Two-way two-tube positive excitation converter topology

A technology of forward converter and topology, which is applied in the field of dual-circuit and dual-tube forward converter topology, which can solve the problems of bridge arm direct connection and low reliability, and achieve low switching loss, high reliability, and reduced volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

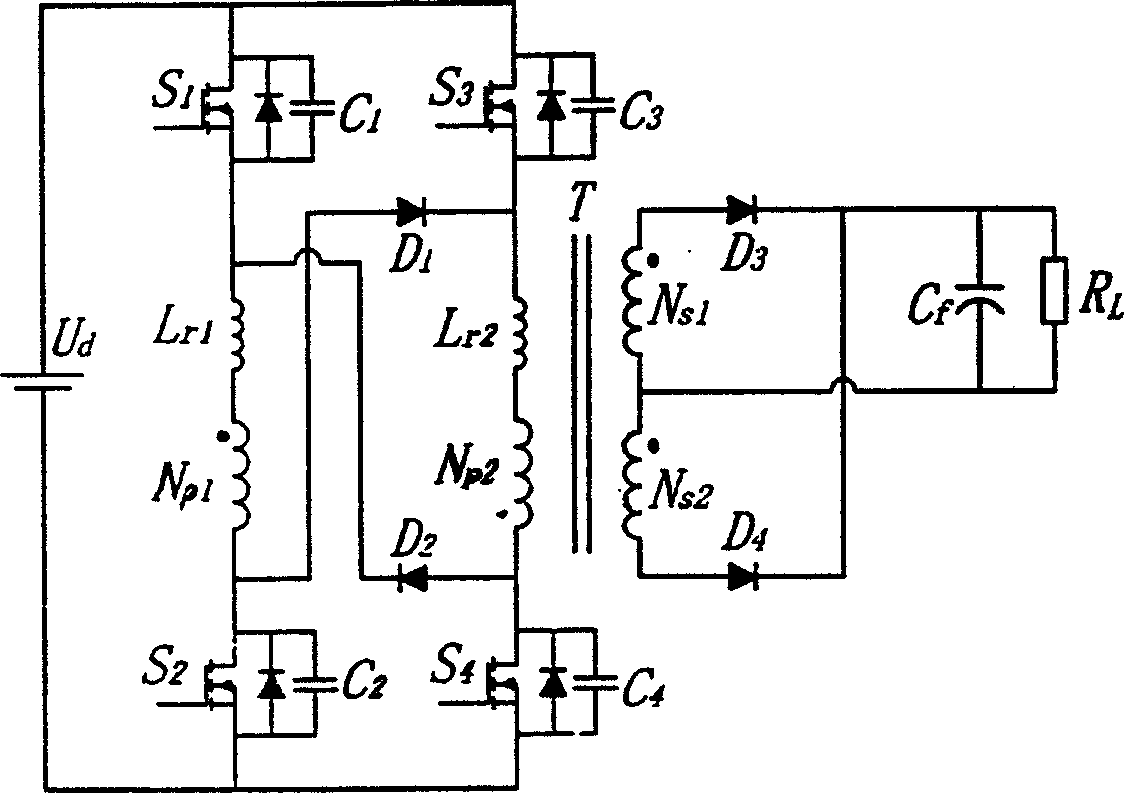

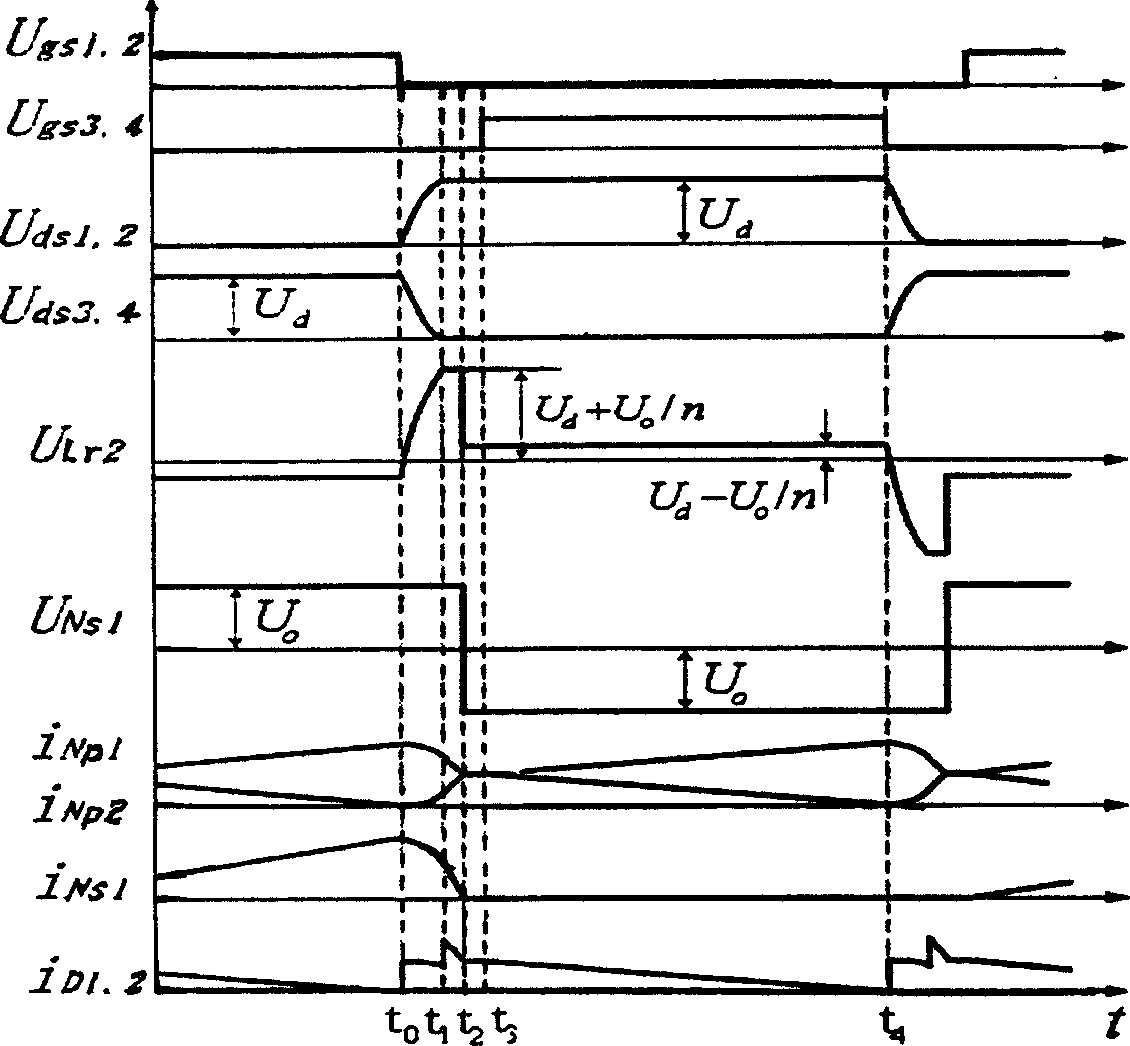

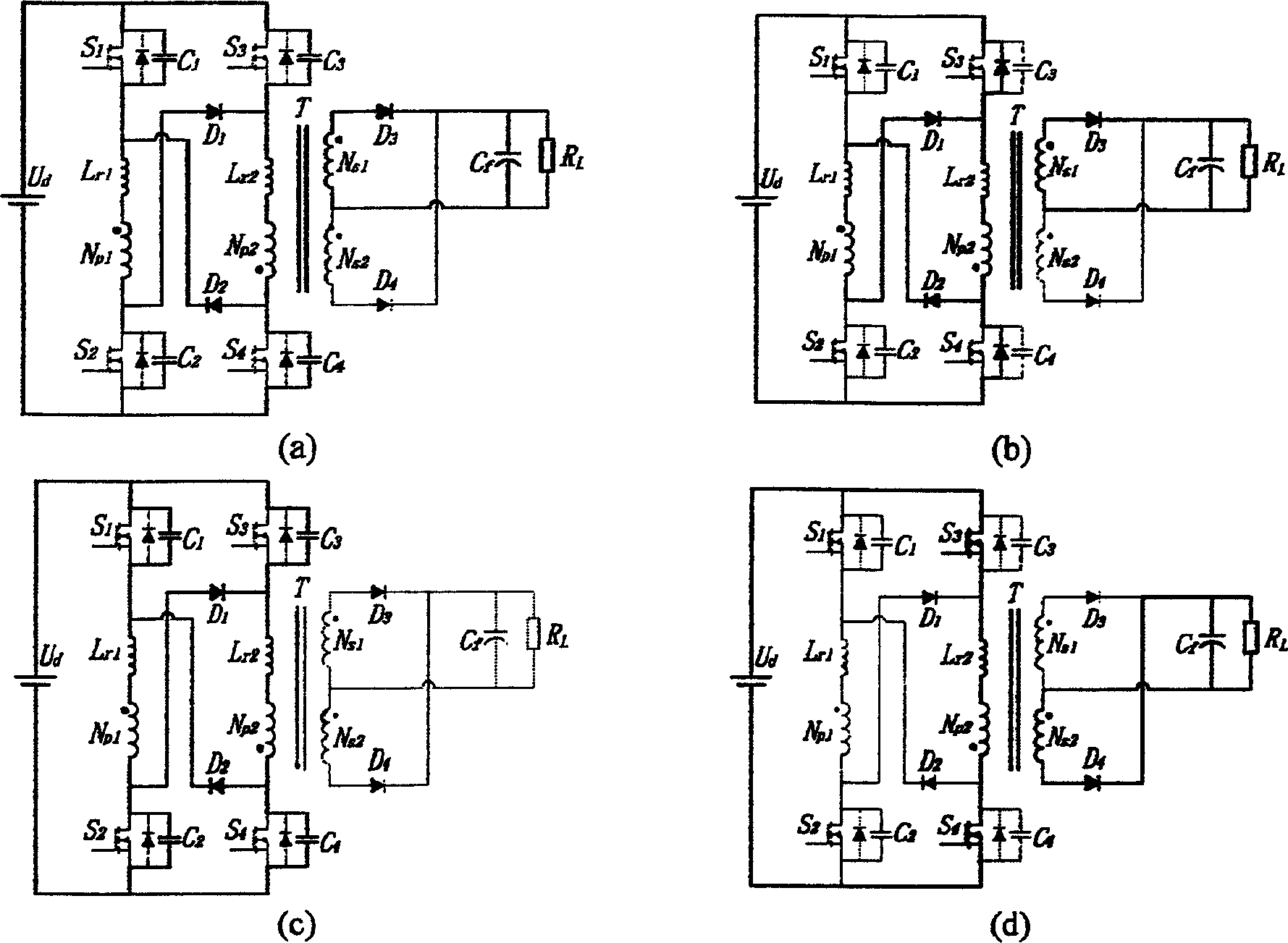

[0019] Specific embodiments of the present invention will be described based on the above-mentioned drawings. Depend on figure 1 It can be seen that the composition of the circuit of the present invention is that the first power switch tube S 1 , inductance L r1 , Main power transformer T primary winding N p1 , the second power switch tube S 2 sequentially connected in series to form a series structure circuit; the third power switch tube S 3 , inductance L r2 , Main power transformer T primary winding N p2 , the fourth power switch tube S 4 In turn, they are connected in series to form another series structure circuit, and the two series structure circuits are connected in parallel to the power supply U at the same time. d ends. clamping diode D 1 Forwardly connected to the second power switch tube S of the first series structure circuit 2 The anode and the third power switch tube S of the second series structure circuit 3 The negative pole of the clamping diode D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com