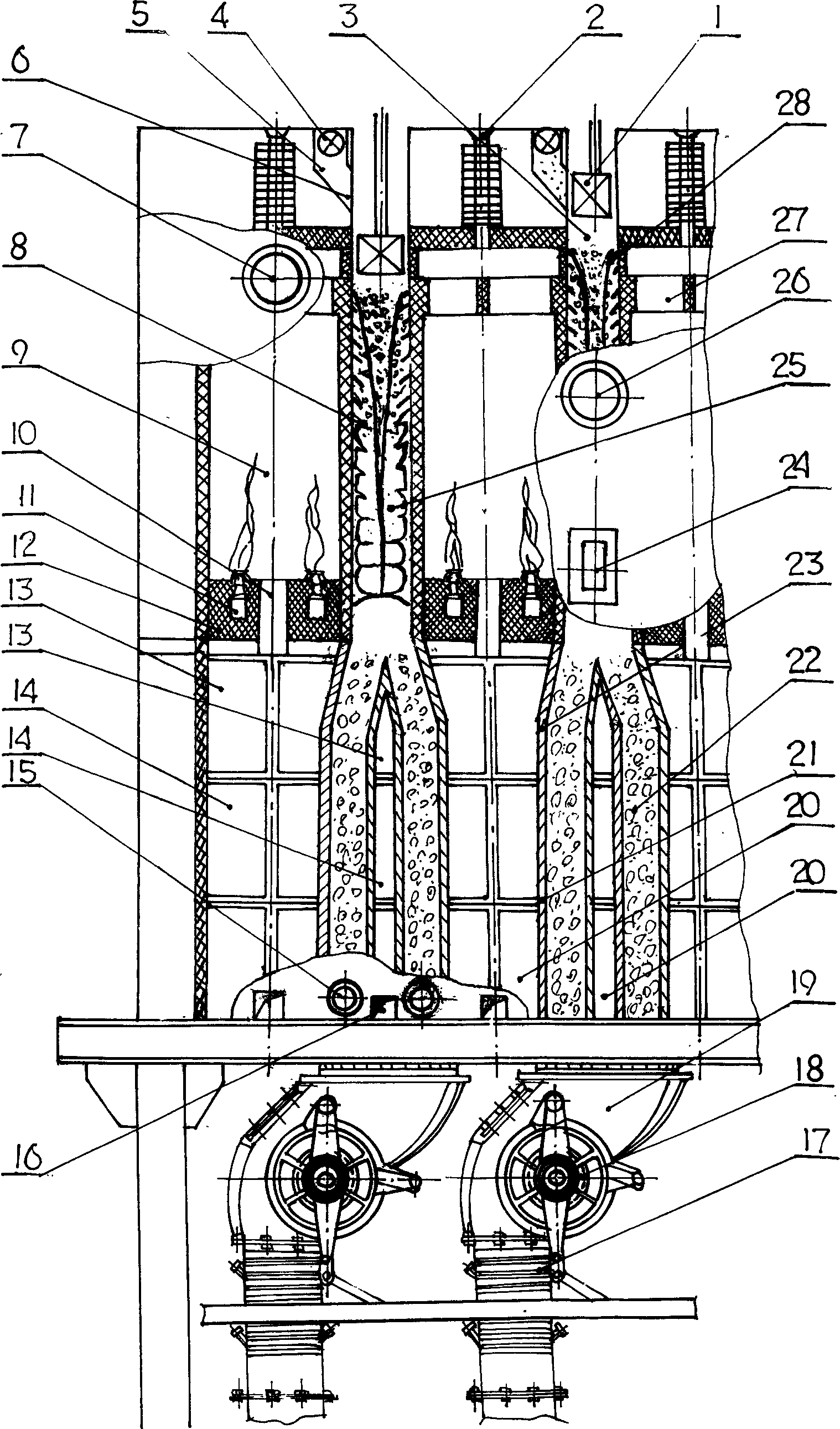

Vertical automatic cokery with cold loading and cold discharge

A vertical, fully automatic technology, applied in coke ovens with vertical carbonization chambers, coke ovens, petroleum industries, etc., can solve the problems of non-recovery of sensible heat of hot gas, occupying a large space, and increasing the amount of bricks used. Solve the effect of environmental protection and investment and economic benefits, high labor productivity, and reducing heat dissipation of the furnace body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The furnace top of this invention is provided with side material distributing trough 5, fire adjusting hole 2, starts distributor 4 when charging coal, after coal material is covered with side material distributor 5 by distributor 4, shuts down distributor 4, this moment presses coal pushes The coke plate 1 is blocked at the discharge port 6 of the side distributing chute 5, and the coke plate 1 is lifted and pressed by the hydraulic cylinder, and the coal in the side distributing chute 5 is immediately unloaded into the coal loading section 3 at the top of the carbonization chamber 8, and coal pressing is required When pushing coke, the coal-pressed coke plate 1 is pushed downward by the hydraulic cylinder. After reaching a certain stroke and pressure, the coal-pressed coke plate 1 is lifted up, and then the discharge port 6 of the upper side distribution chute 5 is blocked, that is, Complete a cycle. The coal material enters the rapid heating section 28 from the coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com