Ultrathin core assembly for synthetising catalyst coated membrane fuel cell by direct method

A proton exchange membrane and core component technology, which is applied in the field of preparing ultra-thin core components by direct method, can solve the problems of poor continuity and uniformity, low fuel cell electrical output, etc., and achieves low production cost and high battery output performance. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

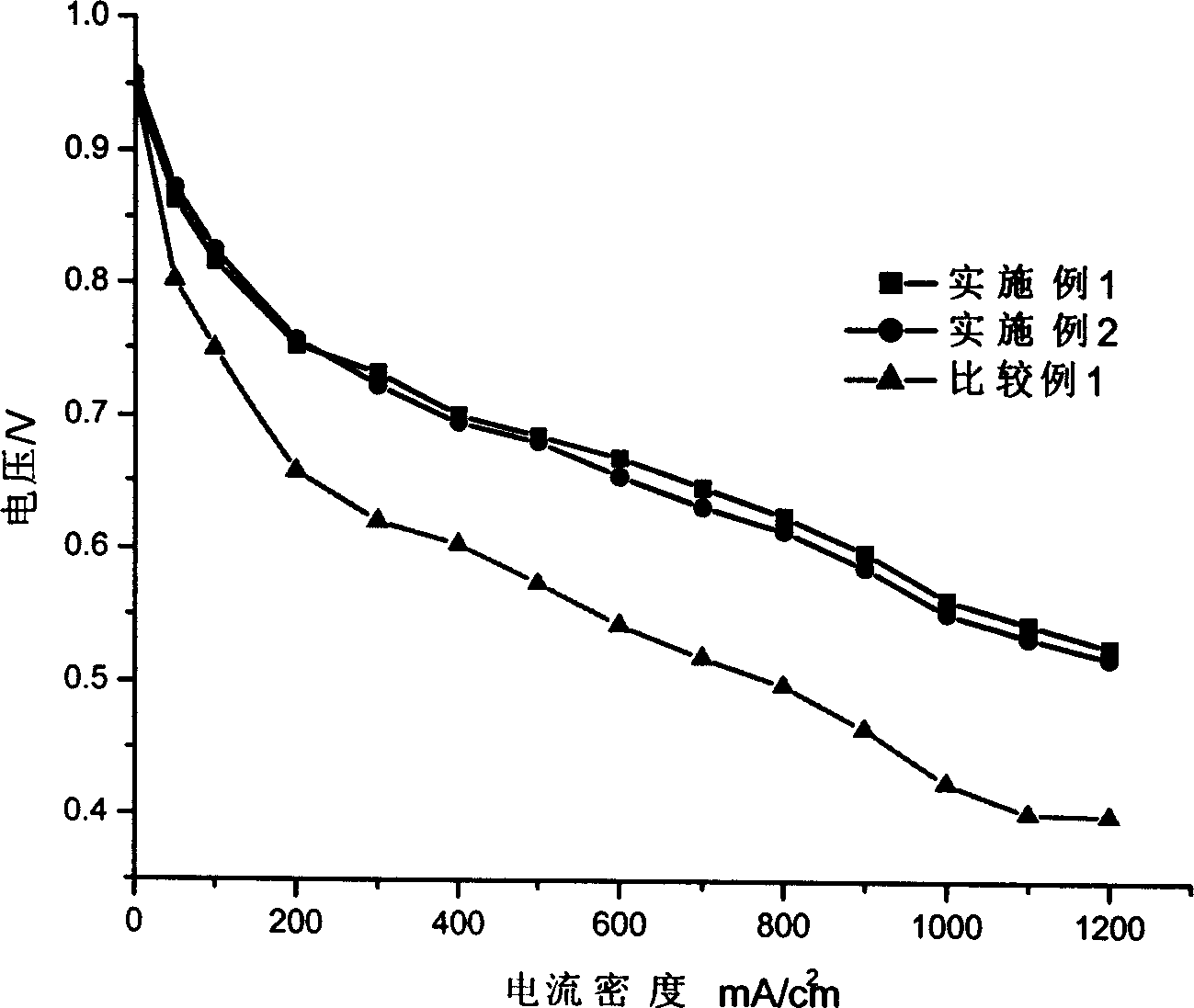

Embodiment 1

[0025]Ultrathin CCMs for proton exchange membrane fuel cells were prepared by laser printing technology. The slurry and powder with catalytic activity are prepared according to the ratio of electrocatalyst / proton exchange resin / hydrophobic agent / solvent / surfactant of 3:1:1:300:0.3. Take 6g of Pt / C electrocatalyst (produced by Johnson Matthey Company, the average particle diameter of the catalytically active particle Pt is 3nm, and the Pt loading is 40wt%) 1g, wet evenly with 5ml of deionized water, add 560ml of deionized water and 0.6g Polyvinyl alcohol (PVA), ultrasonically stirred for 20min. Then add 40g 5wt% Nafion® solution (produced by duPont company, 5wt% is Nafion® resin, about 95wt% is water, ethanol, isopropanol and other low-boiling alcohol components) and electric stirring for 10h, rotating speed 800r / h. Add 3.3g of 60wt% PTFE suspension, and ultrasonically stir for 30min to prepare a slurry. The slurry was filtered with suction and dried under vacuum at 80 °C for...

Embodiment 2

[0030] Ultrathin CCMs for proton exchange membrane fuel cells were prepared by electrostatic printing technology. The preparation of catalytically active slurry and powder, the pretreatment method of Nafion®111 membrane, and the single cell assembly and performance testing methods are the same as those in Example 1. The electrophotographic principle is used to transfer the powder with catalytic activity to the proton exchange membrane. Take a blank XEROX copier toner cartridge, put the powder into the toner cartridge and shake it evenly, and put it back into the copier. The copy density setting value is in the middle range. Make a piece of printing paper with a 5cm×5cm black pattern, and determine the position on the copy panel. A 6cm×6cm Nafion®111 film was adhered to the surface of a PTFE film (size 10cm×10cm, film thickness 100 μm, non-oriented film) and put into a paper box. The copying process is started and the powder is transferred to one side of the proton exchange m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com