Pull wheel type engine with multi-grade rocking rod

A power machine and wheel-type technology, applied in the direction of mechanical power generating mechanism, machine/engine, mechanical equipment, etc., can solve the problems of polluting the environment, large volume, low conversion efficiency, etc., and achieve energy saving, no pollution of the environment, and power output high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

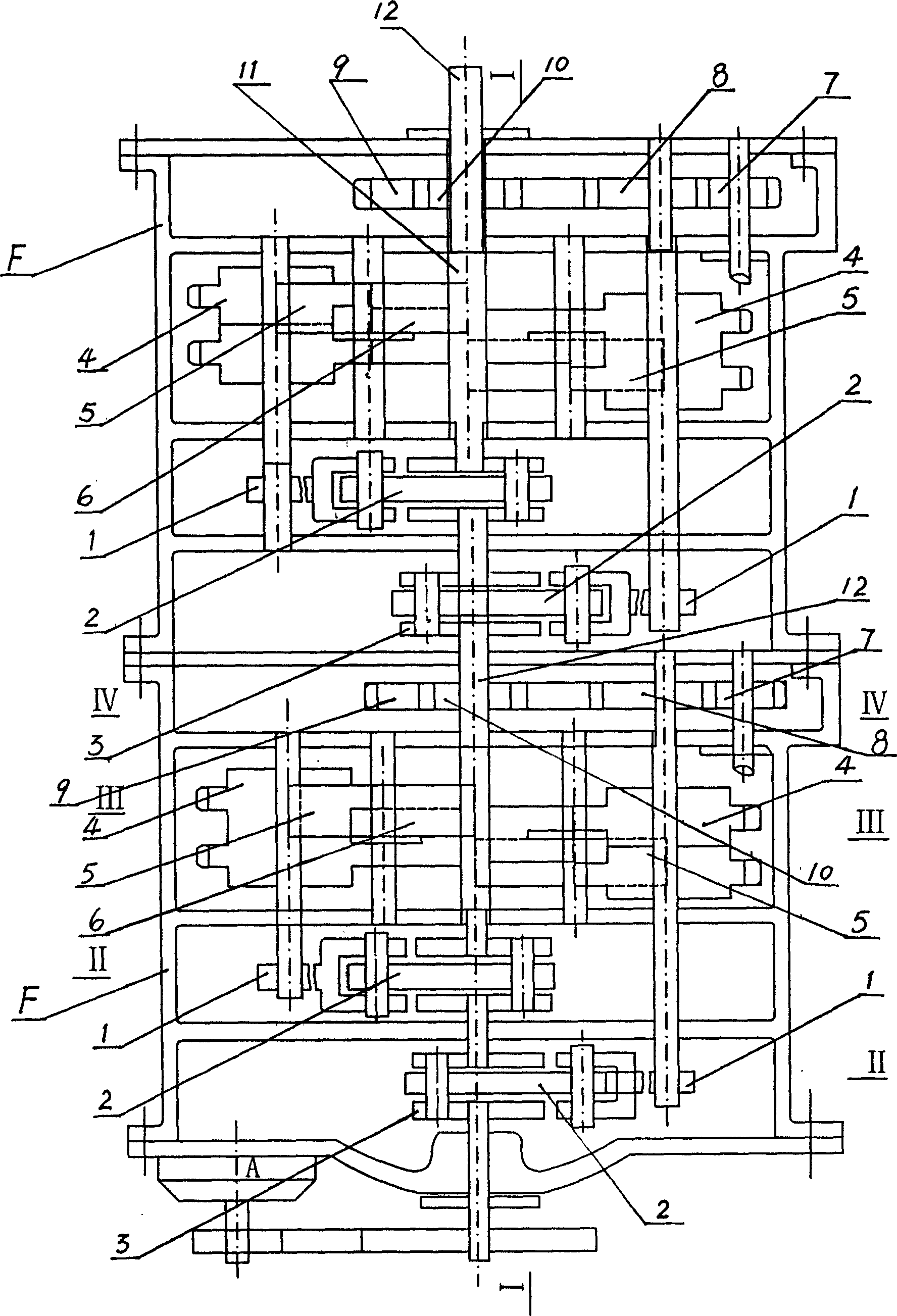

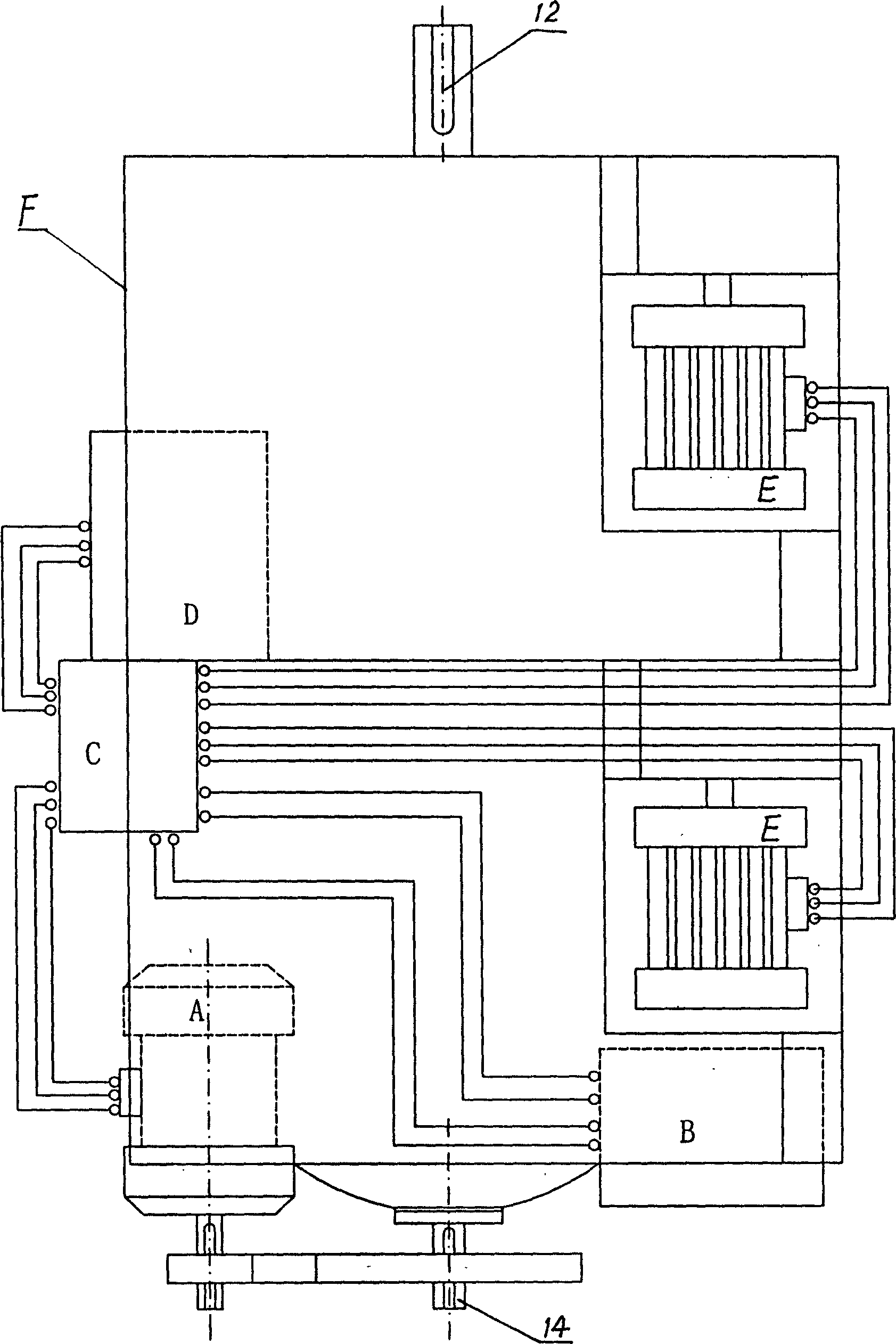

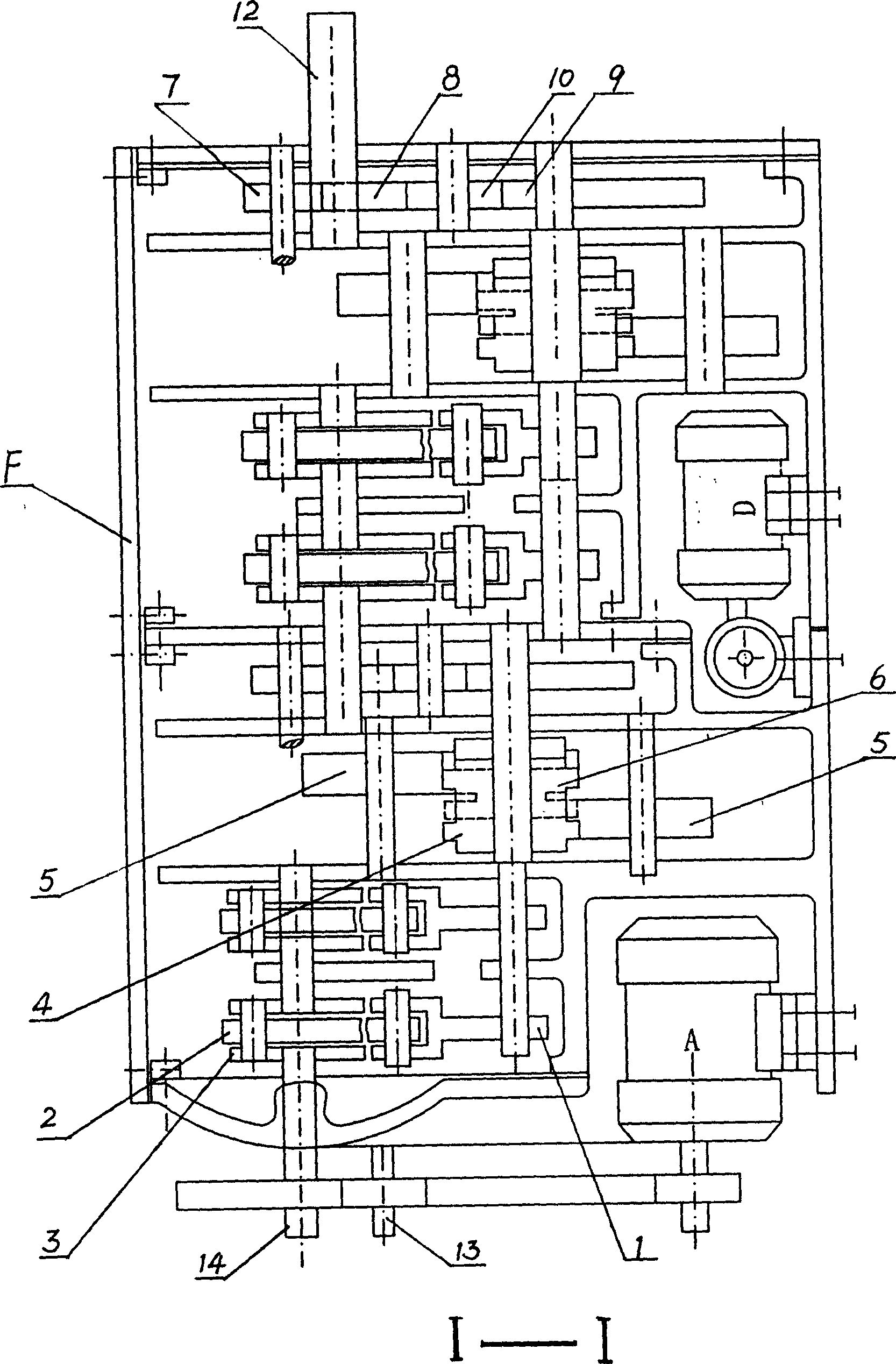

[0025] Multi-stage rocker detent power machine, such as figure 1 , figure 2 , image 3 As shown, it is composed of a box or a combination of boxes. The box (F) is equipped with a motor (A), a generator (E), a battery (B), and an oil pump (D). It includes three Most of them: transfer booster mechanism device, electric cycle centralized control device and oil pump spray lubrication device;

[0026] The generator (E) is power-connected with the output shaft of the power booster transmission device, the motor (A) is power-connected with the output shaft of the power booster transmission device, and the generator (E) is connected with the electric cycle centralized controller (C) in the electric cycle centralized control device. ) connection, the battery (B) is connected with the electric cycle centralized controller (C) double-circuit line; the electric cycle centralized controller (C) is connected with the oil pump (D) line.

[0027] In this embodiment, the two-stage rocker p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com