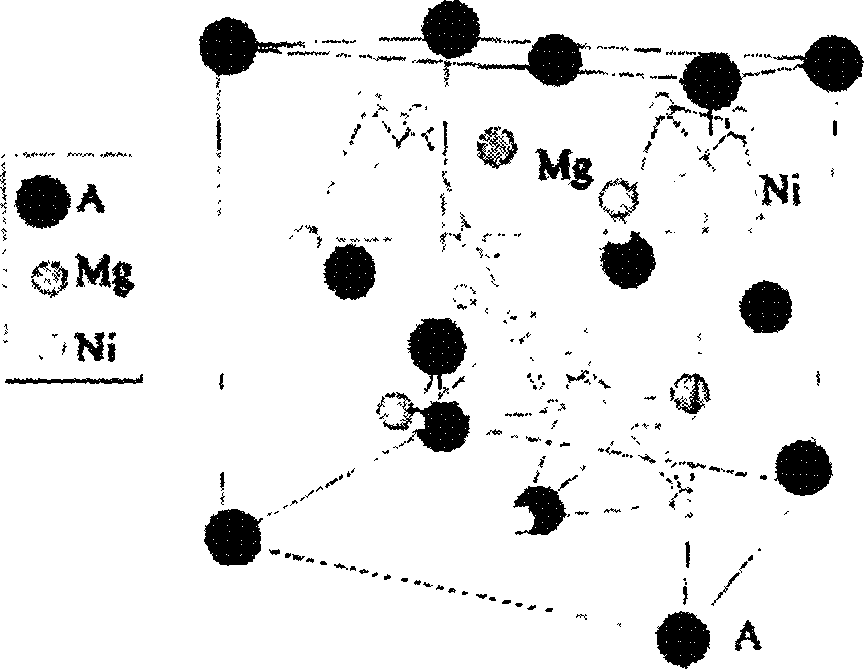

rEXmGYnI4-zAz alloy of storing hydrogen and uncrystallized preparation method

A technology for alloys and amorphous alloys, which is applied in the field of preparing hydrogen storage alloys and their amorphous materials, and can solve the problems of low hydrogen release, high H overpotential, electrochemical capacity, and low cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] According to the molecular formula LaMgNi 4 The atomic ratio of rare earth La, magnesium powder, nickel powder. A total of 10g of mixed powder is put into a stainless steel ball mill tank, the ball-to-material ratio is 10:1, the large, medium and small balls are reasonably matched, the total balls are 100g, the speed of the ball mill is 200r / min, and the ball milling process is protected by argon. Carry out down, reverse positive and negative every 30 minutes, take out after 6 hours of ball milling and press into a block sample, the size of the block sample is: 28×6×6mm, and the pressure is 57 kN. The bulk sample is packaged in a quartz tube under the protection of argon, and the argon pressure in the tube is 0.04-0.05Mpa. The quartz tube that encapsulates the sample is put into a resistance furnace for sintering treatment. The sintering process is: 673K, 2h→873K, 2h→973K, 2h. Raise from low temperature to high temperature, keep the temperature at each temperature for...

Embodiment 2

[0045] The master alloy NdNi (atomic ratio is Nd:Ni=1:1) is broken, according to the molecular formula NdMgNi 3.5 Ti 0.05 The atomic weight ratio, the crushed powder (particle size about 3mm) and the calculated amount of magnesium powder, nickel powder, titanium powder are mixed, a total of 10g, put into a stainless steel ball mill tank, the ball-to-material ratio is 10:1, large, medium and small Reasonably match the grinding balls, the total weight of the grinding balls is 100g, the speed of the ball mill is 150r / min, the ball milling process is carried out under the protection of argon, and the positive and negative are reversed every 30 minutes. After 10 hours of ball milling, take out and press into a block sample. : 28×6×6mm, the pressure is 60 kN. The bulk sample is packaged in a quartz tube under the protection of argon, and the argon pressure in the tube is 0.04-0.05Mpa. The quartz tube encapsulating the sample is put into a resistance furnace for sintering treatment...

Embodiment 3

[0047] The master alloy PrNi (atomic ratio is Pr:Ni=1:1) is broken, according to the molecular formula Pr 0.05 MgNi 3 For the atomic ratio of V, mix the crushed powder (with a particle size of about 2mm) and the calculated amount of magnesium powder, nickel powder, and vanadium powder, totaling 10g, and put it into a stainless steel ball mill tank. The ball-to-material ratio is 10:1, large and medium Reasonable matching of small grinding balls, the total amount of grinding balls is 100g, the speed of the ball mill is 180r / min, the ball milling process is carried out under the protection of argon, and the positive and negative rotations are reversed every 30 minutes. After 9 hours of ball milling, take out and press into a block sample. The specifications are: 28×6×6mm, and the pressure is 55 kN. The bulk sample is packaged in a quartz tube under the protection of argon, and the argon pressure in the tube is 0.04-0.05Mpa. The quartz tube encapsulating the sample was put into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com