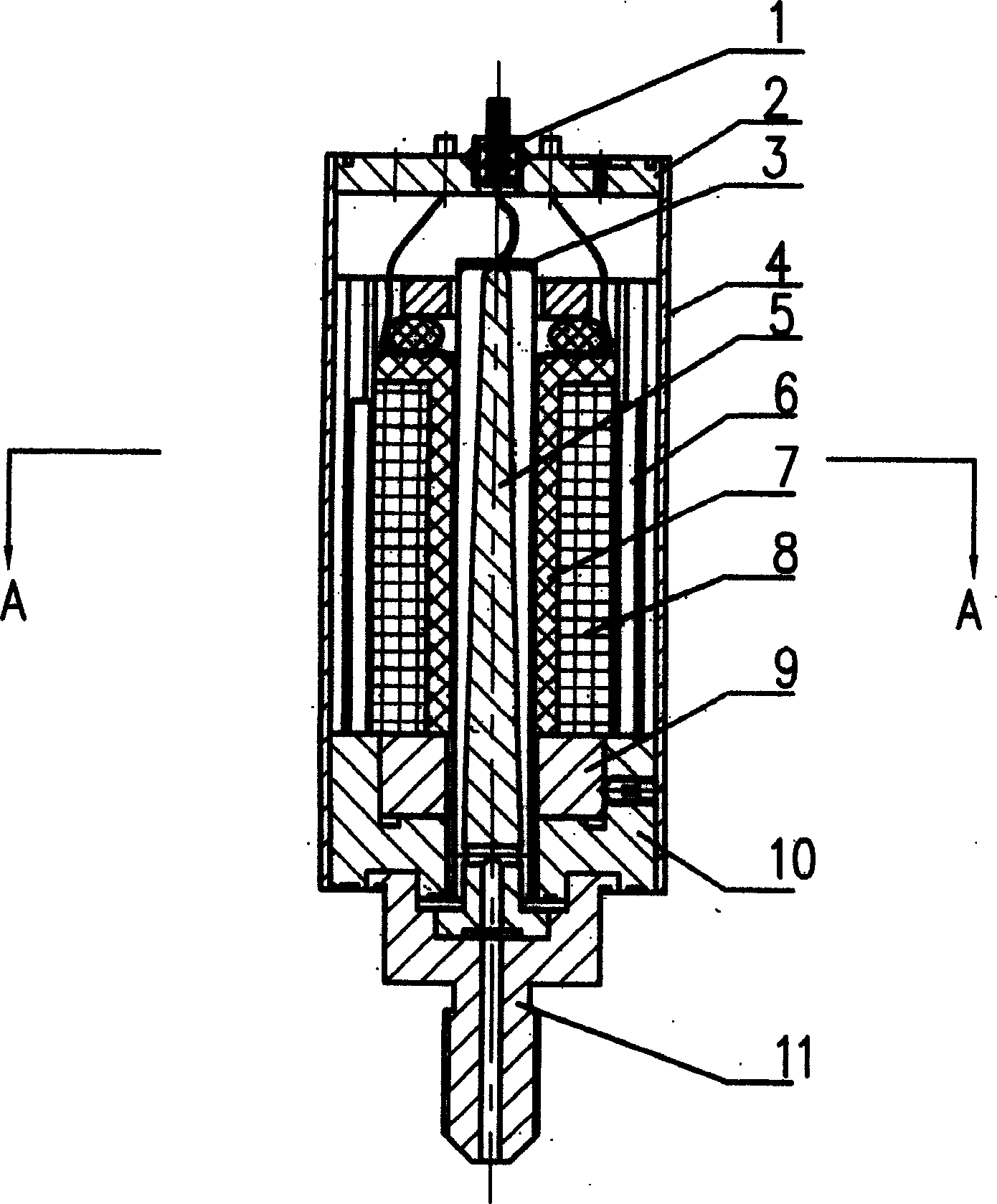

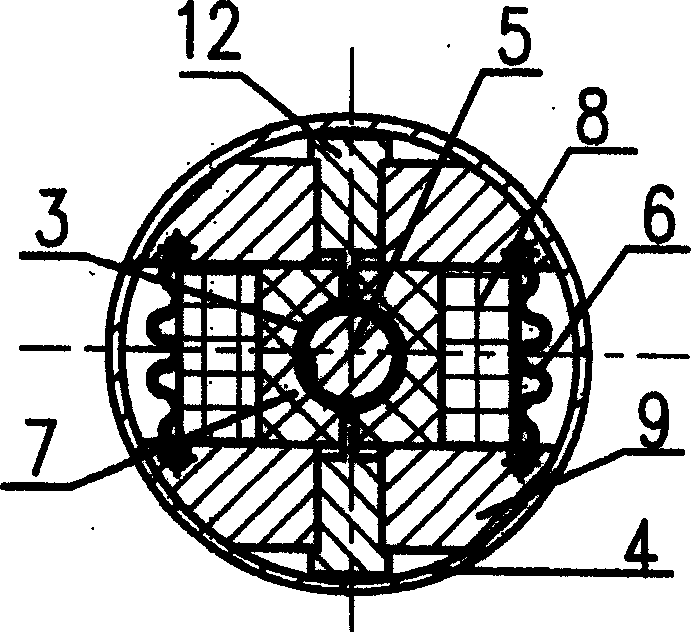

Pressure sensor of magnetic excitation vibrating cylinder

A pressure sensor and vibrating cylinder technology, applied in the direction of measuring fluid pressure, measuring fluid pressure, instruments, etc. through electromagnetic components, can solve the problems of high energy consumption, difficult mass production, and difficulty in closed-loop debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

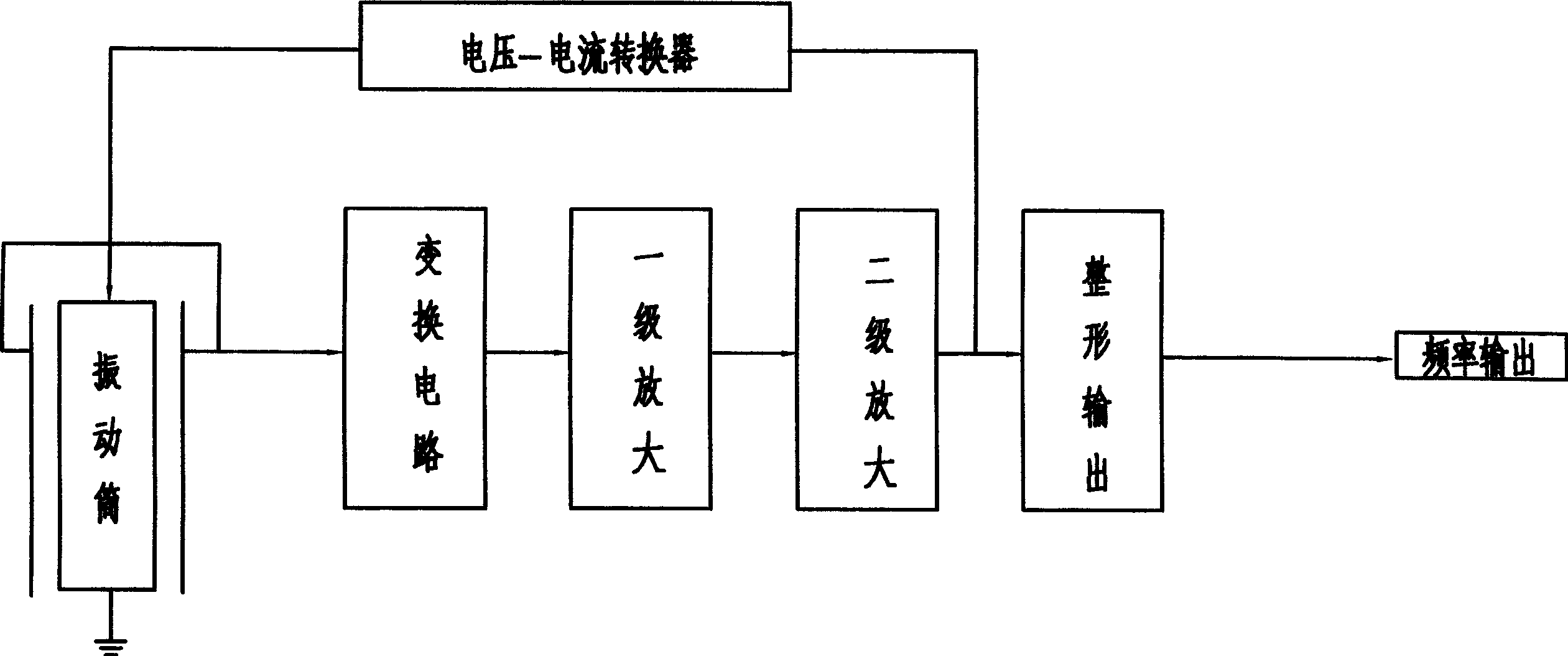

[0013] The excitation circuit is the excitation source for the sensor. Transformation circuit, primary amplification, and secondary amplification all use high-impedance TL084 operational amplifiers, voltage-current converters use conversion transformers, and the shaping output is composed of micro-transistor BC187-16, MC78L05 three-terminal voltage regulator and voltage regulator ZMM4V7.

[0014] The conversion circuit converts the charge on the ceramic capacitor into a voltage, and amplifies the weak voltage through the primary and secondary amplification, and a part of the signal outputs a frequency signal after the shaping circuit. The frequency of this signal is the resonance frequency of the thin-walled cylinder. The other part is introduced into the excitation terminal through the voltage-current converter. When the frequency of the feedback signal is the same as the natural frequency of the thin-walled cylinder resonance, a closed-loop positive feedback is formed, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com