Electromagnetic speed-regulating electrical haulage coal cutter

A technology of electromagnetic speed regulation and coal shearer, which is applied in the direction of multiple motor speed regulation, motor speed or torque control, cutting machinery, etc., and can solve the problems of heavy maintenance workload, high cost, and easy wear of the commutator. Problems, to achieve the effect of low manufacturing and maintenance costs, simple control part, and low control power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

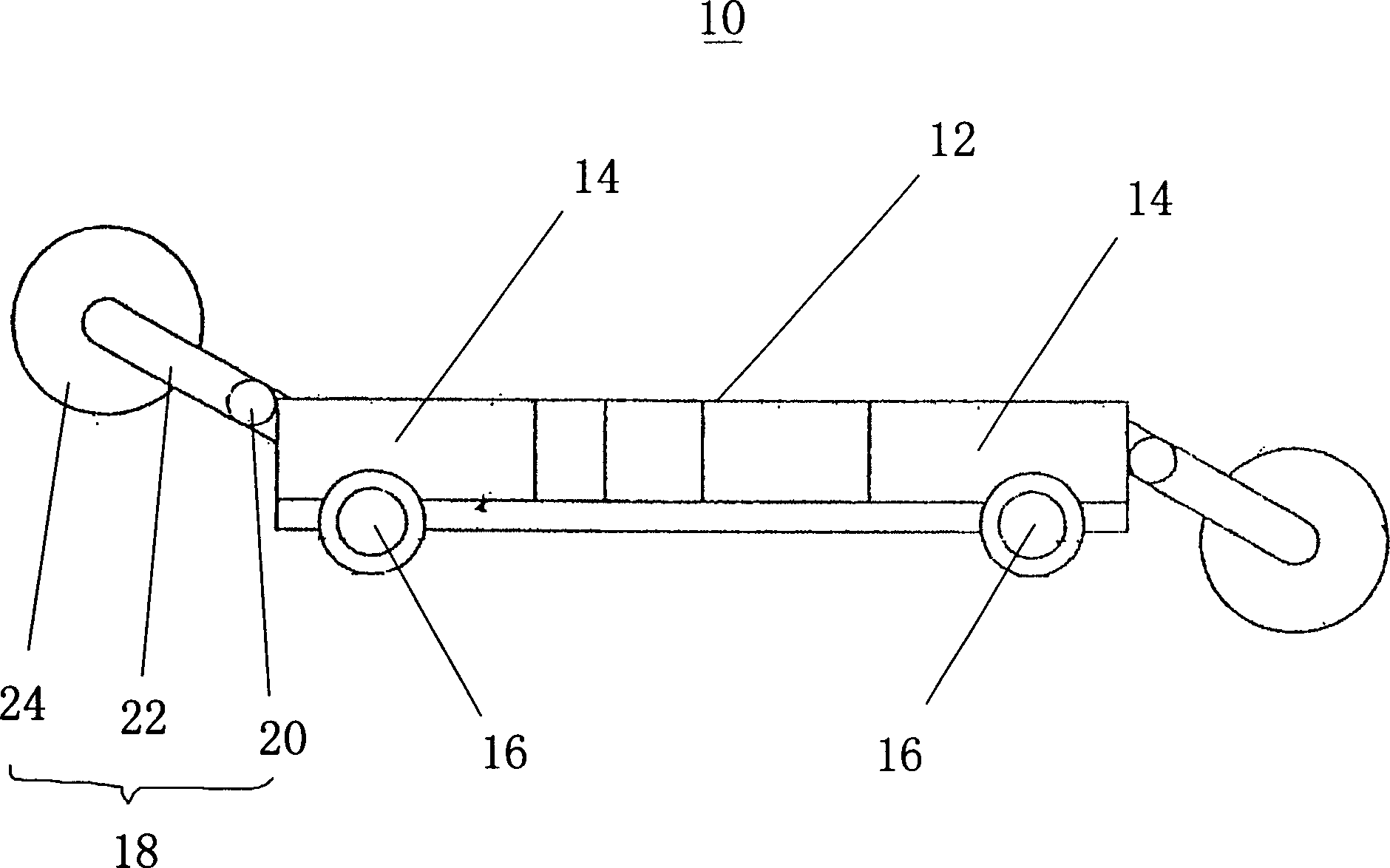

[0012] see figure 1 , discloses an electromagnetic speed-adjustable electric traction shearer 10 of the present invention, which includes a fuselage 12, two traction boxes 14 located at both ends of the fuselage, driving wheels 16 and a cutting mechanism 18. Wherein the power of the traction box 14 can be transmitted to the drive wheel 16 to make the shearer 10 move along the working face; , Two rocker arms 22 and two rollers 24.

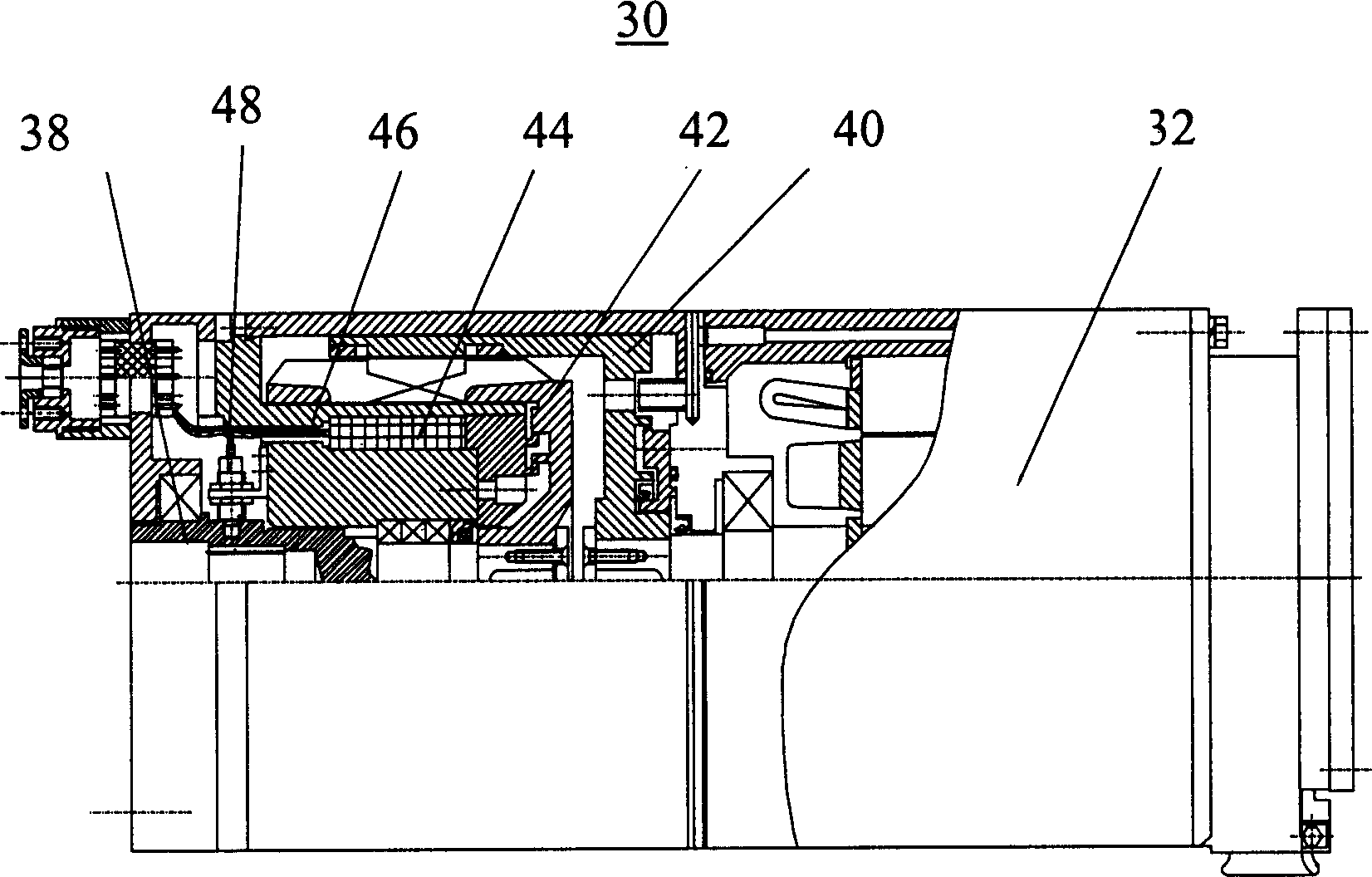

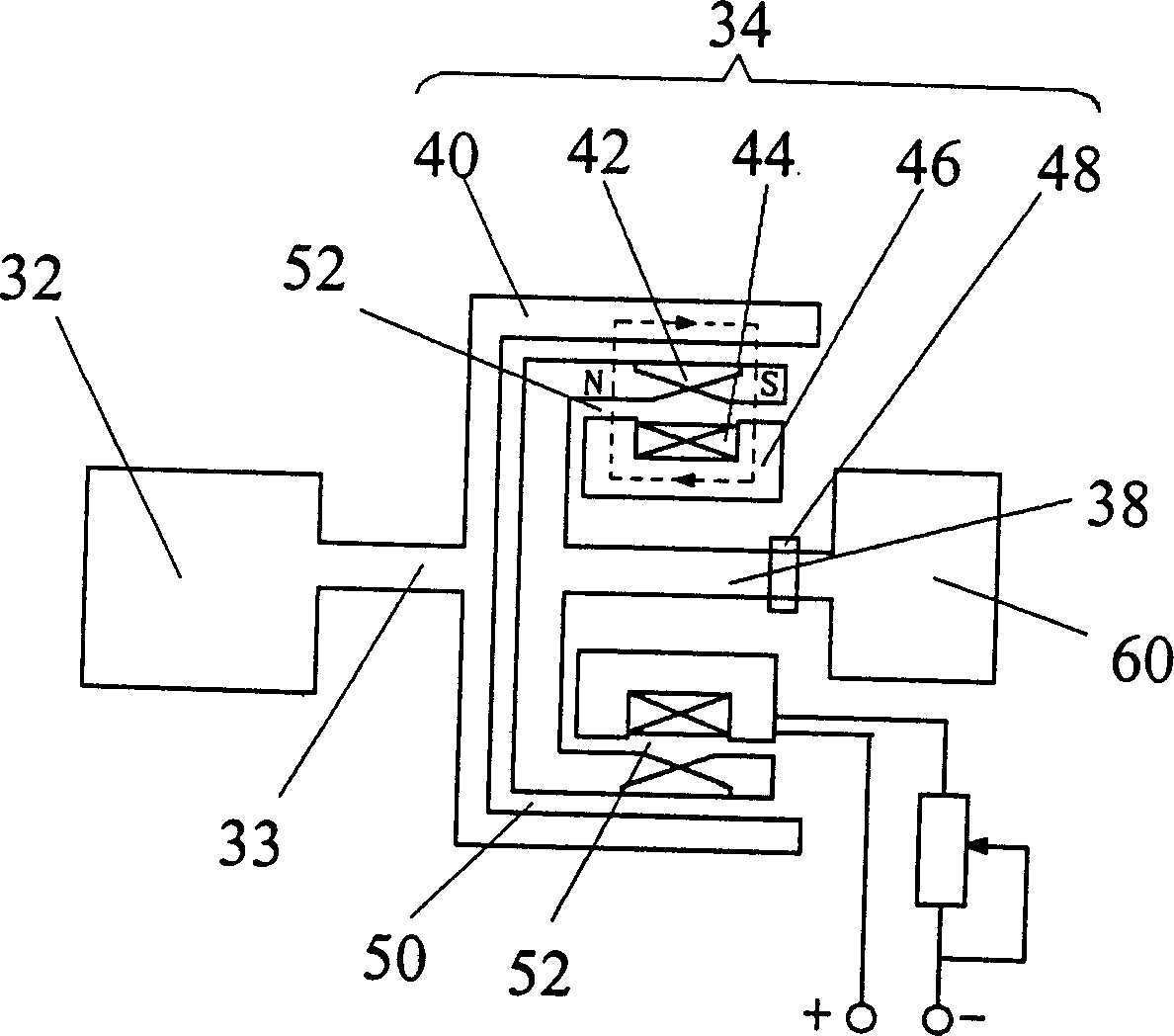

[0013] Such as figure 2 As shown, the two traction boxes 14 are respectively located at two ends of the fuselage 12, and each traction box 14 includes an electromagnetic speed-regulating motor 30, and the electromagnetic speed-regulating motor 30 includes a three-phase squirrel-cage asynchronous motor 32, an electromagnetic rotor Differential clutch 34 and speed control system 36. Wherein the three-phase squirrel-cage asynchronous motor 32 is used as the driving motor of the electromagnetic speed-regulating motor 30, and it is assembled on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com