Simple production process of feed additive calcium soap

A feed additive and fatty acid calcium technology, which is applied in the production process of fatty acid derivatives, can solve the problems of long construction period, complex equipment, and high infrastructure investment, and achieve the effects of simple operation, reduced material transfer, and reduced investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

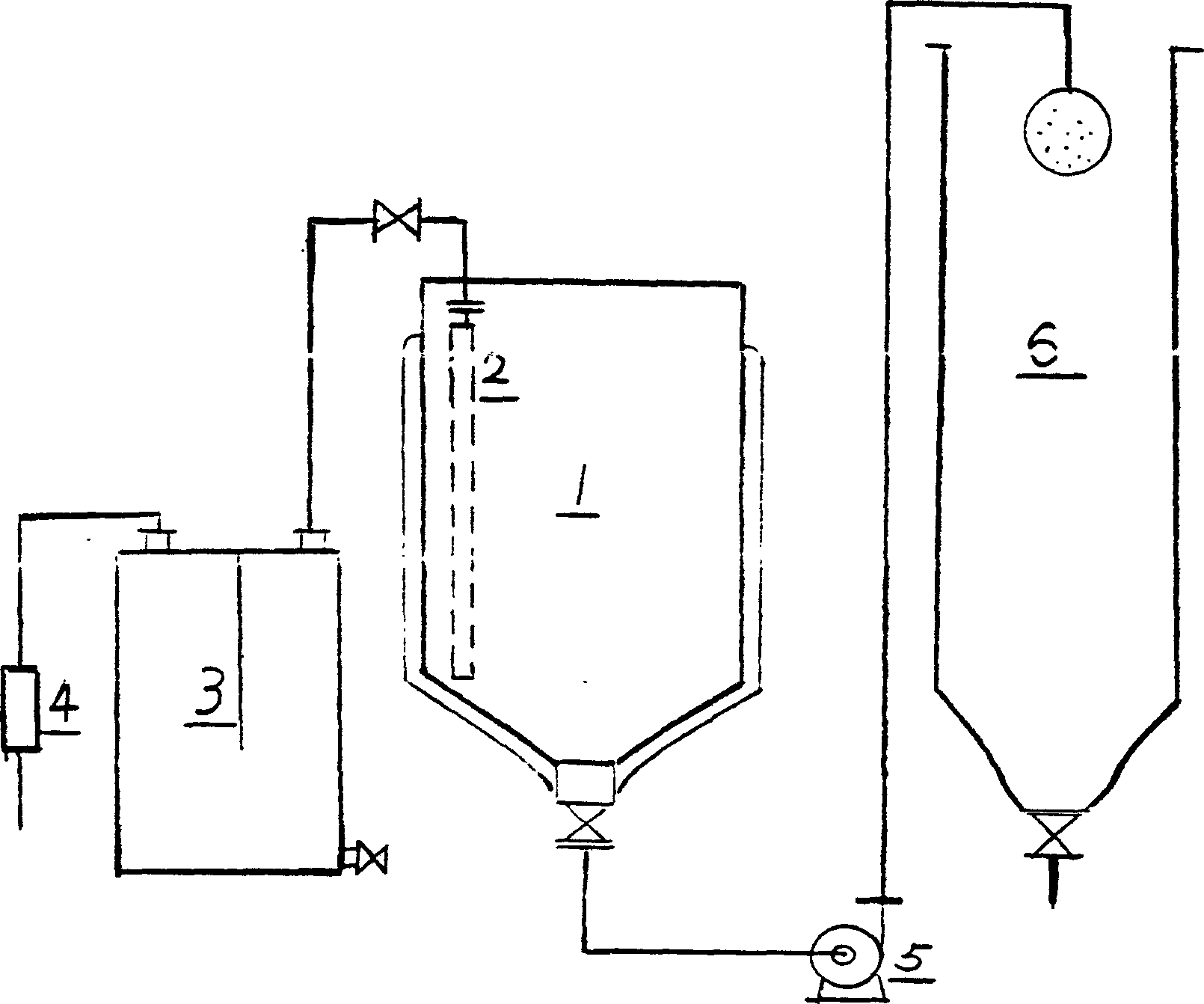

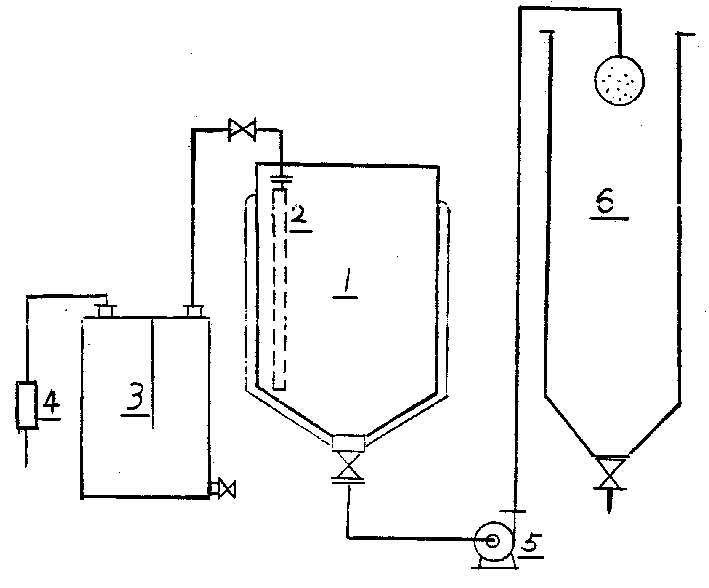

Image

Examples

Embodiment 1

[0010] Add 100 kilograms of fatty acids with 16 carbons to 20 carbons in the reactor 1, 600 kilograms of water to start the stirrer, maintain the temperature in the kettle to be 60 ℃ to 80 ℃, add 27 kilograms of sodium hydroxide solution with a concentration of 30%, and solid chlorination After stirring 21 kilograms of calcium for 6 to 10 minutes, slowly add 13 kilograms of sodium hydroxide solution with a concentration of 30%, and then stir for 30 minutes to stop stirring after the reaction is complete, insert the suction filter 2, and suck out the medium water to the negative pressure tank 3, Take out the suction filter 2, add 200 kg of washing water to the reaction kettle and stir for 3 minutes, then insert the suction filter 2 to suck out the washing water, take out the suction filter 2, start stirring to raise the temperature in the reaction 1 to 130℃~150℃ to vaporize the water Reactor mouth escapes, stop stirring, turn on the thick slurry pump 5, spray the molten material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com