Photonic crystal fiber preform and photonic crystal fiber manufactured using the same

A technology of photonic crystal fiber and preform, which is applied in the direction of cladding fiber, optical components, manufacturing tools, etc., and can solve the problems that photonic crystal fiber cannot be manufactured and its characteristics are limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Detailed descriptions of known functions and constructions contained herein will be omitted for clarity and conciseness.

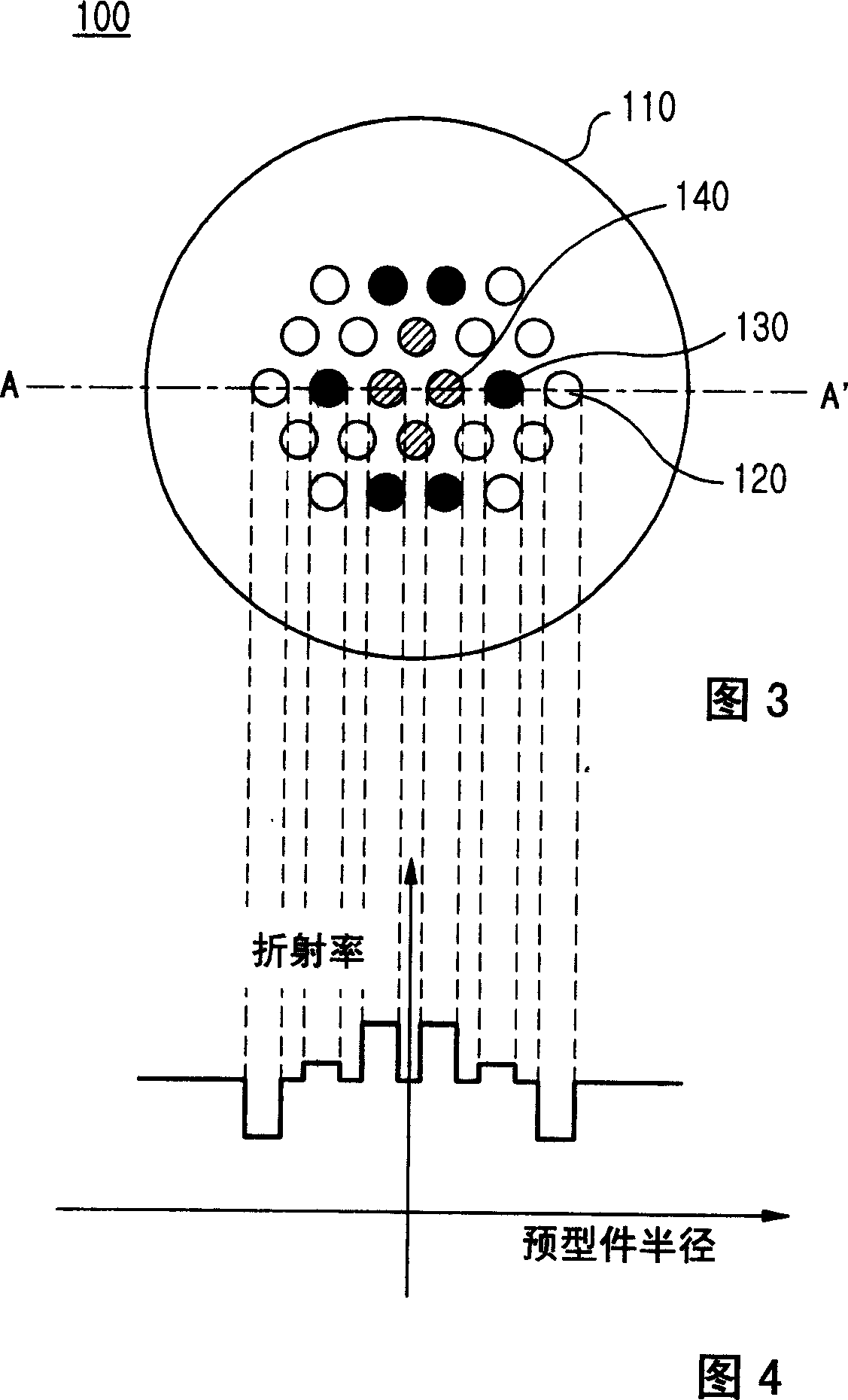

[0025] Fig. 3 illustrates, by way of an illustrative and non-limiting example, a cross-sectional view of a photonic crystal fiber preform 100 according to a first preferred embodiment of the present invention.

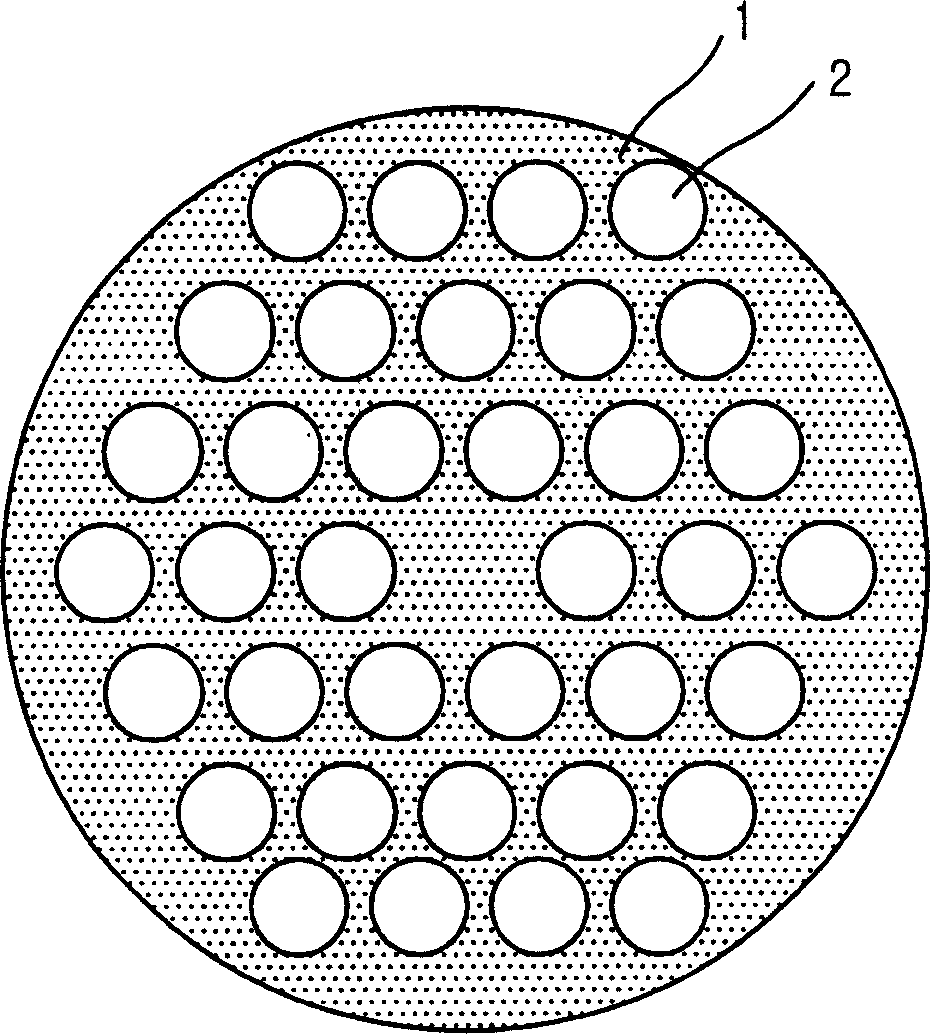

[0026] The photonic crystal fiber preform 100 is made of a rod-shaped base 110 through which a plurality of holes are longitudinally formed in an optical lattice structure. Each of the holes has a circular cross section, and a diameter of each hole is smaller than that of the rod-shaped base 110 . The holes are uniformly separated from each other to form a hexagonal pattern, and are respectively filled with materials 120, 130 and 140 having at least two different refractive indices. The refractive index profile of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com