Digestion tolerant starch and its preparation method and uses

A technology of anti-digestible starch and starch, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, fermentation, etc., can solve problems that have not been reported before, and achieve industrial production, low development costs, and good social and economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

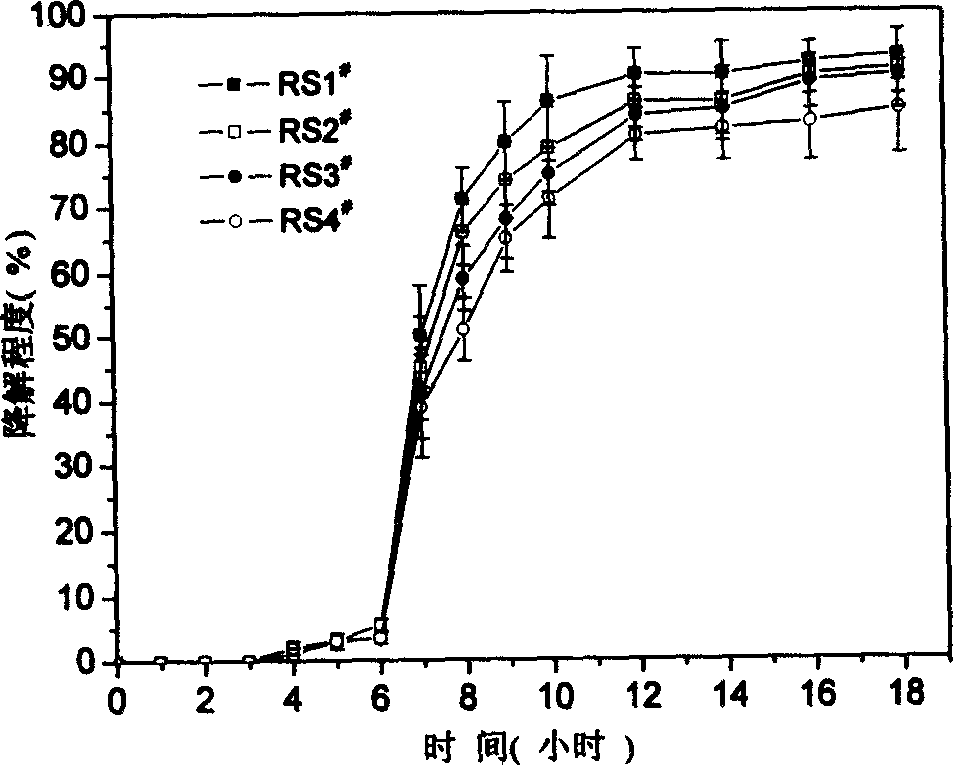

Embodiment 1

[0027] Add 185 grams of water to 815 grams of cornstarch (moisture content is 14.2%) in the mixer, make the material moisture content reach 30%, fully mix; Heat to 90 ℃ in airtight state, constantly stir and keep 30min, the material After cooling down to room temperature in the mixer, take it out, use 5000U / g starch heat-resistant α-amylase at pH 6.0, temperature 100°C for 0.5h, then use 300U / g starch at pH 4.0, temperature 50°C The glucoamylase was fully enzymatically hydrolyzed for 1h; the enzymolyzed product was centrifuged, washed, filtered, dried, and crushed to obtain resistant starch RS1 # .

Embodiment 2

[0029] Add 26.3 grams of water to 500 grams of high-chain corn starch (moisture content is 15.8%) in the mixer to make the material moisture content reach 20%, fully mix and seal for 24 hours, put into 4520PST high-temperature pressure reaction kettle (PARR company in the United States) During the process, adjust the temperature to 120°C, control the pressure at 0.7MPa, and keep the reaction conditions stable for 2 hours. After the material is cooled to room temperature in the mixer, it is taken out and dried in an electric constant temperature blast drying oven at 50°C to obtain anti-digestion Starch RS2 # .

Embodiment 3

[0031] Add 89.6 grams of water to 600 grams of mung bean starch (moisture content is 16.1%) in mixer, make material moisture content reach 27%, fully mix and seal and place 24h, put into 4520PST high-temperature pressure reaction kettle (U.S. PARR company), Adjust the temperature to 110°C, control the pressure at 1MPa, and keep the reaction conditions stable for 1 hour. After the material is cooled to room temperature in the mixer, take it out, and use 8000U / g starch heat-resistant α-amylase at pH 6.0 and temperature 100°C Under the action of 0.5h, then fully enzymolyzed with 300U / g starch glucoamylase at pH 4.5 and temperature 60°C for 1h; the enzymolyzed product was centrifuged, washed, dried and pulverized in an electric heating constant temperature blast drying oven at 50°C Resistant starch RS3 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com