Optical fiber having a lower bending loss

A technology of optical fiber and optical fiber ribbon, applied in the direction of multi-layer core/clad optical fiber, glass optical fiber, clad optical fiber, etc., which can solve the problems of increased transmission loss and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] Hereinafter, examples of the present embodiment are described.

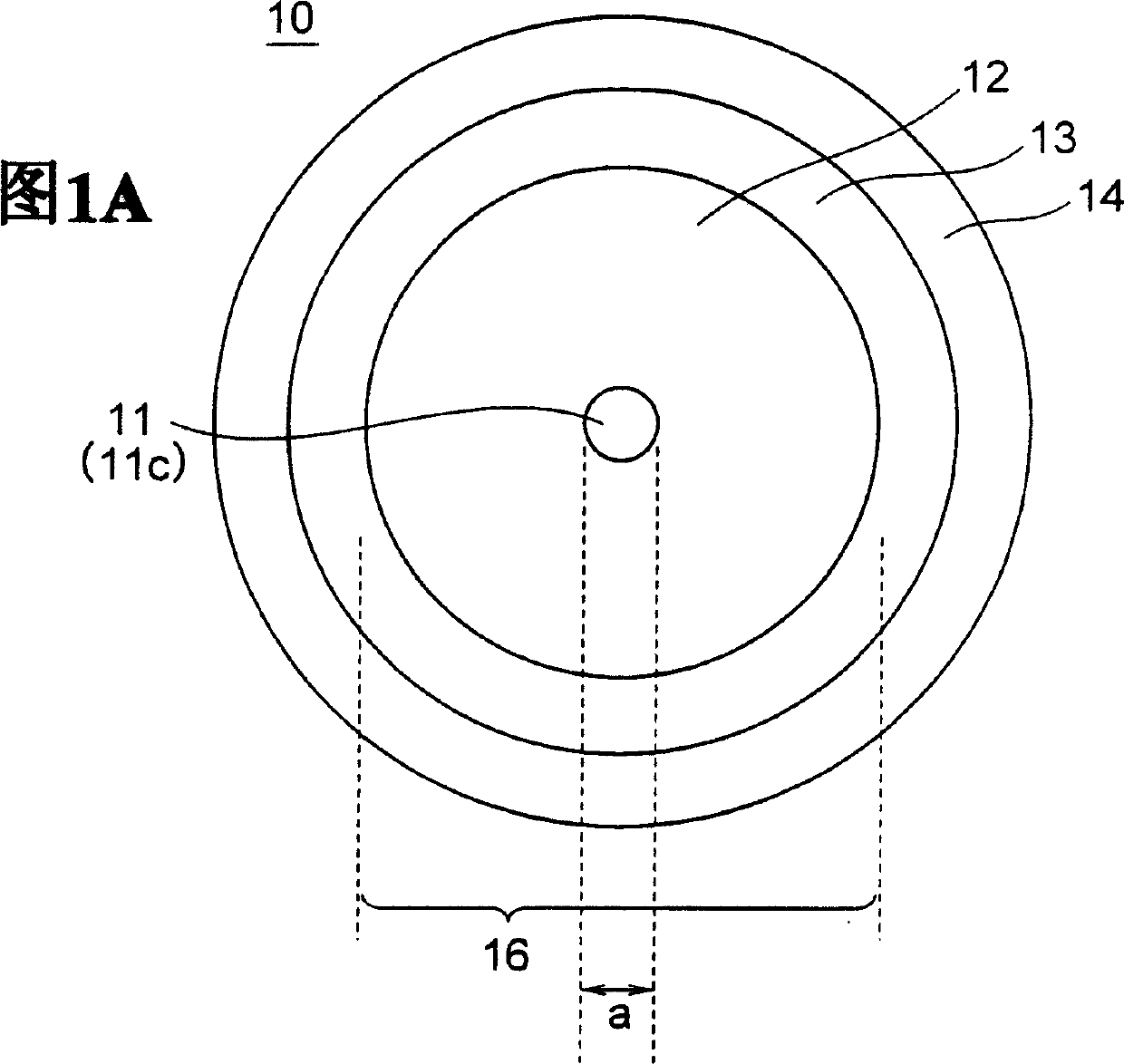

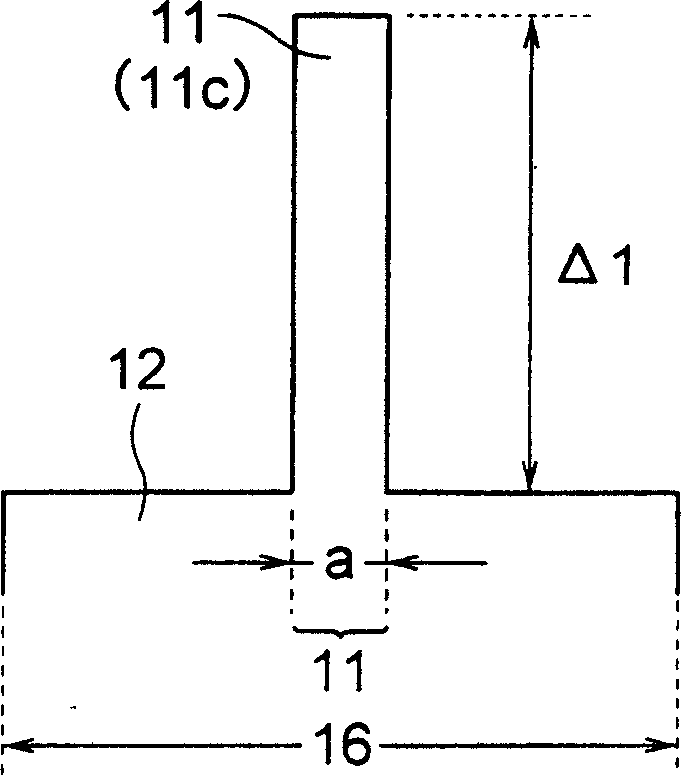

[0050] To produce glass fiber 16 having the refractive index profile shown in the graph of Figure IB, an optical fiber preform is first produced. In the process of manufacturing an optical fiber preform, a porous core powder (soot) including a first core and a partial cladding is formed by vapor axial deposition (VAD). The resulting porous preform is dehydrated and vitrified to obtain a glass core rod.

[0051] It should be pointed out here that in order to be suitable for WDM transmission in the wavelength range of 1285~1625nm, the absorption loss of OH group at 1383nm wavelength needs to be reduced as much as possible, and the Increased absorption loss. Therefore, it is required that OH groups are not mixed into the optical fiber during the manufacturing process.

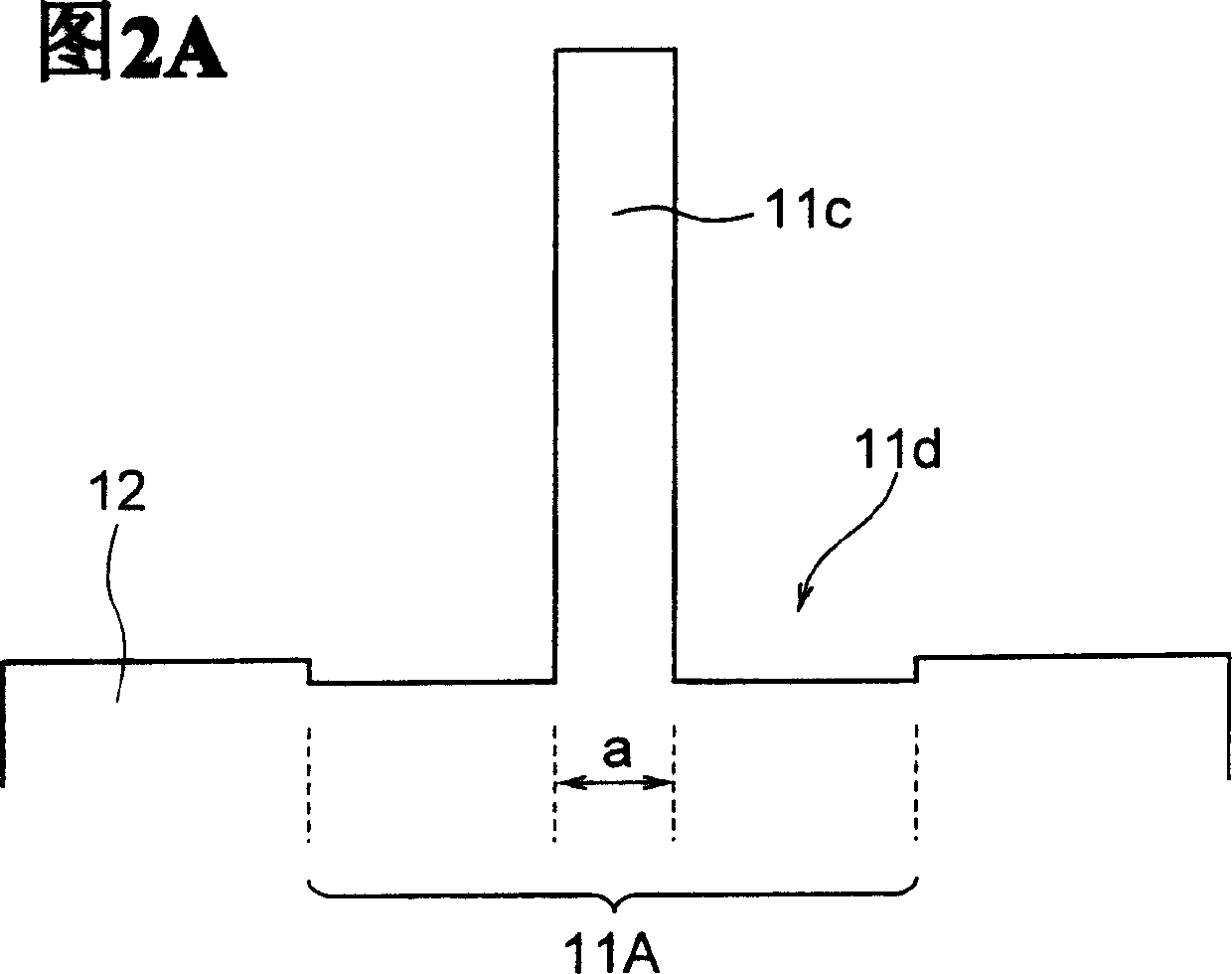

[0052] As mentioned above, the process generally used here is to manufacture the first core 11c and the first core 11c having a diameter a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com