Container for storaging high purity liquid chemical

A chemical and high-purity technology, applied in the field of containers for storing liquid chemicals, can solve the problems of container 1 expansion, deformation, danger, dumping, etc., and achieve the effect of less bending area, maintaining stability of placement, and reducing dead angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

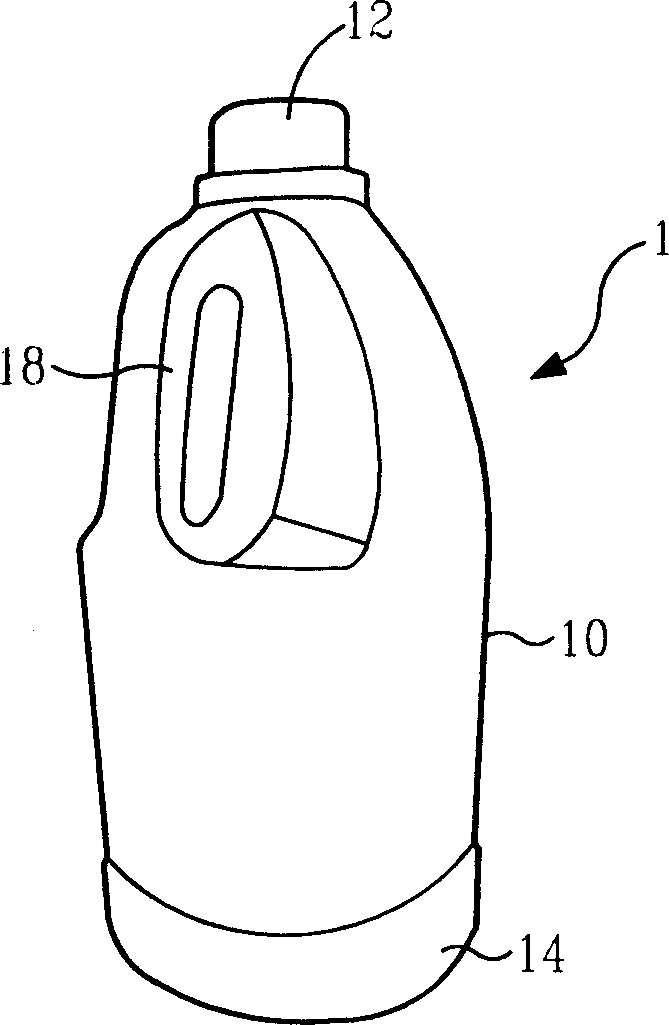

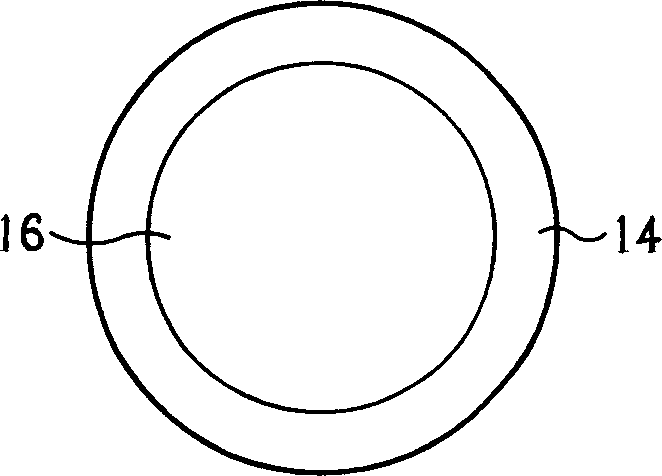

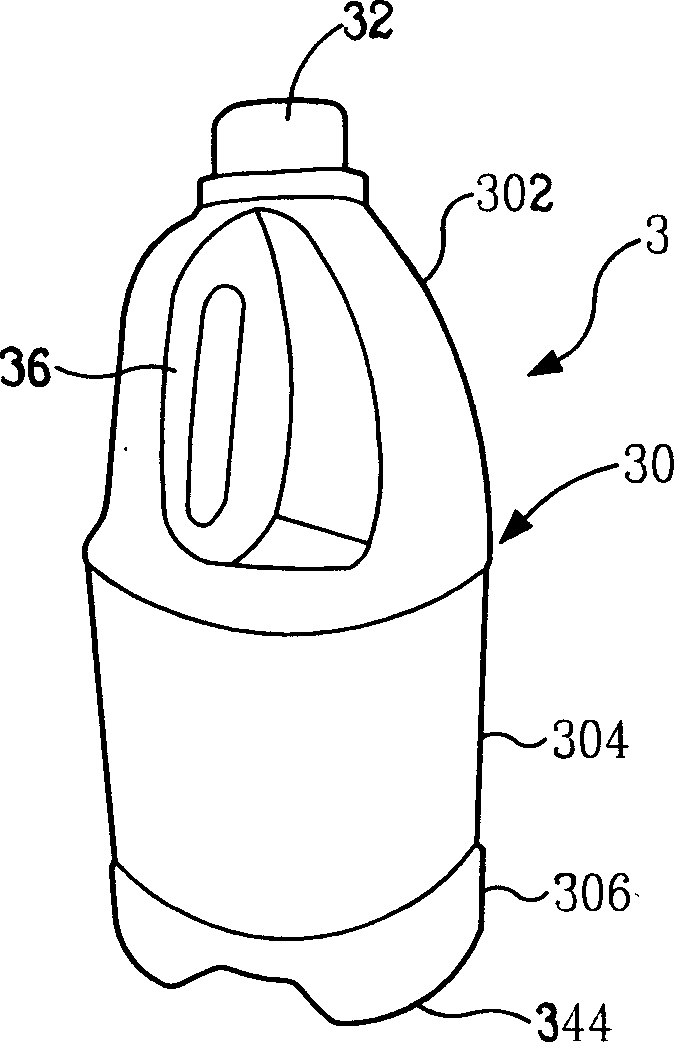

[0023] The container used for storing high-purity liquid chemicals in the present invention includes a hollow body and a sealing cover; the hollow body is used for holding high-purity liquid chemicals, such as strong acid, strong alkali and organic / inorganic solution, etc., and its top is placed There is an opening, the periphery of the bottom of which is provided with three protrusions arranged in a non-colinear arrangement and extending downwards respectively to support the hollow body, and the sealing cover is used to seal the opening at the top of the hollow body. The non-collinear arrangement of three convex columns at the bottom of the container used for storing high-purity liquid chemicals in the present invention constitutes a coplanar surface, providing a stable bottom support surface for the container. When the container of the present invention used for storing high-purity liquid chemicals increases the internal pressure of the container due to the increase of the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com