Extraction and separation of proto flower haematochrome and preparation method of its derivatives

A technology of pigment derivatives and bonuses, applied in the fields of food preparation, chemical instruments and methods, food science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

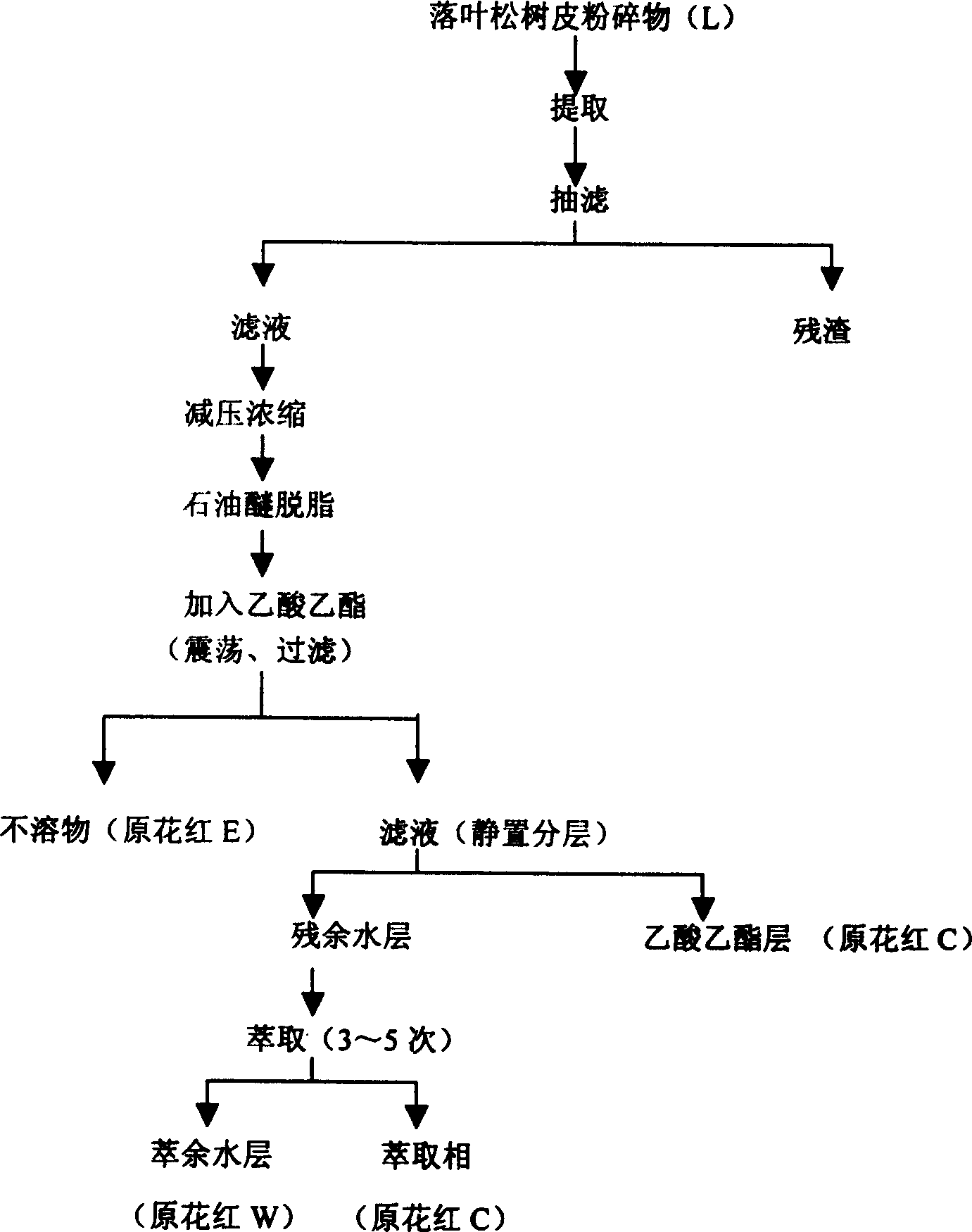

[0038] Step 1: Preparation of Crude Proanthocyanin

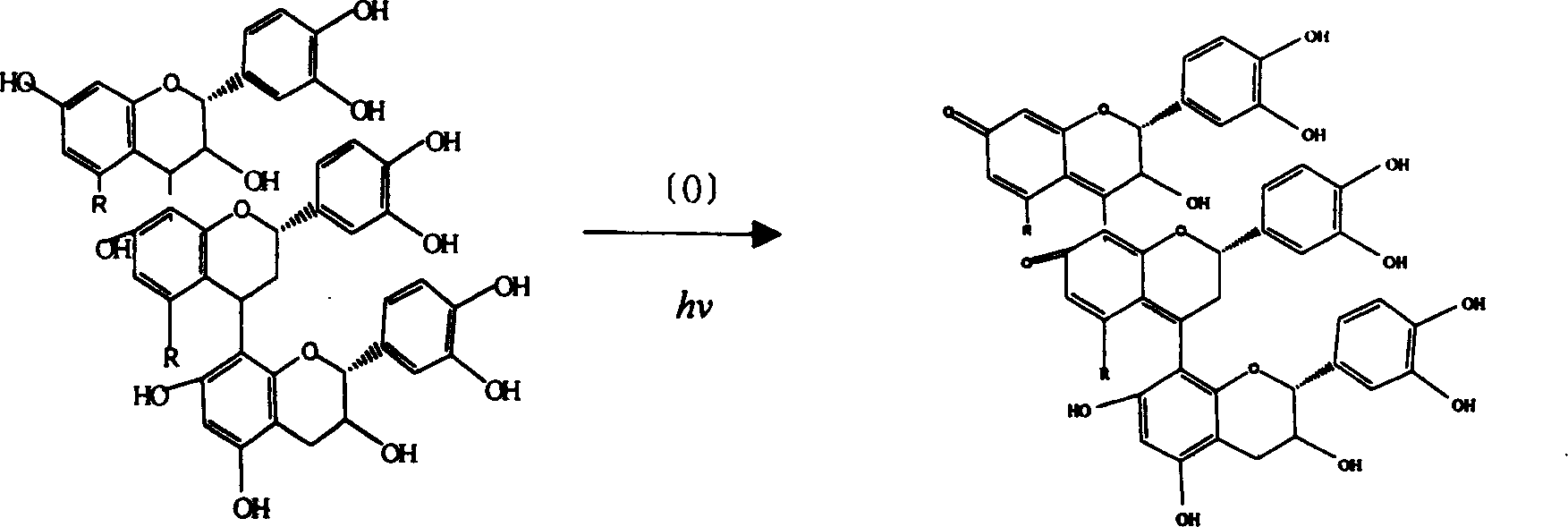

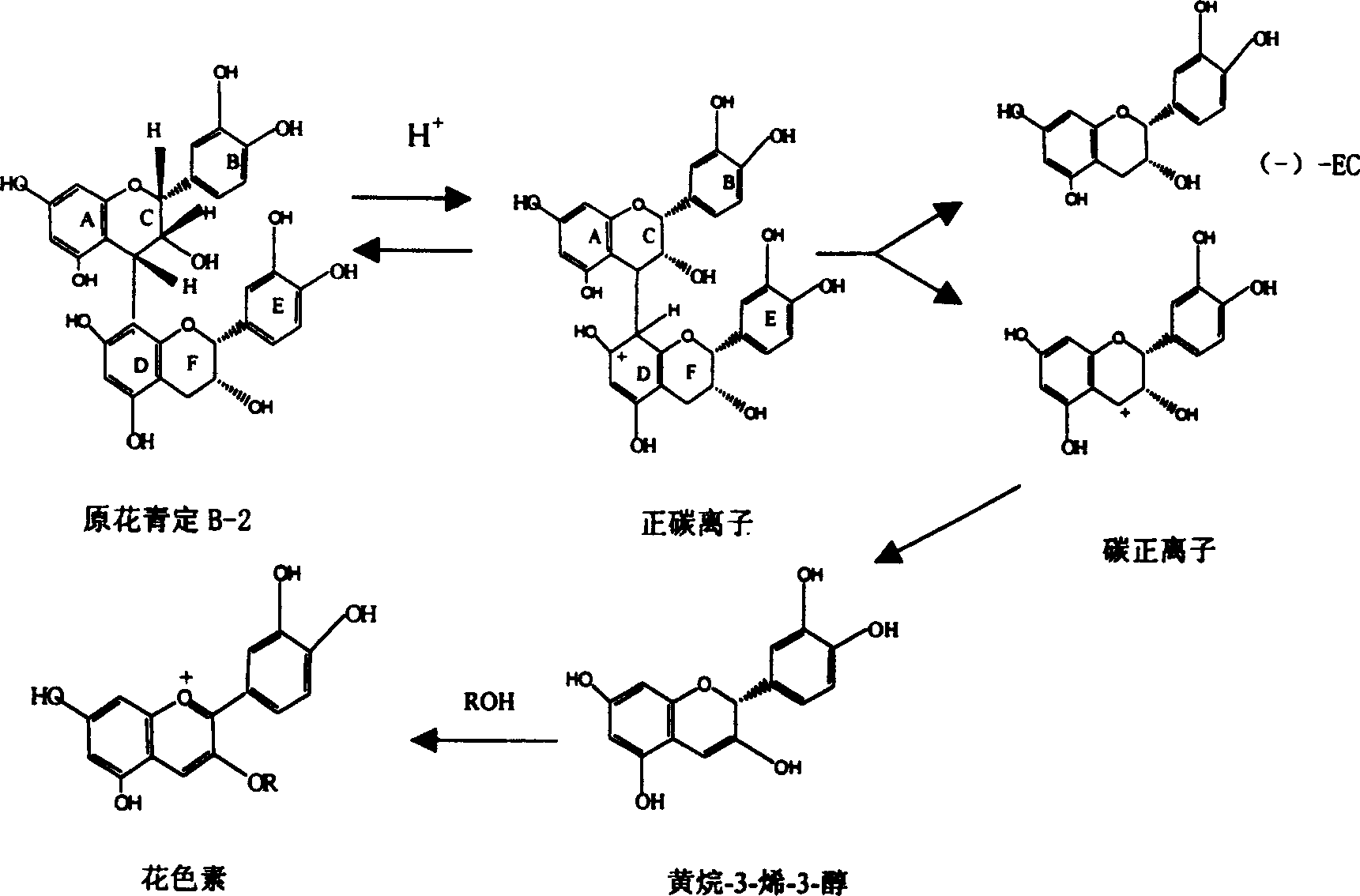

[0039] Naturally air-dried larch (Larix gmelini) bark is used as raw material, crushed into particles with a particle size of about 1-15 mm, and sieved to remove impurities. Weigh 10Kg of the above-mentioned raw materials, add 80L of 75% acetone aqueous solution, extract in a vacuum reflux tank at a temperature of 35±5°C, and reflux for 8 hours at normal pressure, and then discharge. Through coarse filtration, remove the residue and obtain the filtrate, pump the filtrate into a vacuum reflux tank, concentrate under reduced pressure to recover acetone, discharge the material, and put the material liquid into the extractor to cool to room temperature. Then add petroleum ether for extraction to remove resins and gums. Thus, the extract of proanthocyanidin was obtained, or 1.76Kg of crude pigment product (LPR) was obtained by spray drying, with a yield of about 18%. The molecular structure and coloration principle of the main ...

Embodiment 2

[0045] Step 1: Preparation of Crude Proanthocyanin

[0046] Naturally air-dried, uncrushed larch (Larix gmelini) bark blocks were used as raw materials, sieved to remove impurities, weighed 15Kg of the above raw materials, added 50L of 95% ethanol, soaked at room temperature for 8-12 hours, and then moved into Add 100L of the above-mentioned ethanol solution to the multi-functional stainless steel extraction tank, start the circulation pump at a temperature of 75±5°C, and force reflux to extract for 2 hours, then discharge the filtrate and collect it. Then add 100L of the above-mentioned ethanol solution to the extraction tank, extract for 1 hour according to the above-mentioned process, discharge and collect the filtrate. Then remove the slag in the tank, clean the extraction tank, then combine the filtrate obtained twice, pump into the multi-functional extraction tank, and recover the solvent under reduced pressure at a temperature of 35±5°C. The liquid was released, and af...

Embodiment 3

[0052] Step 1: Preparation of Crude Proanthocyanin

[0053] Naturally air-dried, uncrushed larch (Larix gmelini) bark blocks were used as raw materials, and impurities were removed by sieving, and four parts of the above raw materials were weighed, 10Kg each, and moved into No. 1, No. 2, No. 3 and No. 4 respectively In stainless steel extraction tanks, 80°C hot water is used as the extractant, and countercurrent extraction is used. The material in each tank is extracted 4 times. According to the calculation of a single tank, the amount of each addition is 200L, the total material: hot water=1:80, at a temperature of 80°C, start the stirring device, and extract for 1 hour each time, a total of 4 hours. Then discharge the feed liquid, concentrate under reduced pressure in a three-effect concentrator, and discharge the feed. After coarse filtration, put the feed liquid into the extractor to cool to room temperature, then add light oil to shake or stir, and wait for standing to se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com