Combustion gas convolution type engine

A technology for engines and heat engines, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve problems such as poor fuel economy, high exhaust gas pollution, and easy wear of contact seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

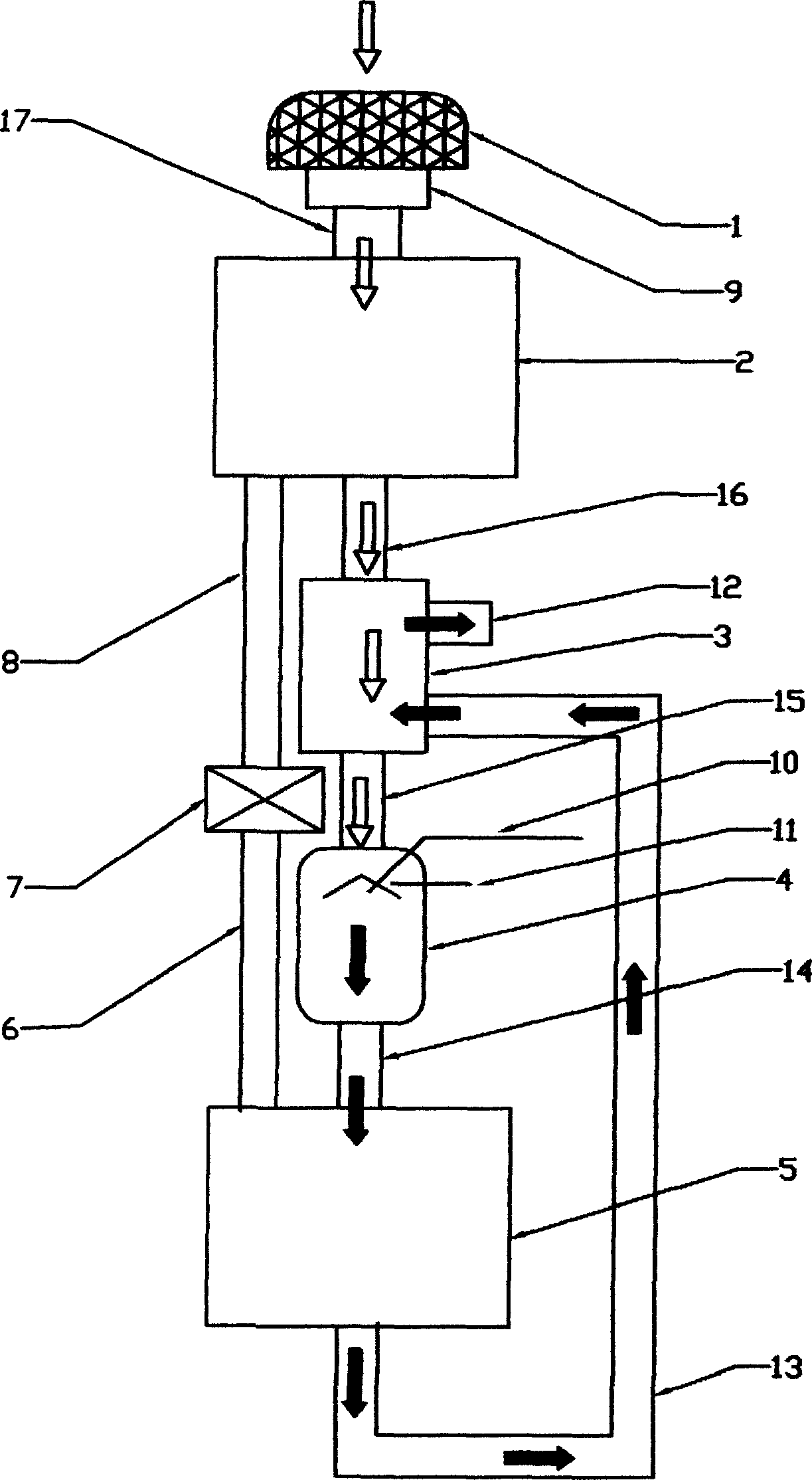

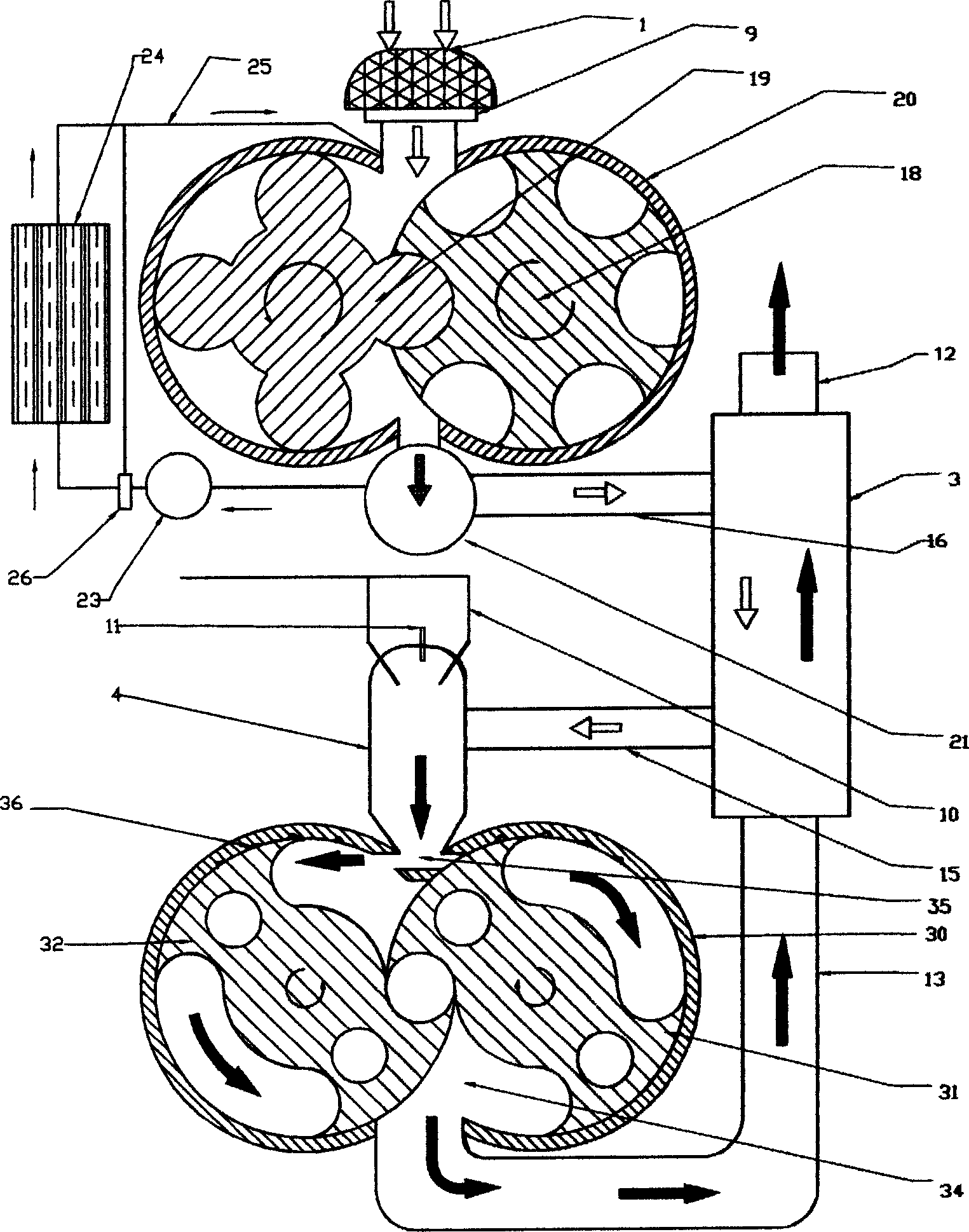

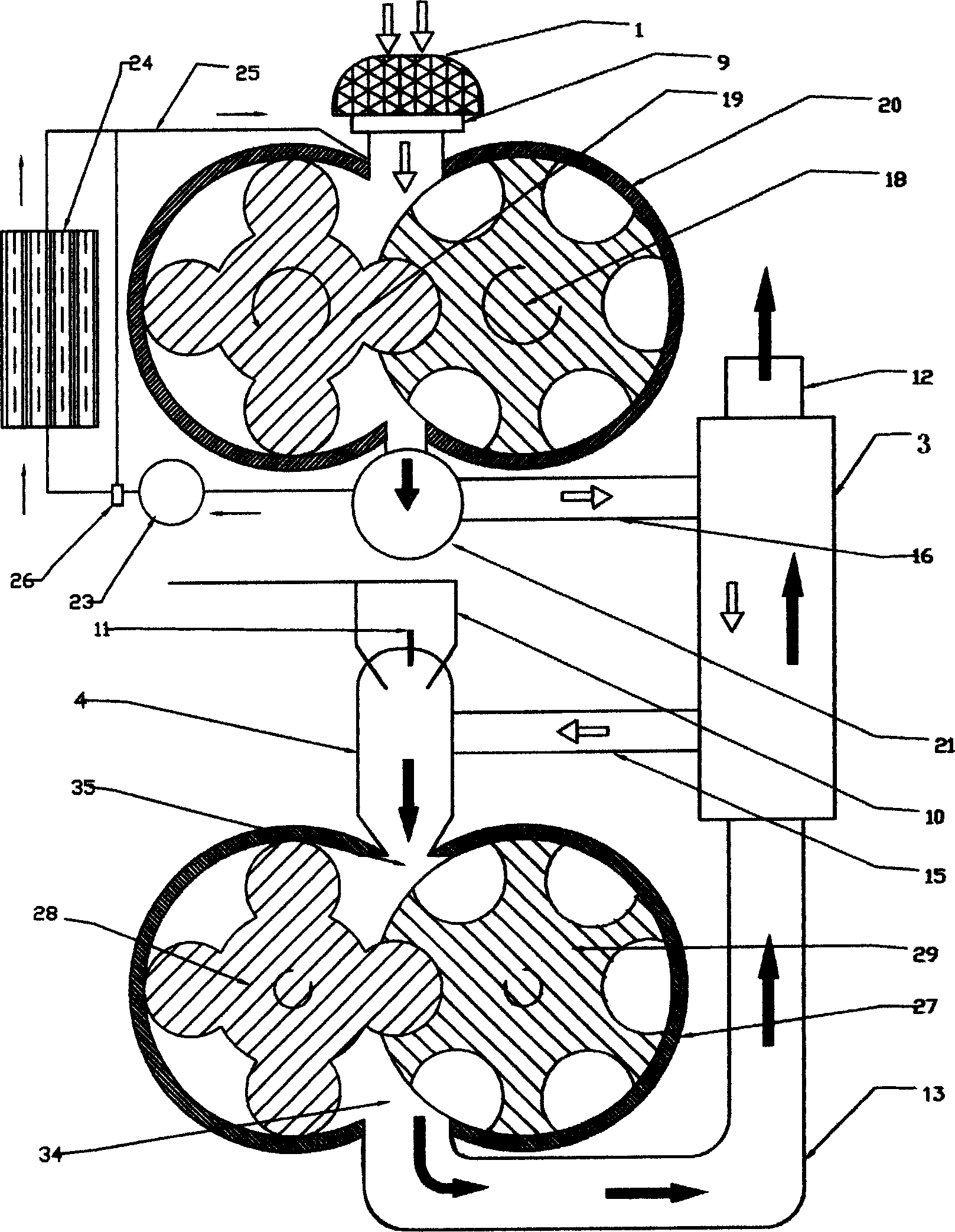

[0042] exist figure 1 In the process of the engine, the air enters the air filter (1) along the direction of the hollow arrow, enters the air intake pipe (17) of the screw compressor under the control of the air intake volume controller (9), and then enters the screw compressor (2), the air is compressed into high-pressure gas by the screw compressor (2), enters the regenerator (3) through the air exhaust pipe (16) of the screw compressor, and after absorbing the heat of the discharged gas, the temperature of the compressed air rises, And enter the combustion chamber (4) through the air exhaust pipe (15) of the regenerator, the fuel pipe and the fuel injector (10) spray fuel and mix with air and burn to generate high-temperature and high-pressure gas, and the high-temperature and high-pressure gas is exhausted through the combustion chamber The trachea (14) enters the volume work device (5), expands and does work in the volume work device (5), pushes the volume work device (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com