Wastewater treating apparatus

A sewage treatment device and water treatment technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, aerobic process treatment, etc., can solve the problems of increasing treatment costs, large-scale treatment equipment, etc., and achieve low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

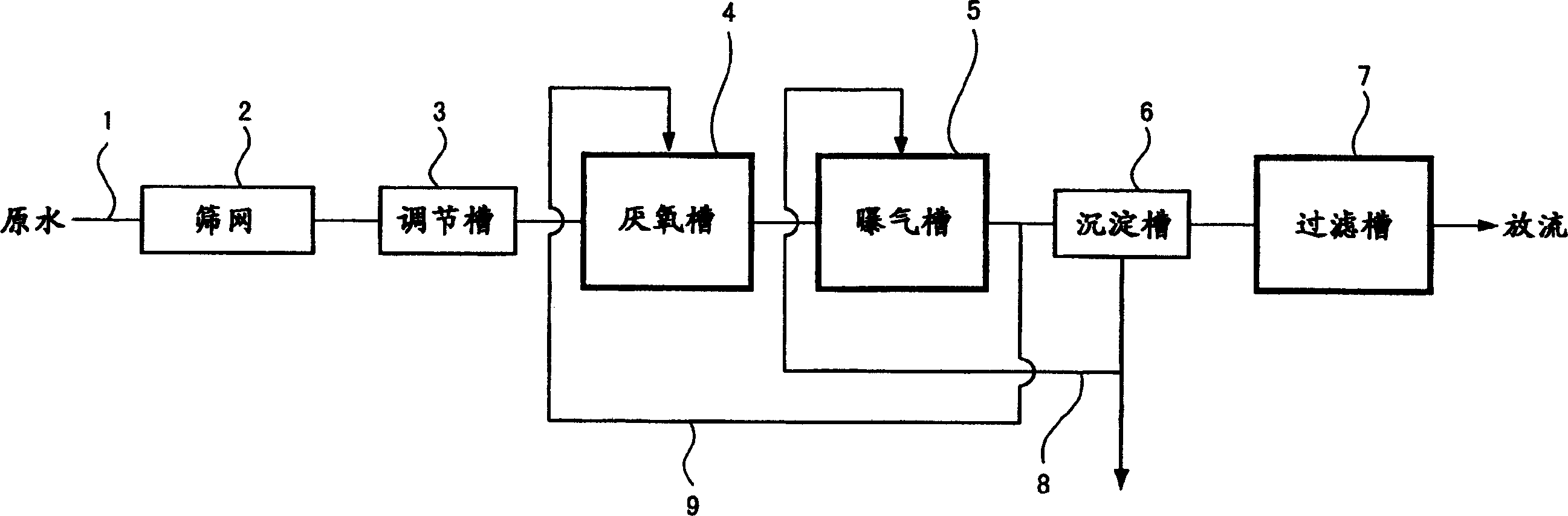

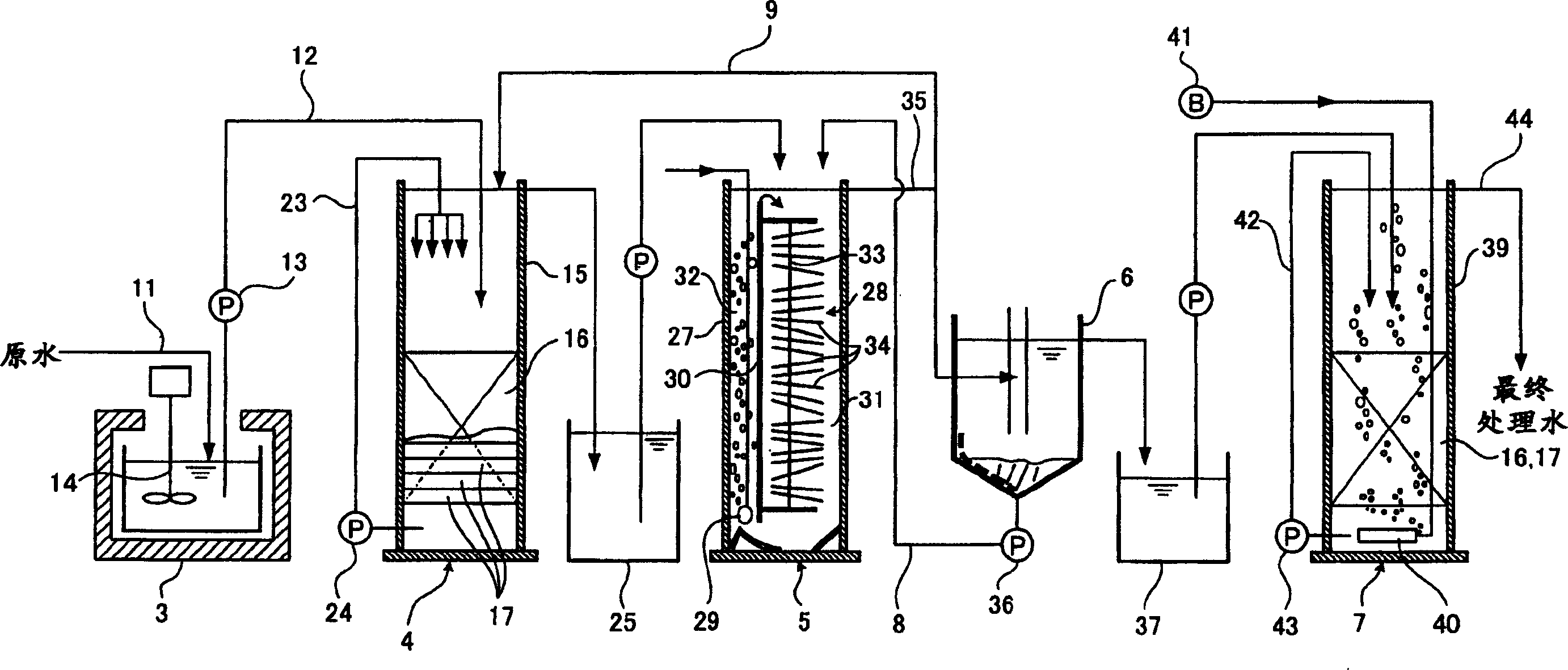

[0070] As described in specific examples, in figure 1 and figure 2 In the device, the anaerobic tank 4 is used to perform treatment, and the organic compound with a high volume load can be converted into an organic acid. For example, for starch manufacturing process series wastewater, the volume load at BOD is 7.8kg / m 3 · At time d, when the anaerobic tank 4 was used for 5.3 hours, the BOD value decreased to 1340 mg / L. At this point, volatile fatty acids (VFA) reached a level of 857 mg / L, with 46.4% acetic acid, 27.7% propionic acid, 16.0% butyric acid, and 9.9% valerenic acid. Therefore, the aerobic treatment in the post-stage aeration tank 5 is performed very easily and stably.

[0071] so, in figure 1 and figure 2 In the device, it is possible to process organic compounds with high volume load. As a volume load, for example, the anaerobic tank 4 can reach 5-20kg / m 3 d. The aeration tank 5 is 2~8kg / m 3 d. The filter tank 7 is 0.5~1.5kg / m 3 d, and in the previous st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com