Reacting polymer cement waterproof coating and preparing method thereof

A waterproof coating, reactive technology, applied in cement coatings, antifouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor water resistance, cracking, and non-drying, and achieve broad market prospects and comprehensive performance The effect of superior, excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment.

[0027] Make 200 kilograms of products of the present invention, wherein organic components are: 93 kilograms of polyurethane emulsions, 5 kilograms of phthalic acid plasticizers, 2 kilograms of organosilicon defoamers; inorganic components are: 70 kilograms of white cement, light 30 kg of calcium carbonate, prepared according to their respective weight ratios, then put the organic components, inorganic components and water into the mixing tank according to the weight ratio of 1:1:0.4, and then mix them evenly Put into use.

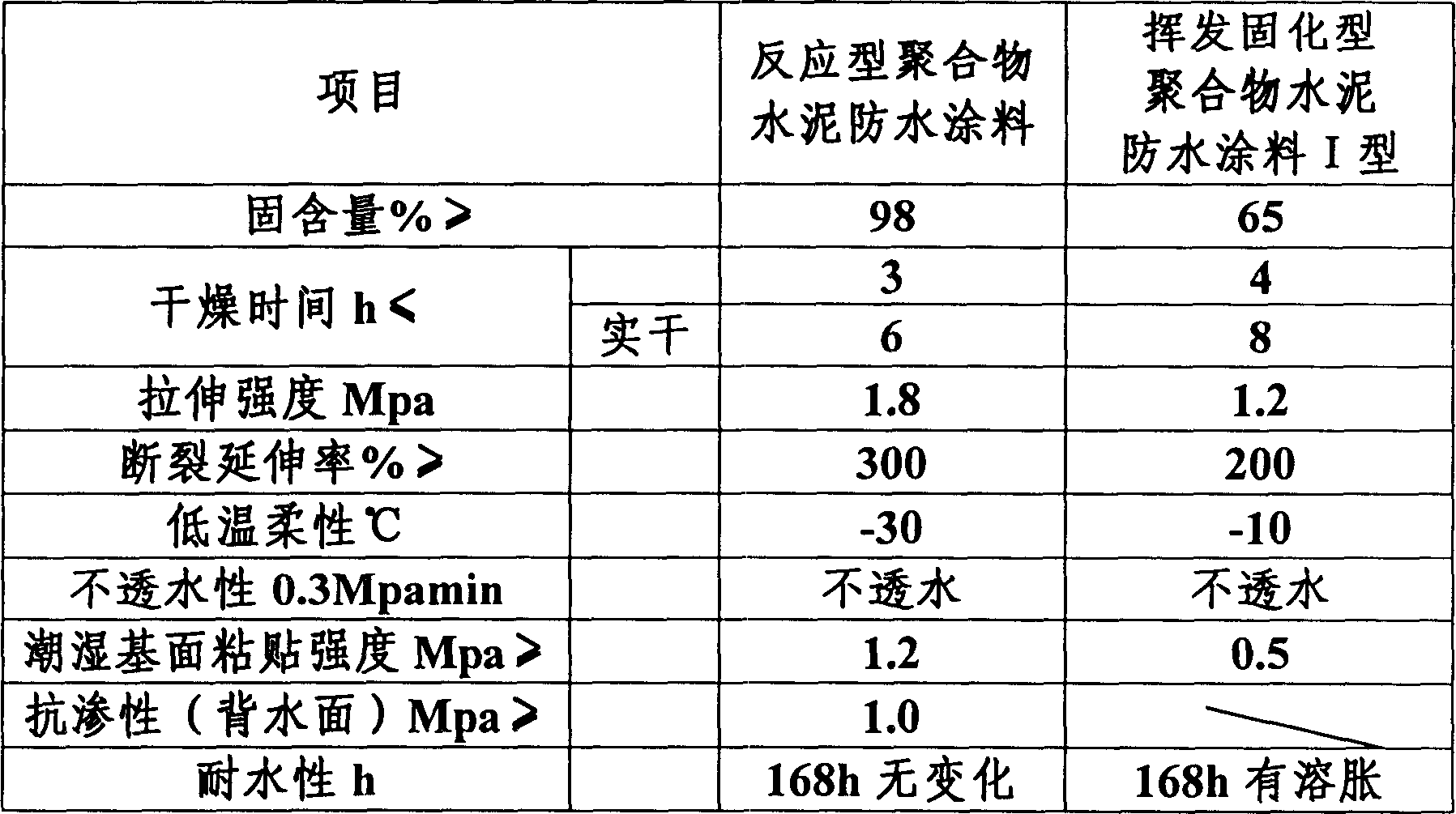

[0028] The following table is the result of comparing this product with volatilization-curing polymer cement waterproof coating type I under the same conditions after actual use.

[0029]

[0030] Among them, the industry standard for volatilization-curing polymer cement waterproof coating is: JC / T894-2001. It can be concluded from the above table that compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com