Concrete modified by steel fiber enhanced polymer and preparation method

A technology of steel fiber and polymer, which is applied in the field of steel fiber reinforced polymer modified concrete and its preparation for the rigid pavement of concrete bridge deck, which can solve the problems of poor performance and impact resistance, etc., and achieve high bonding Effects of performance, high ductility, and low permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

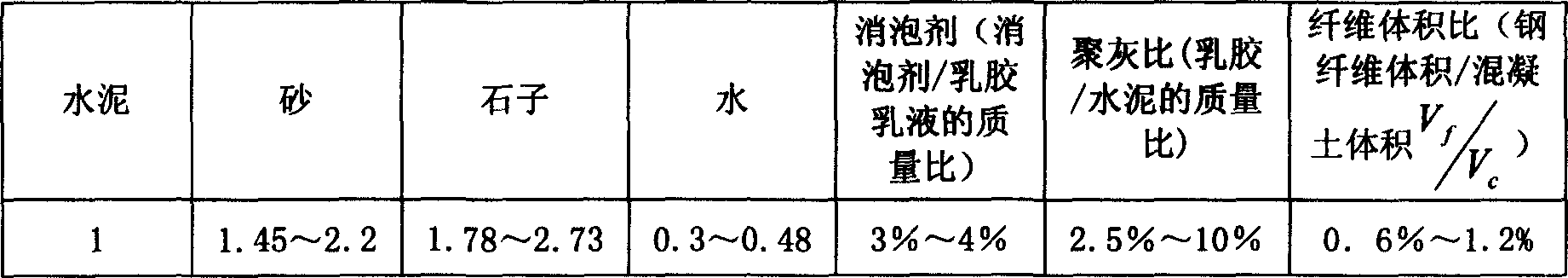

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of steel fiber reinforced polymer modified concrete is as follows:

[0031] (1) Clean the medium sand and stones and keep them in a dry state;

[0032] (2) After the steel fiber is poured out from the bag, check and remove the steel fiber with rust and agglomeration;

[0033] (3) The mixture of latex emulsion and defoamer is obtained after the defoamer and latex emulsion are prepared and stirred evenly in a mass ratio of 3.8%: 1;

[0034] (4) Prepare the batching bucket, add the mixture of water, latex emulsion and defoamer to the batching bucket successively according to the mass ratio of water and latex 0.45:7.5%, then stir evenly to obtain a uniform mixture;

[0035] (5) Put cement, medium sand, and stones into the mixing equipment according to the mass ratio of 1:2:2.3, and then put into the steel fibers according to the volume ratio of steel fibers and concrete of 1.2%:1, and mix evenly;

[0036] (6) Put the prepared latex emulsion, defoame...

Embodiment 2

[0039] The preparation method of steel fiber reinforced polymer modified concrete is as follows:

[0040] (1) Clean the medium sand and stones and keep them in a dry state;

[0041] (2) After the steel fiber is poured out from the bag, check it, remove the steel fiber with rust and agglomeration, and wait for use;

[0042] (3) mix defoamer and latex emulsion by mass ratio 3%: 1 and stir well to obtain the mixture of latex emulsion and defoamer;

[0043] (4) Prepare the batching bucket, add the mixture of water, latex emulsion and defoamer to the batching bucket successively according to the mass ratio of water and latex 0.35:5%, then stir evenly to obtain a uniform mixture;

[0044] (5) Put cement, medium sand, and stones into the mixing equipment according to the mass ratio of 1:1.5:1.8, and then put into the steel fibers according to the volume ratio of steel fibers and concrete of 1%:1, and mix evenly;

[0045] (6) Put the prepared latex emulsion, defoamer and water into ...

Embodiment 3

[0048] The preparation method of steel fiber reinforced polymer modified concrete is as follows:

[0049] (1) Clean the medium sand and stones and keep them in a dry state;

[0050] (2) After the steel fiber is poured out from the bag, check and remove the steel fiber with rust and agglomeration;

[0051](3) mix defoamer and latex emulsion by mass ratio 3.5%: 1 and stir well to obtain the mixture of latex emulsion and defoamer;

[0052] (4) Prepare the batching bucket, add the mixture of water, latex emulsion and defoamer to the batching bucket successively according to the mass ratio of water and latex of 0.3:10%, then stir evenly to obtain a uniform mixture;

[0053] (5) Put cement, medium sand, and stones into the mixing equipment according to the mass ratio of 1:1.45:1.78, and then put into the steel fibers according to the volume ratio of steel fibers and concrete of 1.2%:1, and mix evenly;

[0054] (6) Put the prepared latex emulsion, defoamer and water into the mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com