Anticorrosive wear-resistant spiral dog nail and its production process

A technology of spiral spikes and production process, which is applied to metal material coating process, roads, tracks, etc., can solve the problems of labor, high cost, time-consuming, etc., and achieve the effect of saving labor, good anti-corrosion performance and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

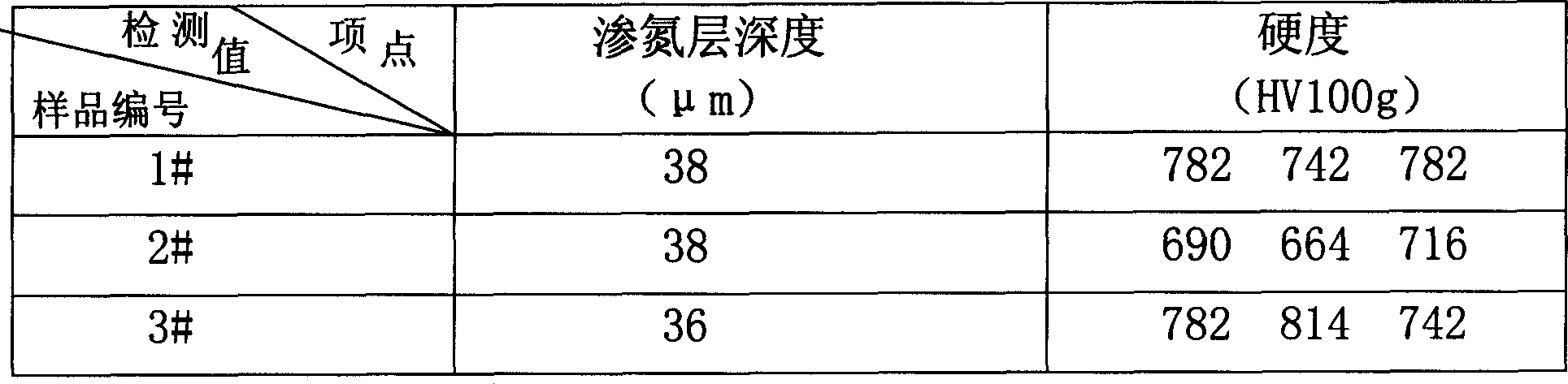

[0033] The heat treatment process of the anti-corrosion and wear-resistant spiral road stud of the present invention is as follows: spiral road stud blank-blank cleaning treatment-into the furnace-heat treatment-cooling out of the furnace-oiling:

[0034] Spiral spike blanks: several spiral spikes and matching nuts are made of Q235A carbon structural steel. High .25 special thread;

[0035] Blank cleaning treatment: clean up the oil and impurities on the surface of spiral spikes and nut blanks to avoid affecting the heat treatment layer;

[0036] Furnace entry: Hang clean spiral spikes and nuts in a closed heat treatment furnace. The gas composition and ratio in the heat treatment furnace are: ammonia: carbon dioxide: air = 100:5:15; the temperature is 590°C; the furnace pressure : 700Pa; then keep warm for heat treatment for 2.5 hours.

[0037] Cool down and take out of the furnace; when the power is turned off and the furnace temperature is lowered to 500°C, the ammonia ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com