Preparation process of microball porous asphaltum group charring microball

A technology based on pitch and carbon microspheres, which is applied in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of no practical value and concentration less than 1.0wt%, and achieve good sphericity, controllable ball diameter, and high yield. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

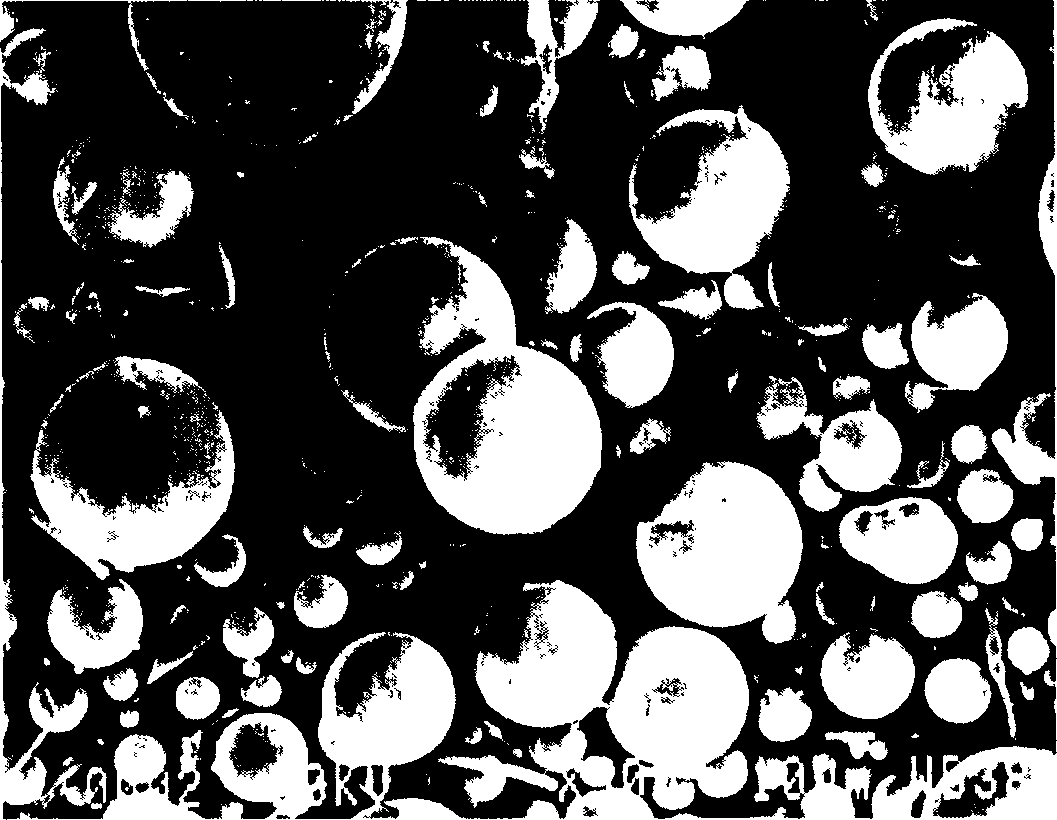

[0016] Add 300ml of asphalt tetrahydrofuran solution with a concentration of 0.33g / ml to 2000ml of PVA glycerol solution with a concentration of 5g / L, heat it to 150°C at a rate of 2.0°C / min in a stirred tank at normal pressure, and keep the temperature until all THF is evaporated Take out, filter after cooling. The filter cake was dried at 110°C, heated in air at 5°C / min to 240°C, oxidized for 5 hours and then heated to 1000°C at 10°C / min under nitrogen protection, and carbonized for 15 minutes to obtain pitch-based carbon microspheres. The average spherical diameter is 32.0um, and the specific surface area is 403m 2 / g. Electron microscope photos such as figure 1 .

Embodiment 2

[0018] Add 300ml of asphalt tetrahydrofuran solution with a concentration of 0.33g / ml to 2000ml of PVA glycerol solution with a concentration of 10g / L, heat it to 150°C at a rate of 2.0°C / min in a stirred tank at normal pressure, and keep the temperature constant until all THF is evaporated Take out, filter after cooling. The filter cake was dried at 110°C, heated in air at 5°C / min to 240°C, oxidized for 5 hours and then heated to 1000°C at 10°C / min under nitrogen protection, and carbonized for 15 minutes to obtain pitch-based carbon microspheres. The average spherical diameter is 19.0um, and the specific surface area is 435m 2 / g.

Embodiment 3

[0020] Add 300ml of asphalt tetrahydrofuran solution with a concentration of 0.33g / ml to 2000ml of PVA glycerin solution with a concentration of 20g / L, heat it to 150°C at a rate of 2.0°C / min in a stirred tank at normal pressure, and keep the temperature constant until all THF is evaporated Take out, filter after cooling. The filter cake was dried at 110°C, heated in air at 5°C / min to 240°C, oxidized for 5 hours and then heated to 1000°C at 10°C / min under nitrogen protection, and carbonized for 15 minutes to obtain pitch-based carbon microspheres. The average spherical diameter is 16.0um, and the specific surface area is 485m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com