Lithium secondary cell

A lithium secondary battery and non-aqueous electrolyte technology, which is applied in secondary batteries, primary batteries, lithium storage batteries, etc., can solve the problems of inability to obtain storage characteristics, and achieve the effect of improving storage characteristics and inhibiting reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

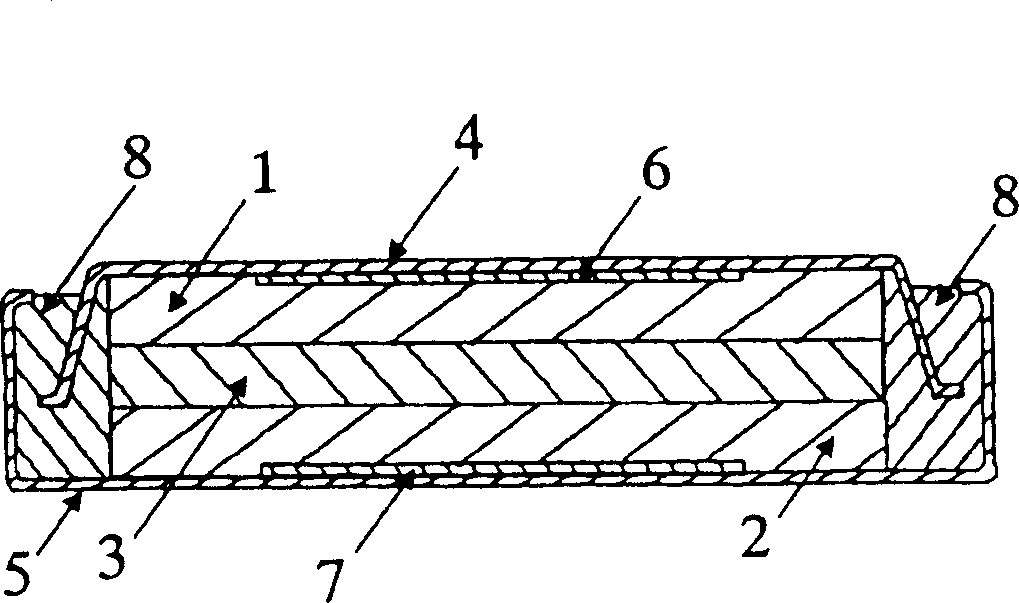

Image

Examples

Embodiment 1-1

[0024] [making of positive electrode]

[0025] The spinel-structured lithium manganese oxide (LiMn 2 o 4 ) (powder), carbon black (powder) as a conductive agent, and fluororesin (powder) as a binder were mixed at a weight ratio of 85:10:5 to prepare a positive electrode mixture. This positive electrode mixture was molded into a disc shape, and dried in vacuum at 250° C. for 2 hours to obtain a positive electrode.

[0026] [Production of Negative Electrode]

[0027] A lithium-aluminum-manganese (Li-Al-Mn) alloy was prepared by electrochemically intercalating lithium into an aluminum-manganese (Al-Mn) alloy having a manganese content of 1% by weight. Lithium was intercalated in an amount equivalent to 100 mAh / g. This alloy was punched out into a disc shape to obtain a negative electrode.

[0028] [Preparation of non-aqueous electrolyte solution]

[0029] In a separate solvent of diethylene glycol dimethyl ether (Di-DME), lithium bis(trifluoromethylsulfonyl)imide (LiN(CF 3...

Embodiment 1-2

[0035] Battery A2 of the present invention was assembled in the same manner as in Example 1-1 except that a nonwoven fabric made of quartz glass fiber was used as the separator.

Embodiment 1-3

[0037] Inventive battery A3 was assembled in the same manner as in Example 1-1, except that a nonwoven fabric made of sodium glass fiber was used as the separator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com