Methods of manufacturing wiring pattern, methods of manufacturing organic electro luminescent element

A manufacturing method and thin-film pattern technology, which is applied in the manufacture of electroluminescent light sources, discharge tubes/lamps, ships or lead-in wires, etc., can solve the problem of uneven film thickness, time-consuming, and uneven light emission of thin-film patterns, etc. problem, achieve the effect of reducing uneven lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

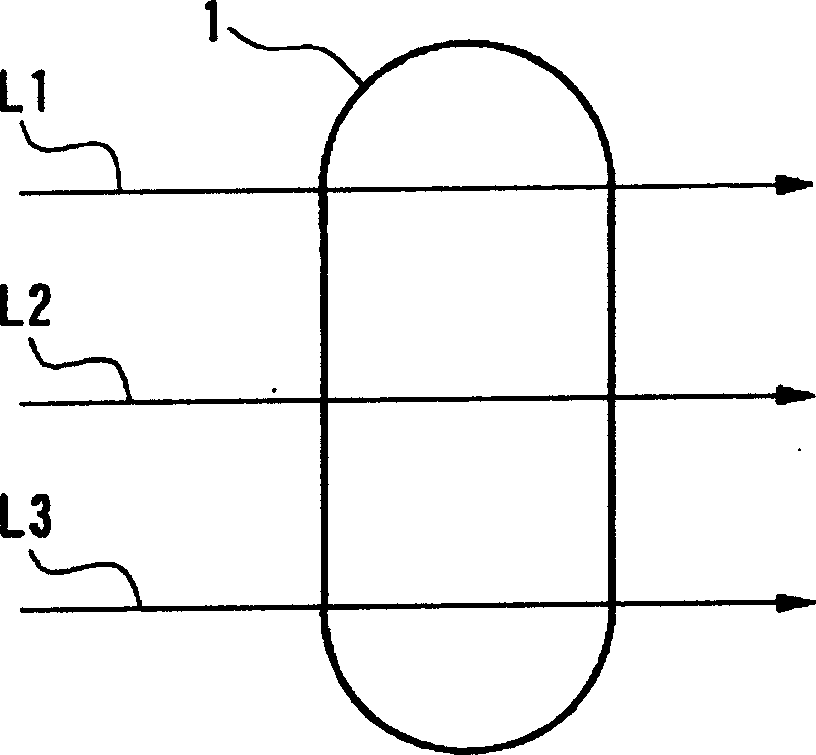

[0073] figure 1 It is an explanatory drawing showing the manufacturing method of the thin film pattern in Embodiment 1 of this invention. A pixel region 1 is formed on a substrate. It is preferable to provide rib-shaped partition walls (banks) on the outer periphery of the pixel area 1 . The pixel area 1 takes a longitudinal shape, with a long axis passing through the center of the pixel area 1 and running vertically through the pixel area 1 , and a short axis passing through the center of the pixel area 1 and running across the pixel area 1 . Furthermore, the shape of the pixel area 1 may be rectangular, elliptical, or the like.

[0074] In the pixel area 1, a liquid material is applied by ejecting droplets. For example, when the pixel formed in the pixel region 1 is an organic EL element, the liquid material is a material composed of a material for forming a hole injection layer or a light emitting layer and a solvent. figure 1The illustrated scanning lines L1 , L2 , a...

Embodiment approach 2

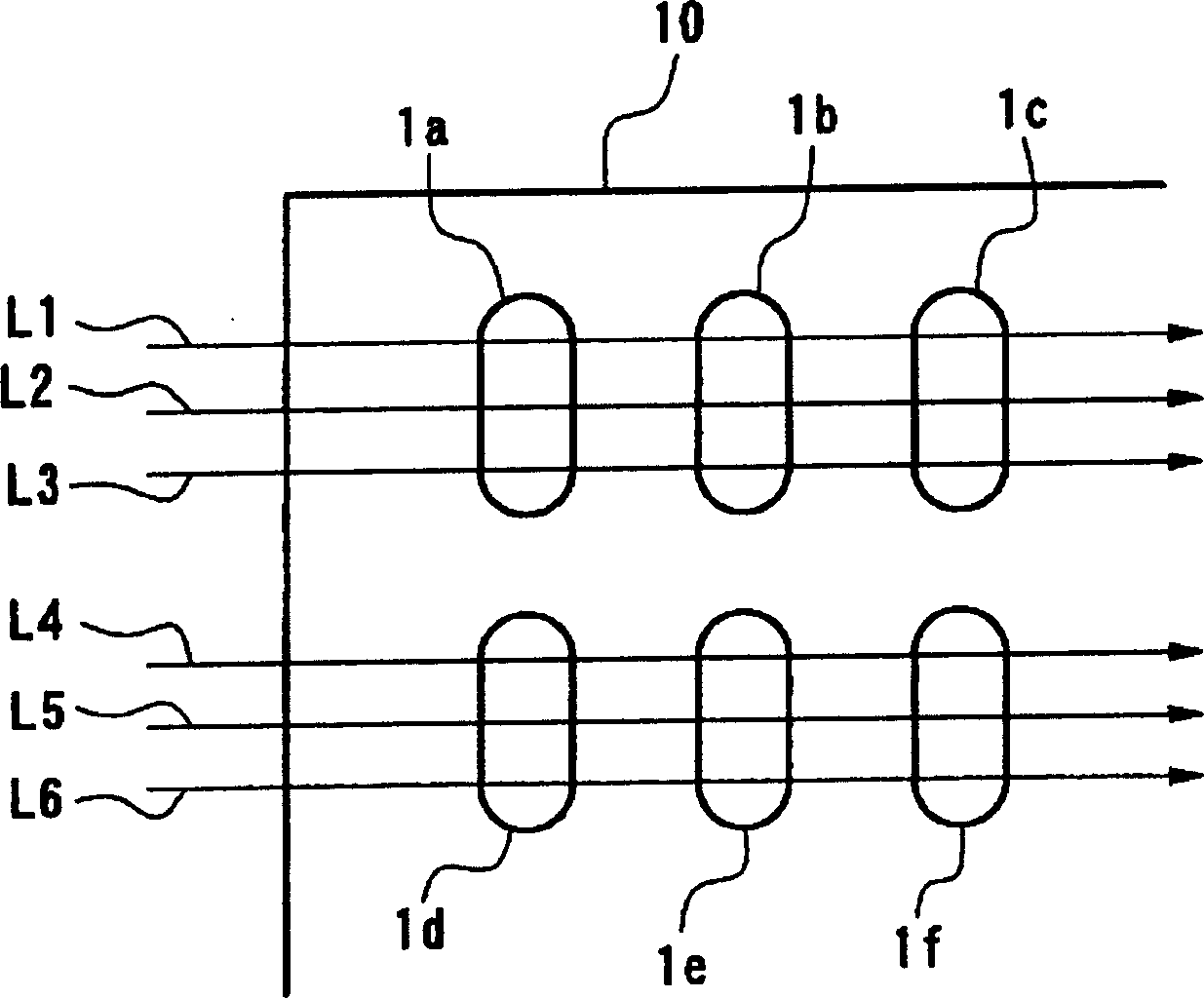

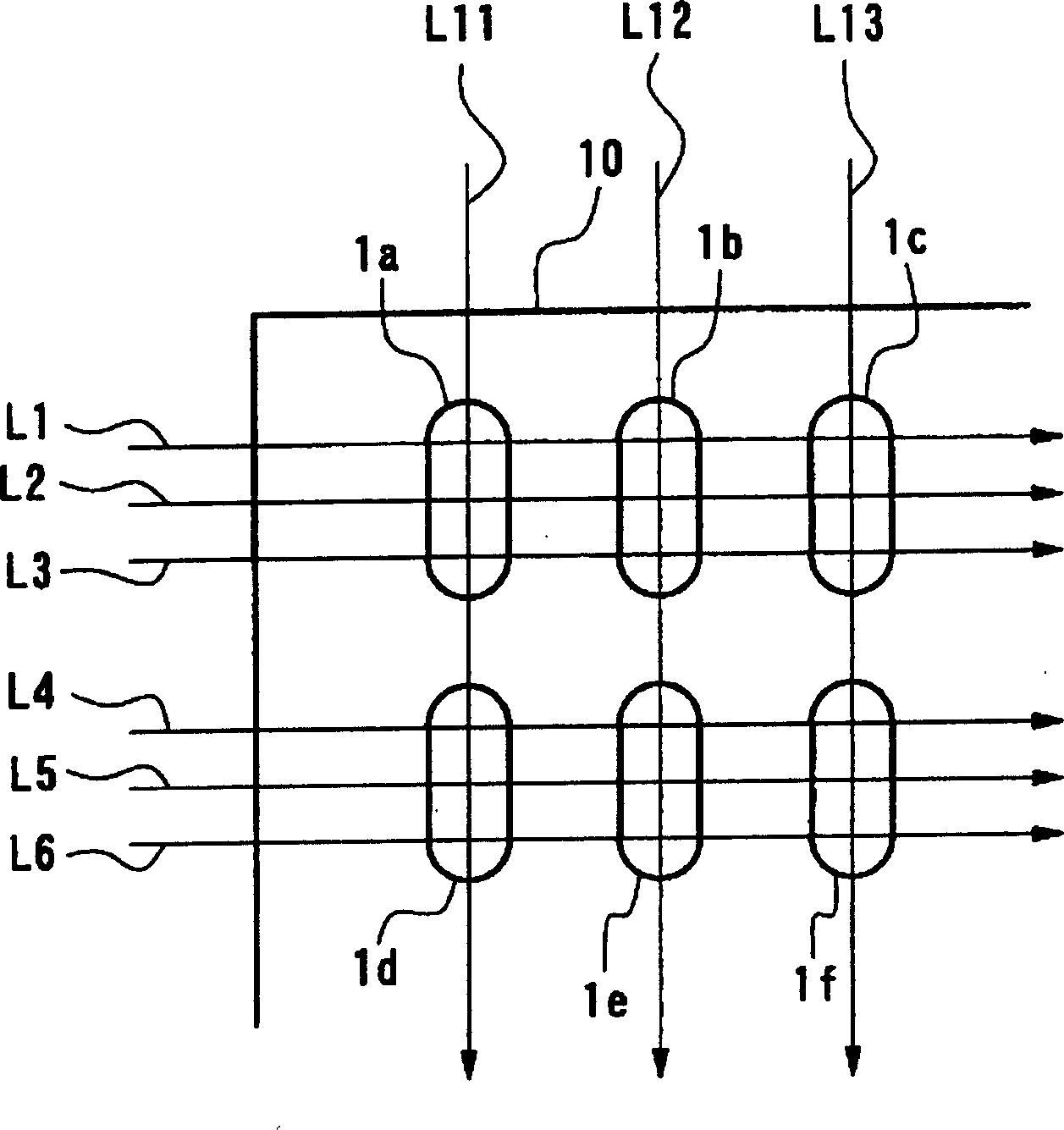

[0094] Refer below image 3 Embodiment 2 of the present invention will be described. image 3 It is an explanatory drawing showing the manufacturing method of the thin film pattern in Embodiment 2 of this invention. The difference between this embodiment and the above-mentioned Embodiment 1 is that in this embodiment, not only the scanning lines L1, L2, L3, L4, L5, L6, and scanning lines L11, L12, L13 are set along the long-axis directions of the pixel regions 1a, 1b, 1c, 1d, 1e, and 1f.

[0095] Specifically, first, a plurality of pixel regions 1 a , 1 b , 1 c , 1 d , 1 e , and 1 f are formed on the upper surface of the substrate 10 . It is preferable to provide rib-shaped partitions (dams) on the outer peripheries of the respective pixel regions 1a, 1b, 1c, 1d, 1e, and 1f.

[0096] Thereafter, for the pixel regions 1a, 1b, 1c formed as pixels of the first row, and figure 2 The method shown is the same, the scanning lines L1, L2, L3 are set, and the ink nozzles are scann...

Embodiment approach 3

[0101] Refer below Figure 4 and Figure 5 Embodiment 3 of the present invention will be described. Figure 4 It is an explanatory drawing showing the manufacturing method of the thin film pattern in Embodiment 3 of this invention. In this embodiment, a droplet ejection device in which a plurality of ink nozzles 21 a , 21 b , and 21 c are provided on a nozzle head 20 is used. The respective ink nozzles 21 a , 21 b , and 21 c may be arranged at predetermined intervals on a predetermined straight line on the nozzle head 20 .

[0102] With respect to the pixel region 1 , a plurality of scanning lines L1 , L2 , and L3 are set parallel to the minor axis of the pixel region 1 . In addition, the nozzle head 20 is moved in the minor axis direction of the pixel area 1 so that the ink nozzle 21a moves on the scanning line L1, the ink nozzle 21b moves on the scanning line L2, and the ink nozzle 21c moves on the scanning line L3.

[0103]Here, in such a manner that the straight lines ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com