Method for controlling molecular weight distribution of starch sugar

一种分子量分布、淀粉糖的技术,应用在糖的生产、食品制备、糖类生产等方向,能够解决影响功效和商业价值、生理功能干扰等问题,达到低代价、实现工业化生产、容易工业化生产的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

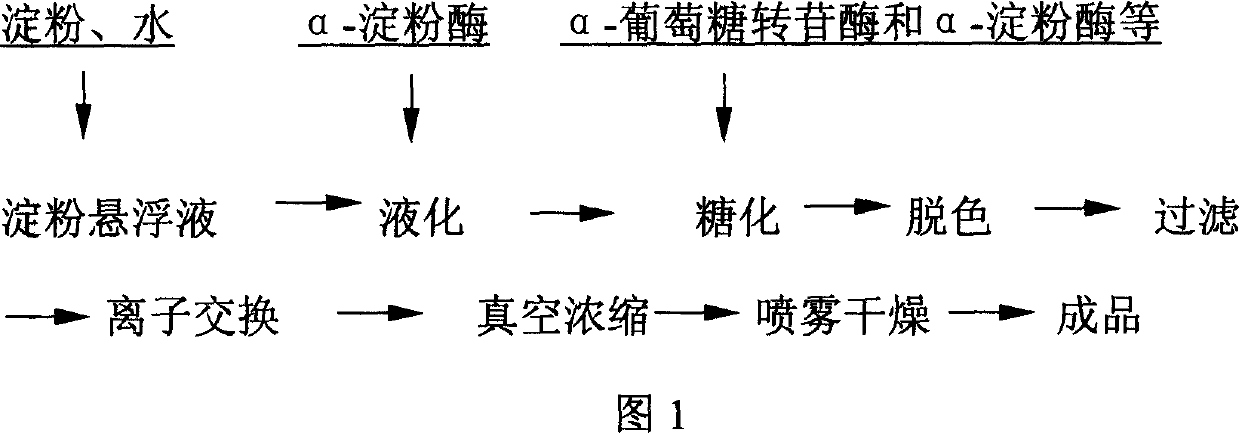

Image

Examples

Embodiment 1

[0019] Operation: Prepare starch slurry according to the ratio of 1 part of dry starch to 3 parts of water (W / W), and add CaCl with 0.012% (W / W) of dry starch 2 . use Na 2 CO 3 Adjust the pH to 5.5. Add high temperature resistant α-amylase with a dry starch content of 0.04 (W / W), and stir evenly. Keep the temperature at 100°C, liquefy with a jet liquefier, and control the DE value to 9. The liquefied liquid stays in the laminar flow tank for 30 minutes, and samples are taken for iodine color test. After the iodine color test is qualified, the liquefaction is terminated and the enzyme is inactivated. Saccharification, filtration, decolorization, desalination, concentration, etc. are carried out according to the general process, and finally the product is obtained. The content of glucose in the product is 11.9%, trisaccharide to pentasaccharide is 70.1%, maltose is 18.0%, isomaltose is 20.5%, maltotriose is 4.0%, panose is 25.2%, isomaltotriose is 9.2%, four Sugar and abo...

Embodiment 2

[0021] Operation: Prepare starch slurry according to the ratio of 1 part of dry starch to 2 parts of water (W / W), and add CaCl with 0.02% (W / W) of dry starch 2 . use Na 2 CO 3 Adjust to pH 6. Add high temperature-resistant α-amylase with a dry starch content of 0.05% (W / W), and stir evenly. Keep the temperature at 130°C, liquefy with a jet liquefier, and control the DE value to 10. The liquefied liquid stays in the laminar flow tank for 40 minutes, and samples are taken for iodine color test. After the iodine color test is qualified, the liquefaction is terminated and the enzyme is inactivated. Saccharification, filtration, decolorization, desalination, concentration, etc. are carried out according to the general process, and finally the product is obtained. The content of glucose in the product is 12.2%, trisaccharide to pentasaccharide is 70.9%, maltose is 16.9%, isomaltose is 20.8%, maltotriose is 3.8%, panose is 24.8%, isomaltotriose is 9.6%, four Sugar and above is...

Embodiment 3

[0023] Operation: Prepare starch slurry according to the ratio of 1 part of dry starch to 3 parts of water (W / W), and add CaCl with 0.015% (W / W) of dry starch 2 . use Na 2 CO 3 Adjust the pH to 6.5. Add high temperature resistant α-amylase with a dry starch content of 0.07 (W / W), and stir evenly. Keep the temperature at about 130°C, liquefy with a jet liquefier, and control the DE value to 12. The liquefied liquid stays in the laminar flow tank for 60 minutes, and samples are taken for iodine color test. After the iodine color test is qualified, the liquefaction is terminated and the enzyme is inactivated. Saccharification, filtration, decolorization, desalination, concentration, etc. are carried out according to the general process, and finally the product is obtained. The content of glucose in the product is 11.4%, trisaccharide to pentasaccharide is 69.4%, maltose is 19.2%, isomaltose is 19.7%, maltotriose is 3.8%, panose is 24.8%, isomaltotriose is 9.6%, four Sugar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com