Device for making microencapsulation cell

A microencapsulation and cell technology, applied in the field of biomedical engineering, can solve the problems of decreased microcapsule histocompatibility, uneven shape of microcapsules, uneven shape, etc., and achieve uniform shape, good permeability and biological phase. Capacitive, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

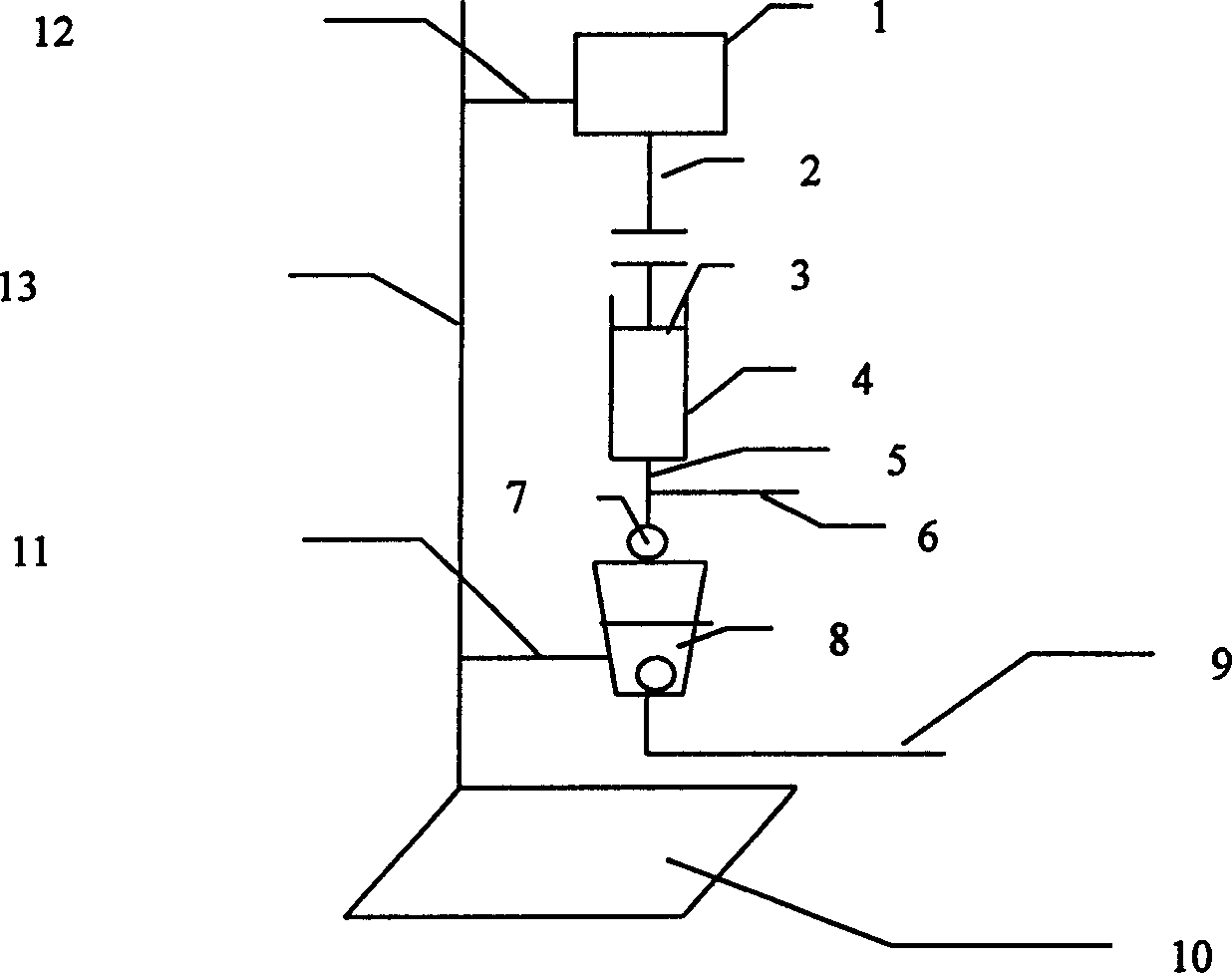

[0022] Embodiment 1 makes the glue bead of average diameter 400 μ m

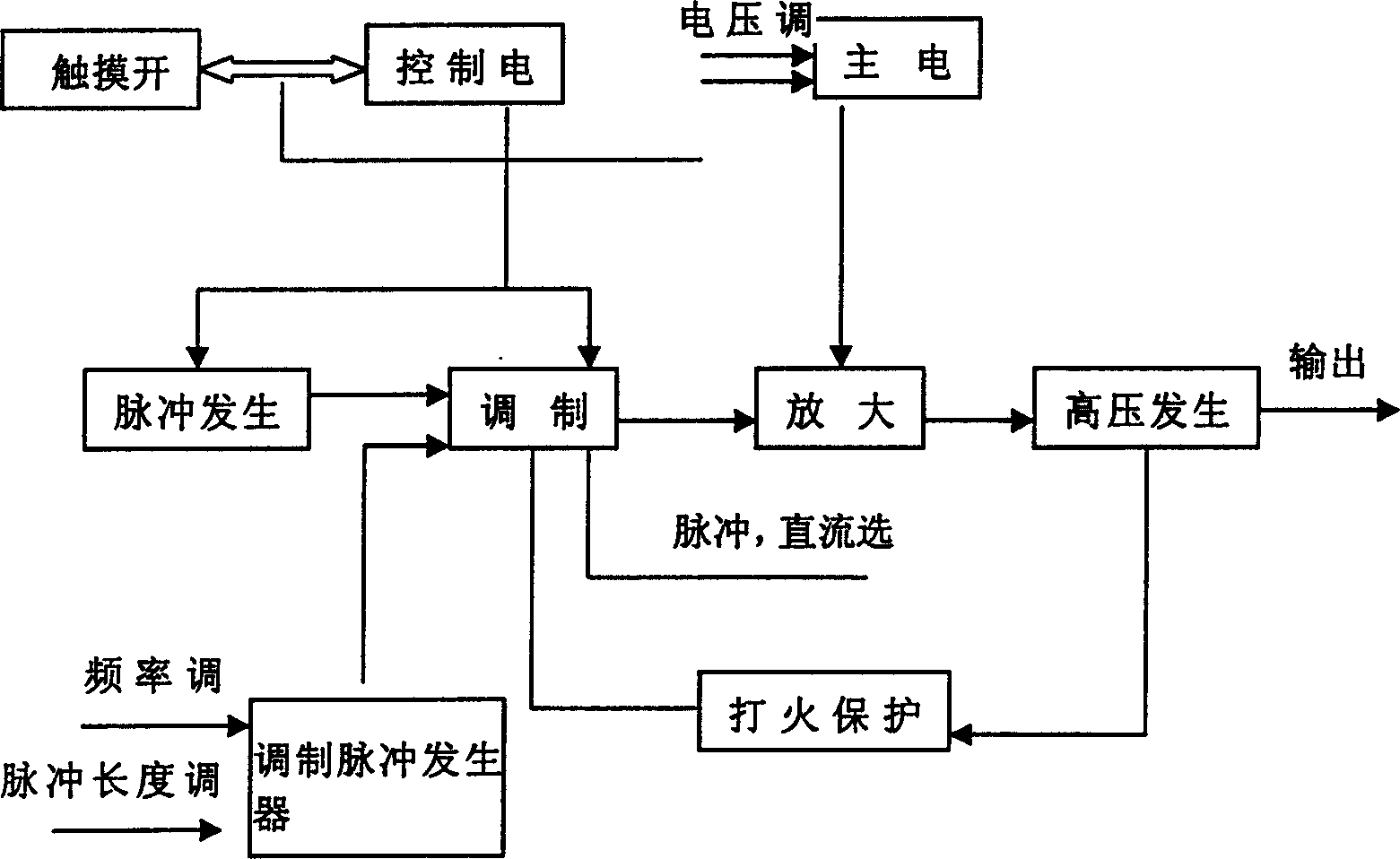

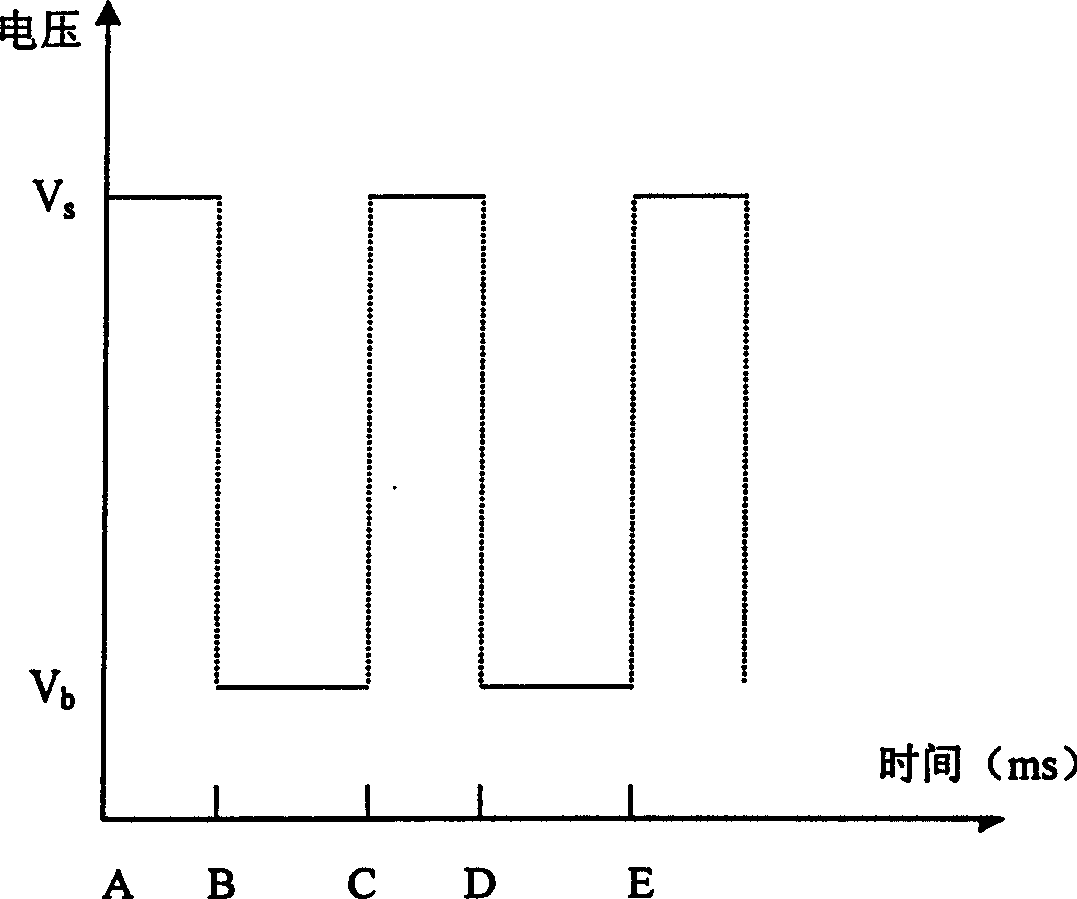

[0023] Put 2% sodium alginate solution (viscosity 250CPS) into a 20-100 ml syringe. Put the syringe into the syringe pump. The syringe is connected with a 22G needle with a diameter of 0.37 μm and a pillow slope of 17°. The positive pole of the high-voltage electrostatic generator is connected to the needle tip, and the negative pole is connected to the 2 solution to the bottom of the container. The distance between the liquid surface and the needle tip is 20mm, the voltage is 10KV, the frequency is 100Hz, the pulse length is 3ms, and the syringe pump speed is 2ml / s. Turn on the syringe pump and the high-voltage pulse electrostatic generator. A droplet is formed on the needle tip, and the CaCl 2 Glue beads formed in the solution. After 10 minutes the beads were collected and their diameters were observed under a microscope with a micrometer. The beads are complete and smooth.

Embodiment 2

[0024] Embodiment 2 makes the glue beads with an average diameter of 200 μm

[0025] The inner diameter of the needle is 0.24μm, the needle length is 100mm and the pillow slope is 0°. Other conditions are with embodiment 1. Glue beads with an average diameter of 212±14μm can be produced.

Embodiment 3

[0026] Example 3 Making Microcapsules Containing Pancreatic Islets

[0027] Will 4×10 3 An islet with a diameter of less than 300 μm was suspended in 4 ml of 2% sodium alginate solution with a viscosity of 250 CPS. Using the various parameters in Example 1, the droplets made were dropped into 2% CaCl 2 in solution. After 10 minutes the CaCl was aspirated off 2 solution. Wash the beads with PH 7.2 physiological saline, filter through a 60-mesh sieve, put them into 0.05% PLL with a molecular weight of 17KDa, incubate for at least 6 minutes, discard the PLL solution, wash with PH 7.0 physiological saline, discard the solution, and put Soak in 0.05% sodium alginate solution for 9 minutes, and then wash with PH 7.4 physiological saline. The microcapsules produced by this method are smooth and complete, with an average diameter of 400 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com