Epoxy cast technology for high tension coil of electron accelerator

A technology of electron accelerators and high-voltage coils, applied in the direction of electrical components, accelerators, etc., can solve problems such as difficult quality assurance, low insulation strength, and easy damage on the surface, and achieve reliable performance, clear outline, and good appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

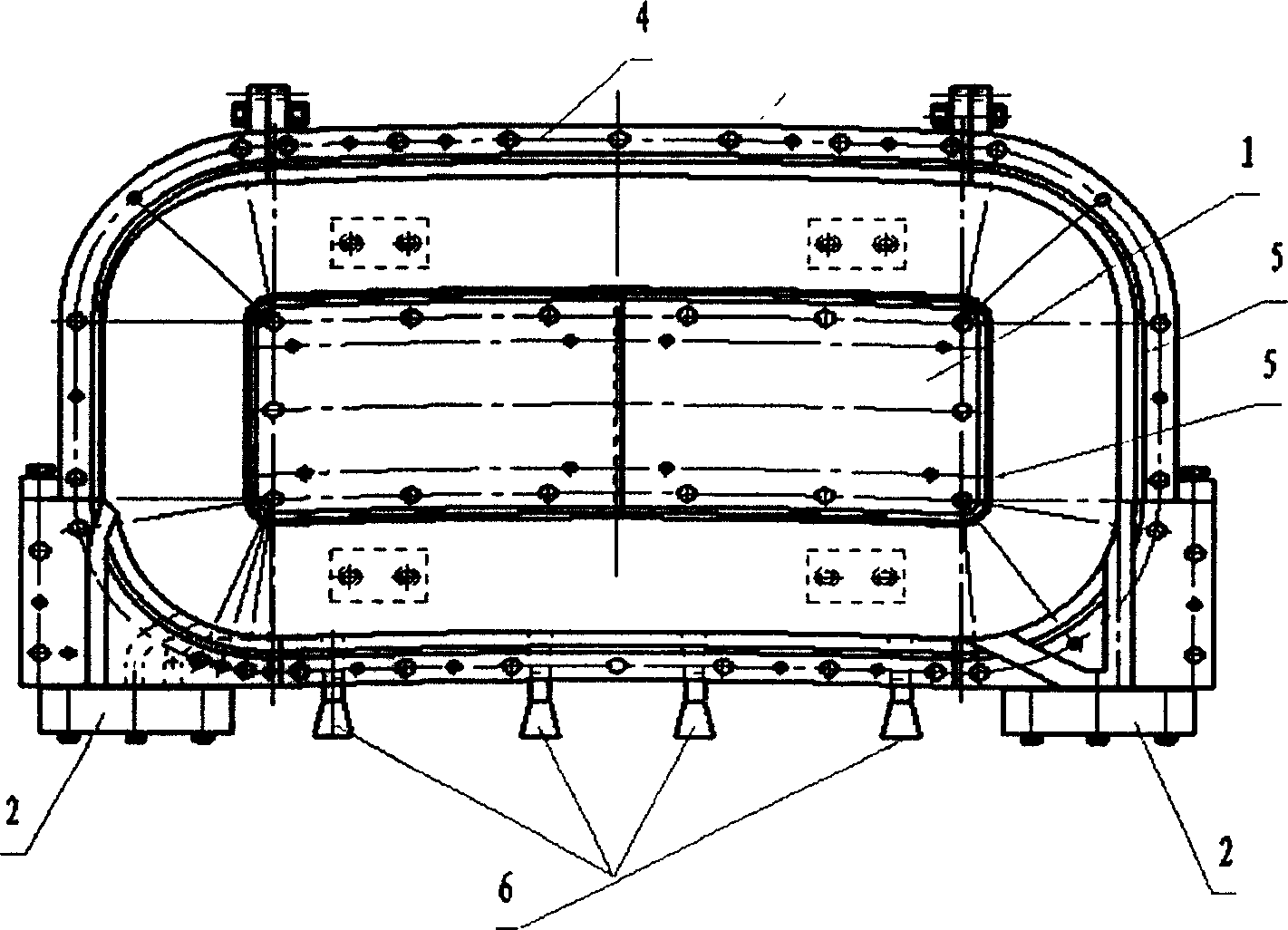

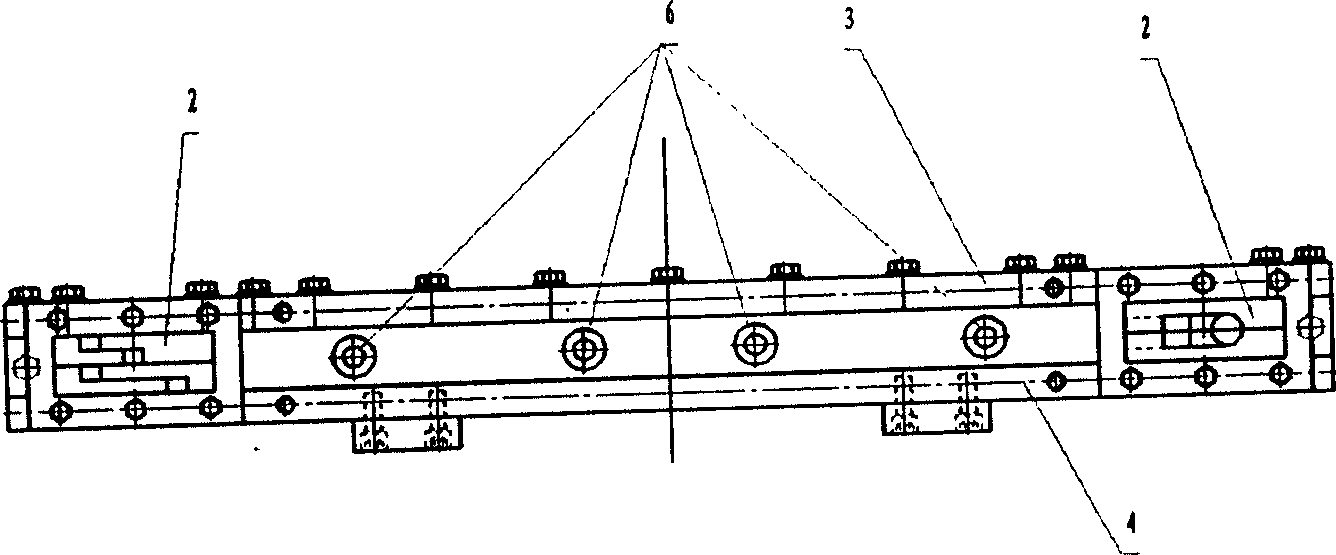

[0063] Such as figure 1 , 2 As shown, it is a schematic diagram of the structure of the epoxy casting mold for the high voltage coil of the electron accelerator, which is composed of the core 1, the gate 2, the upper template 3, the lower template 4, the sealing ring groove 5, the riser 6, and the coil epoxy filling cavity 7.

[0064] The length of the coil is in the range of 0.5-5 meters. According to the requirements of the user, a casting mold of a specification is selected, so that the core 1 is placed in the middle of the upper template 3 and the lower template 4, and the sealing ring groove 5 is placed in the core 1. Around the upper template 3 and the lower template 4, between the core 1 and the sealing ring groove 5 of the upper template 3 and the lower template 4 is the coil epoxy filling cavity 7, and the upper template 3 and the lower template 4 have pouring at both ends. Port 2, 4 risers 6 are placed between the gates 2 at both ends.

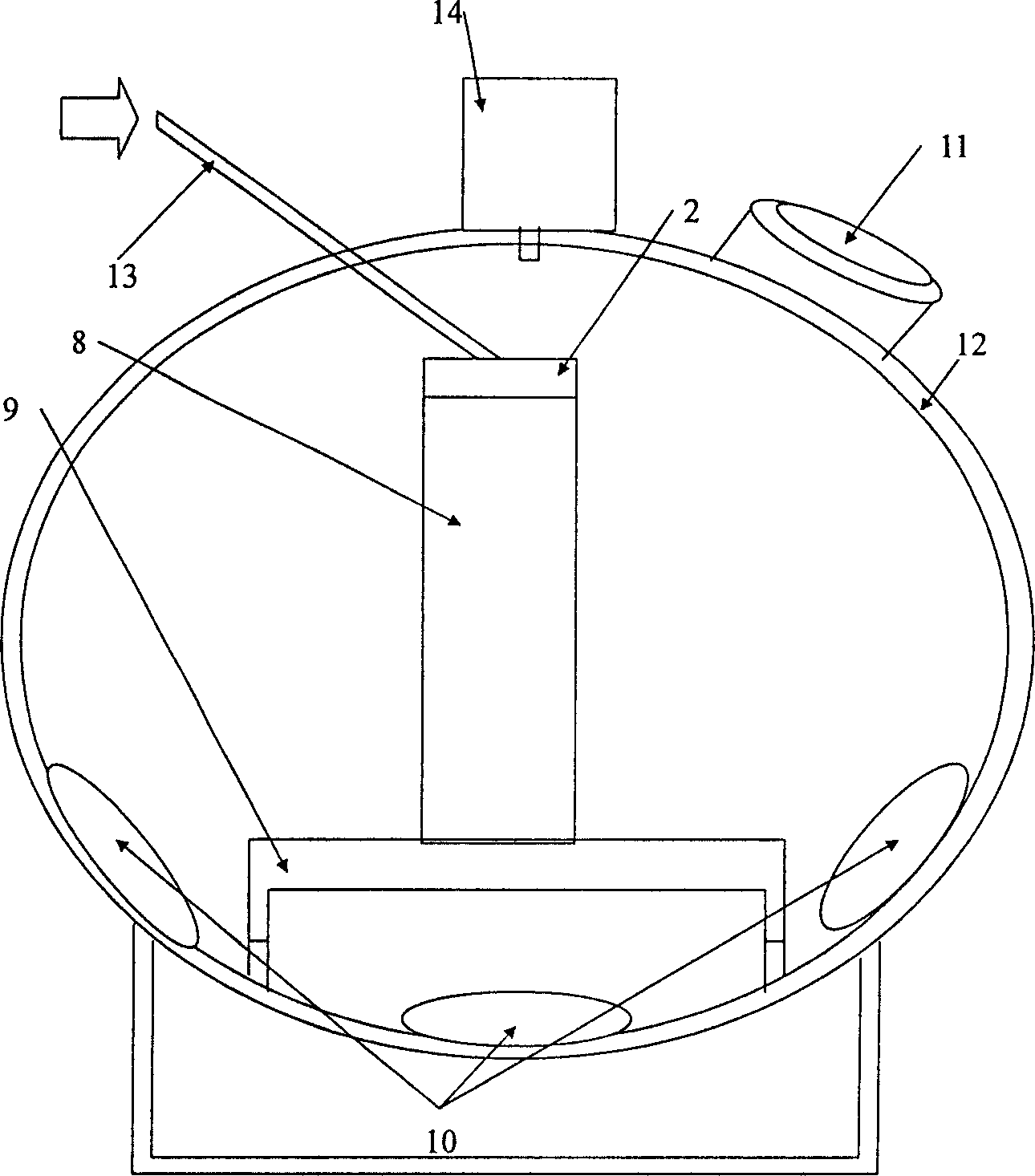

[0065] Such as image 3 Shown is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com