Fish flour and production method thereof

A fish noodle and flour technology, which is applied to dough processing, dough forming machinery or equipment, and baking, etc., can solve the problems of difficulty in large-scale production of fish noodles, long drying time, easy oxidation of fat, etc. The effect of increasing the rate, improving the surface finish, and improving the color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

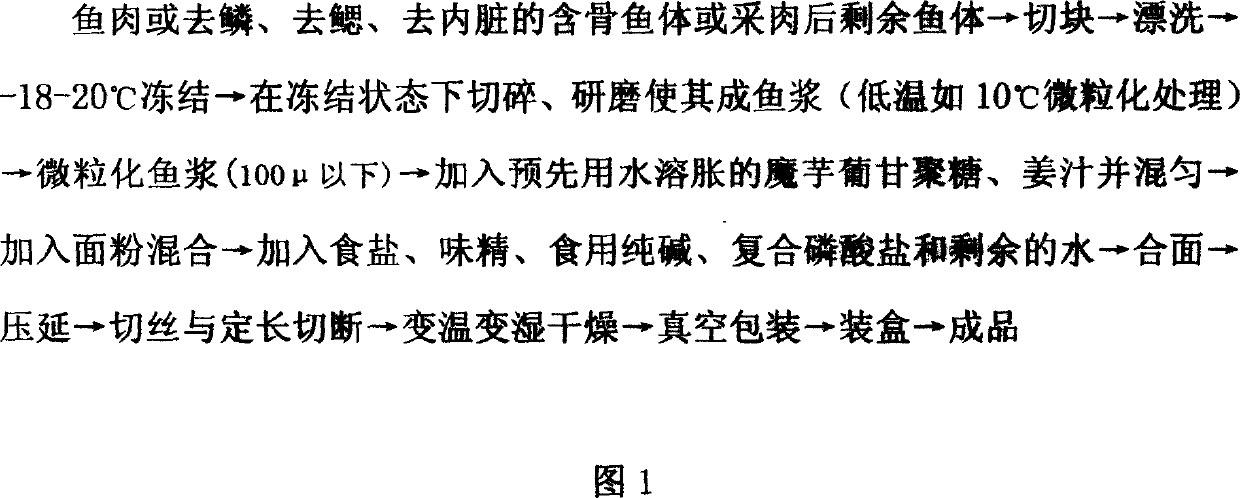

Method used

Image

Examples

Embodiment 1

[0041] Cut 15kg of bone-containing fish body without scales, gills, and viscera or the remaining bone-containing fish body after meat harvesting into small pieces, rinse with tap water to remove blood, drain, freeze at -20°C, and then chop machine, grinder, and bone grinder to make fish paste with a particle diameter of less than 100 μm, add 0.1kg konjac glucomannan (swelled with 2L water in advance), and mix well with 2.0kg ginger juice, set aside; put 100kg flour (high-gluten flour or special flour for noodles) is poured into the noodle joint cylinder of the noodle joint machine, and the above-mentioned mixture is added under stirring, and stirred; finally, 1.0kg salt, 0.1kg edible soda ash, 0.10kg compound phosphate (the compound phosphoric acid salt) Salt is mixed according to the ratio of sodium pyrophosphate: sodium tripolyphosphate 1:1), 0.05kg monosodium glutamate is dissolved in 16L water, added to the above mixture and mixed well, after standing for 30min, calendering...

Embodiment 2

[0043] Cut 30kg of bone-containing fish with scales, gills, viscera or meat into small pieces, rinse with tap water to remove blood, drain and freeze at -20°C, then pass through a chopper and mince Machine, bone grinder to make fish paste with particle diameter below 100μm, add 0.5kg konjac glucomannan (swelled with 6L water in advance), 2.0kg ginger juice (or add white vinegar, white pepper or peppercorns to ginger juice Spices) and mix well, set aside; Pour 100kg of flour (such as special flour for noodles or high-gluten flour) into the noodle joint tank of the noodle machine, add the above mixture under stirring, stir; finally add 1.5kg of salt, 0.15kg Edible soda ash, 0.20kg compound phosphate (prepared according to the method of Example 1), 0.1kg monosodium glutamate were dissolved in 5L water, added to the above mixture and mixed evenly, after standing for 30min, compound calendering was carried out, and calendering became 1.0-1.5mm thick Cut the noodles into strips with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com