean the plant straw, cut it into pieces with a cutting machine and grind it into a slurry, then add an appropriate amount of water to the air-lift fermenter, and then put the ground plant straw The slurry flows into the fermenter according to the weight ratio of 36-49%, and then add enough water in the weight ratio. After adjusting the pH value of the tank liquid to 6.4, the tank temperature is slowly raised to 100°C, and the tank temperature is lowered after 8-20 minutes. Drop to 70°C, flow in 2-5% cellulase to destroy the crude tissue fiber of the straw, and make the straw slurry preliminary saccharification, after 20-40min the initial saccharification is completed, flow in 0.5-3% saccharification enzyme for further saccharification 20- 40min, make its stalk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com