Line scanning examination method for inclined transportation

An inspection method and line scanning technology, applied in the direction of material analysis, instruments, and measuring devices by optical means, can solve the problems of severe vibration, no development, and it is difficult to set the air volume of the blower on the glass substrate, so as to improve the ability, Increased throughput and reduced effectiveness of particle contamination inspection tasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, specific embodiments of the present invention will be described with reference to the drawings.

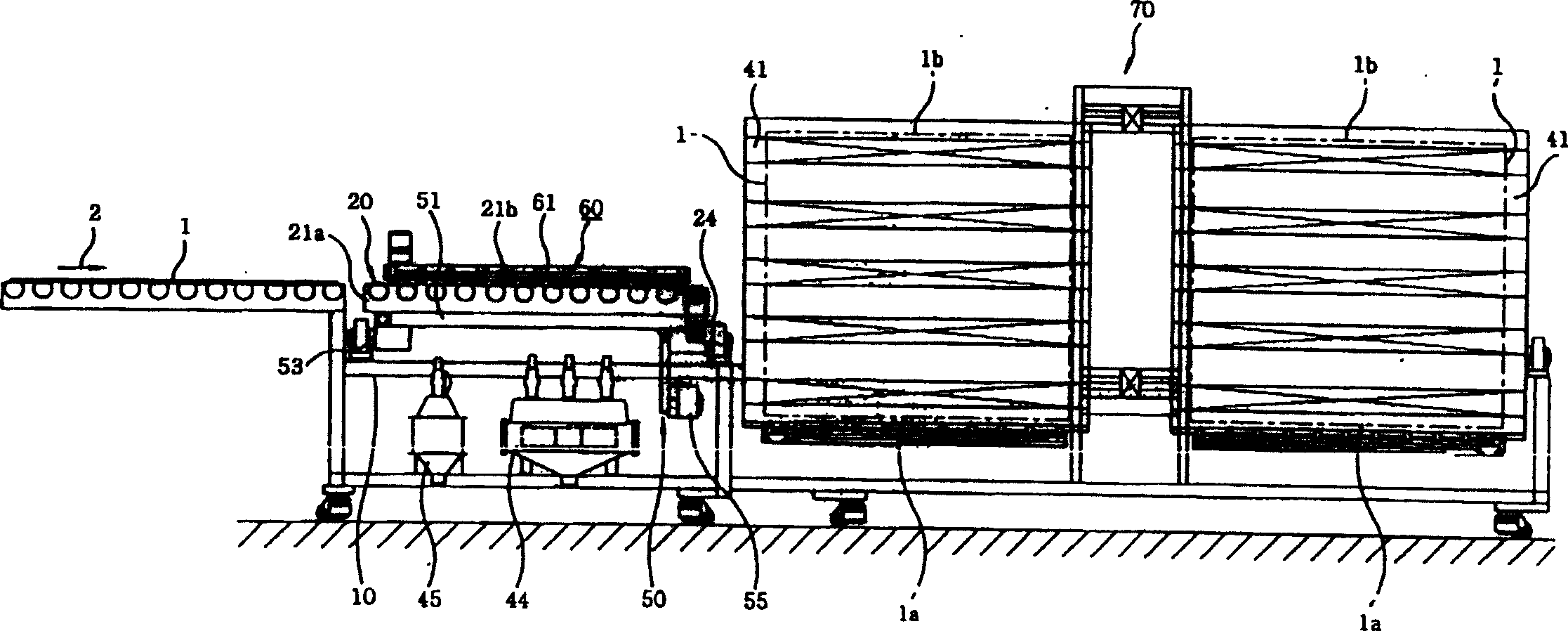

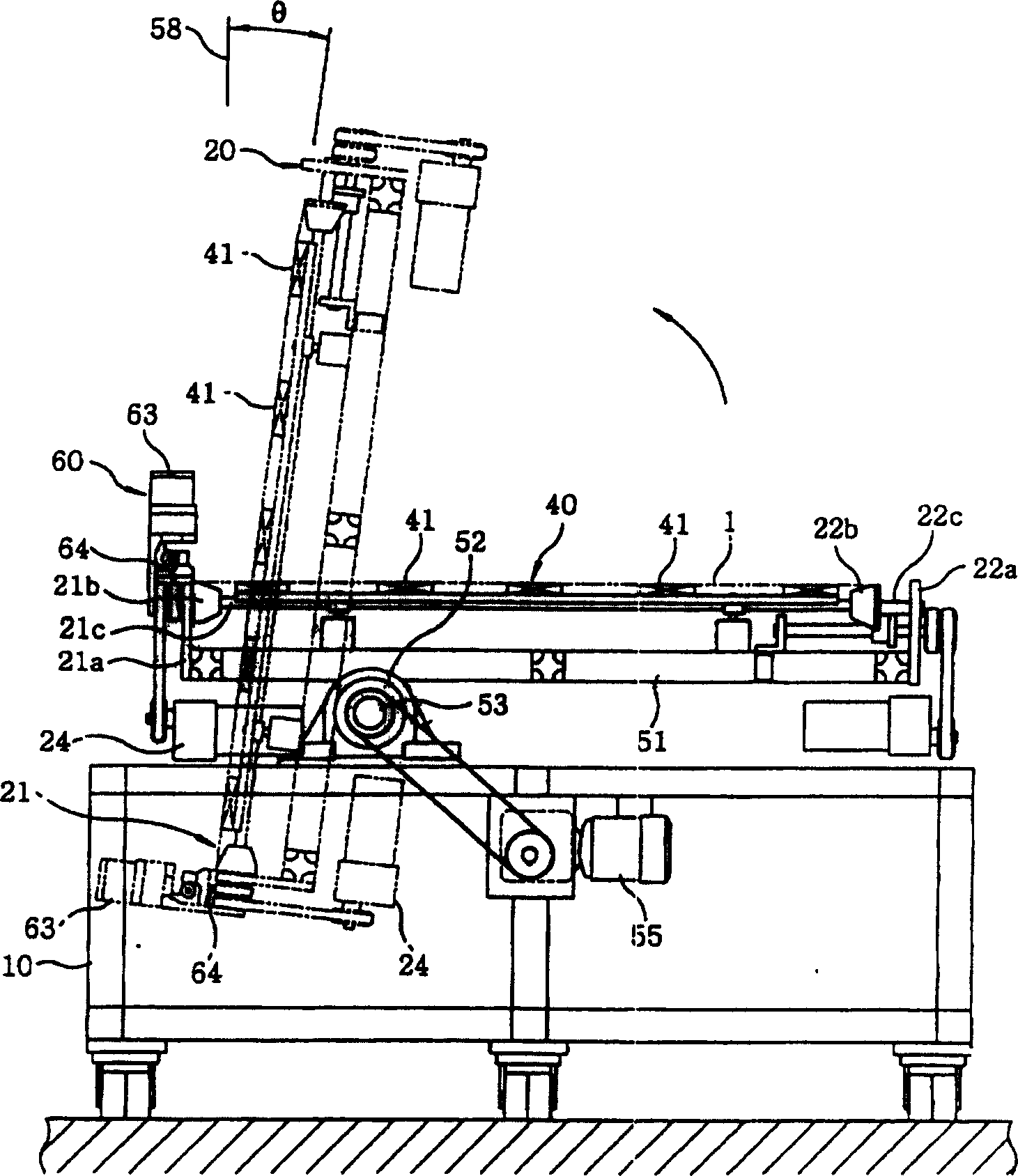

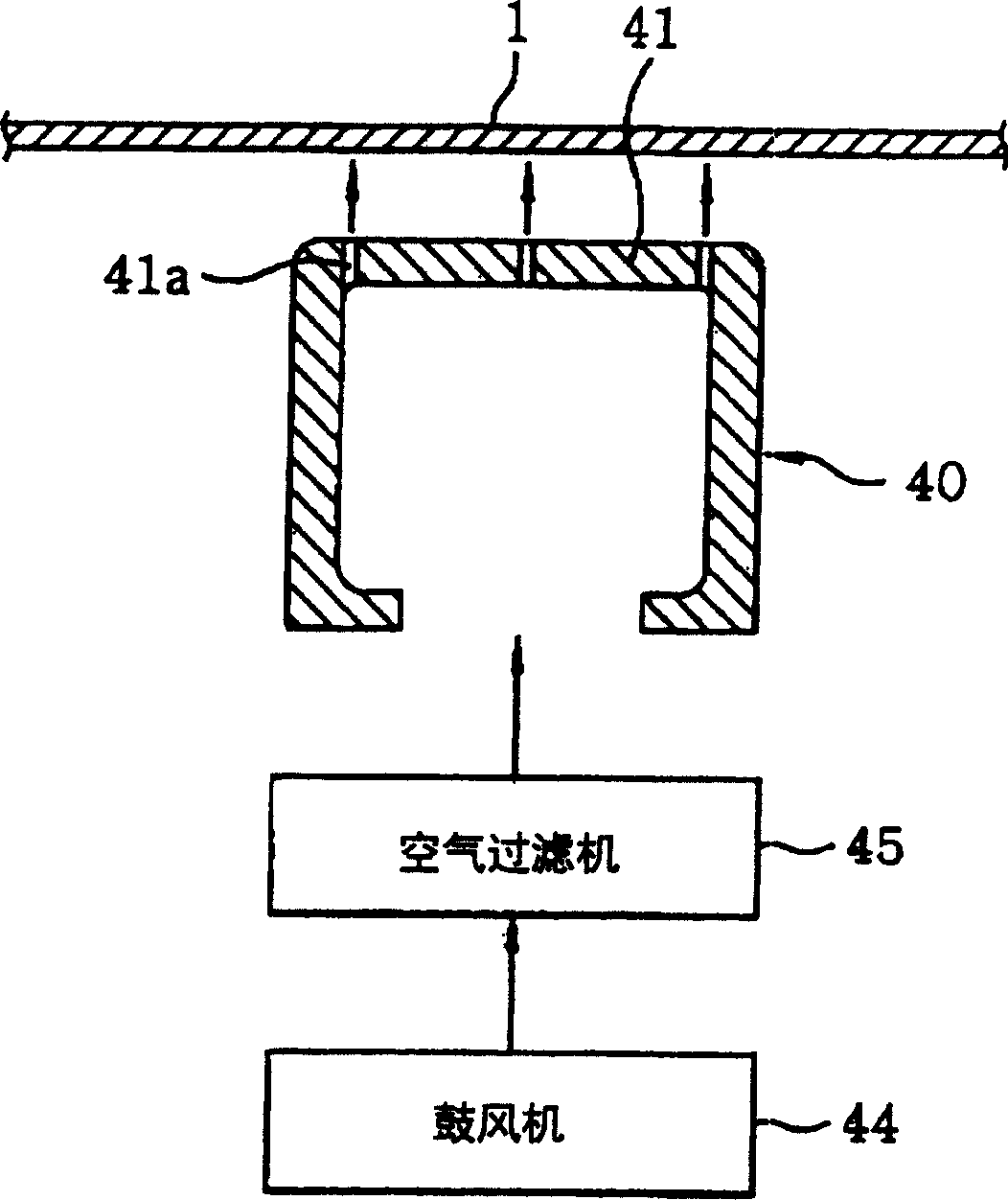

[0025] figure 1 It is a front view showing the basic structure of the system for implementing the scanning inspection method of the inclined conveying line of the present invention, figure 2 is a front view showing the tilting system. As shown in the figure, the line scanning inspection system in the inclined conveyance of a preferred embodiment of the present invention has a horizontal conveying device 20 installed on the conveyor main body 10 for supporting both sides of the glass substrate 1 for horizontal conveying, a spray nozzle The air floating device 40 ( figure 2 ), the tilting device 50 for tilting the glass substrate 1 placed on the horizontal transfer device 20 and for tilting the horizontal transfer device 20 and the air floating device 40 , and for tilting the glass substrate 1 together with the tilting device 50 The lower part of the glass substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com