Low voltage micro liquid drop control device

A technology for controlling devices and micro-droplets, which is applied in the direction of instruments and analytical materials, can solve the problems of unfavorable device miniaturization and high-density integration, large control electrode size, and low droplet moving speed, so as to achieve the driving speed of droplets Fast, small droplet size and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The low-voltage micro-droplet control device proposed by the present invention is described in detail in conjunction with the accompanying drawings and embodiments as follows:

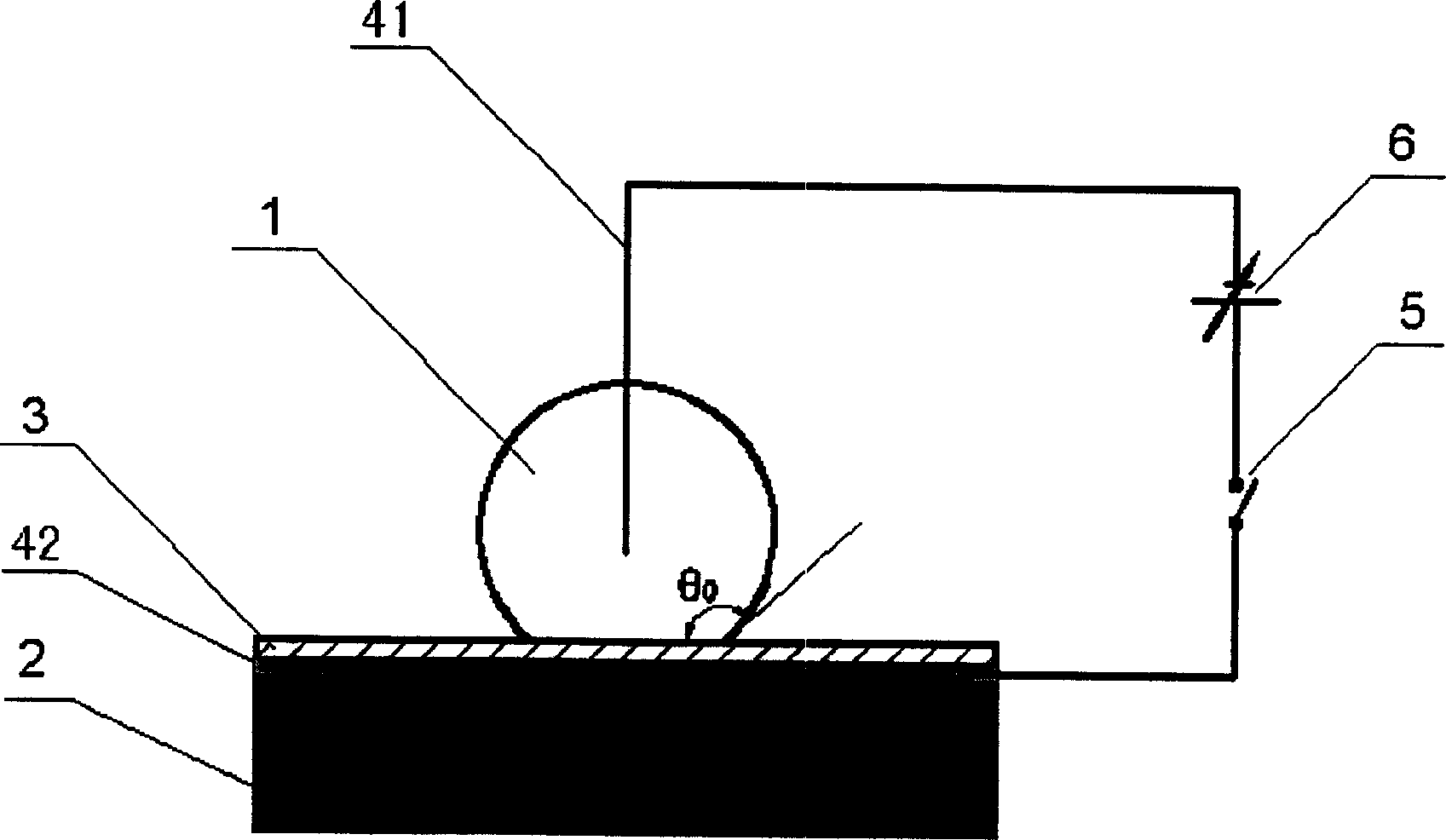

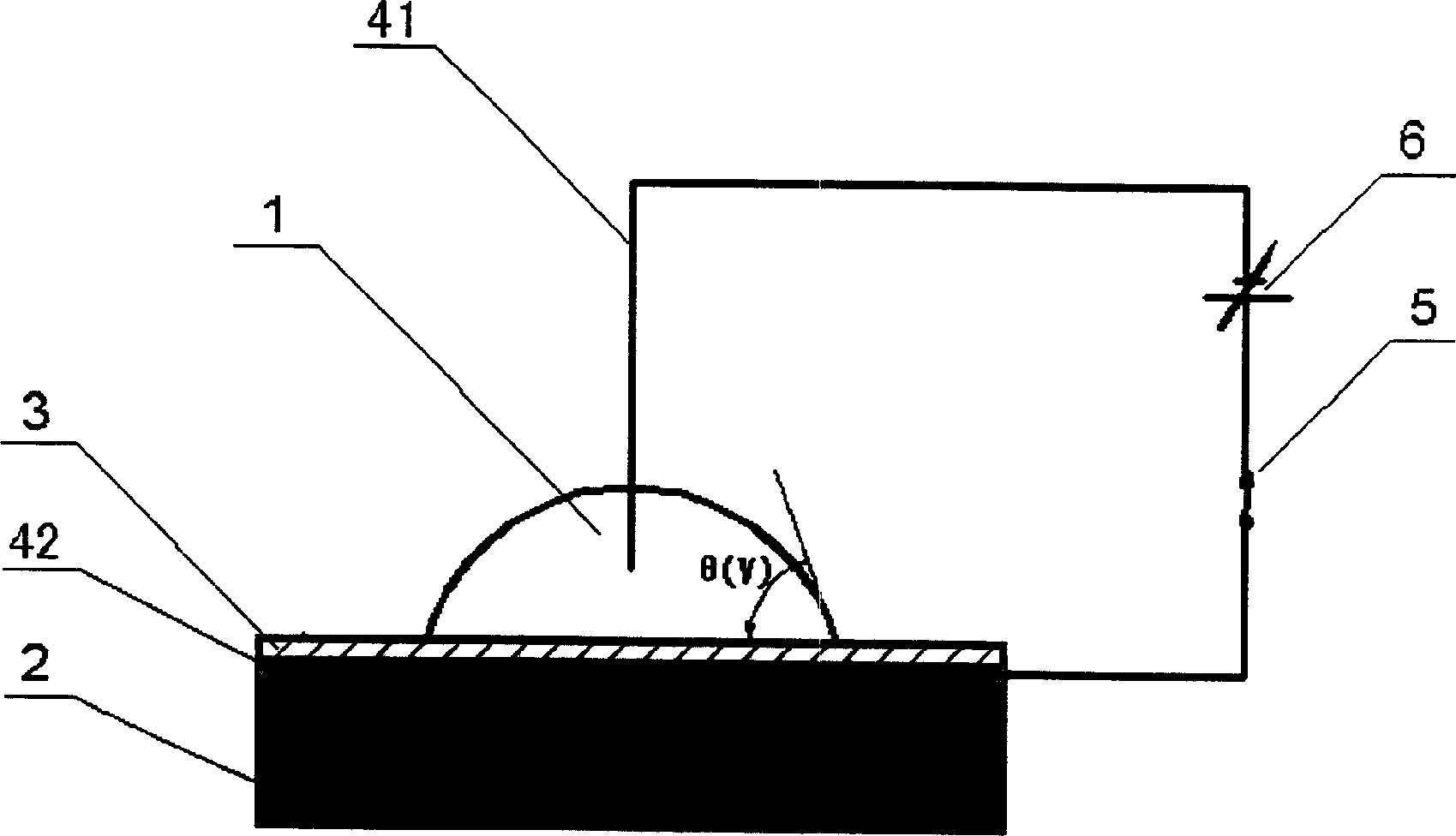

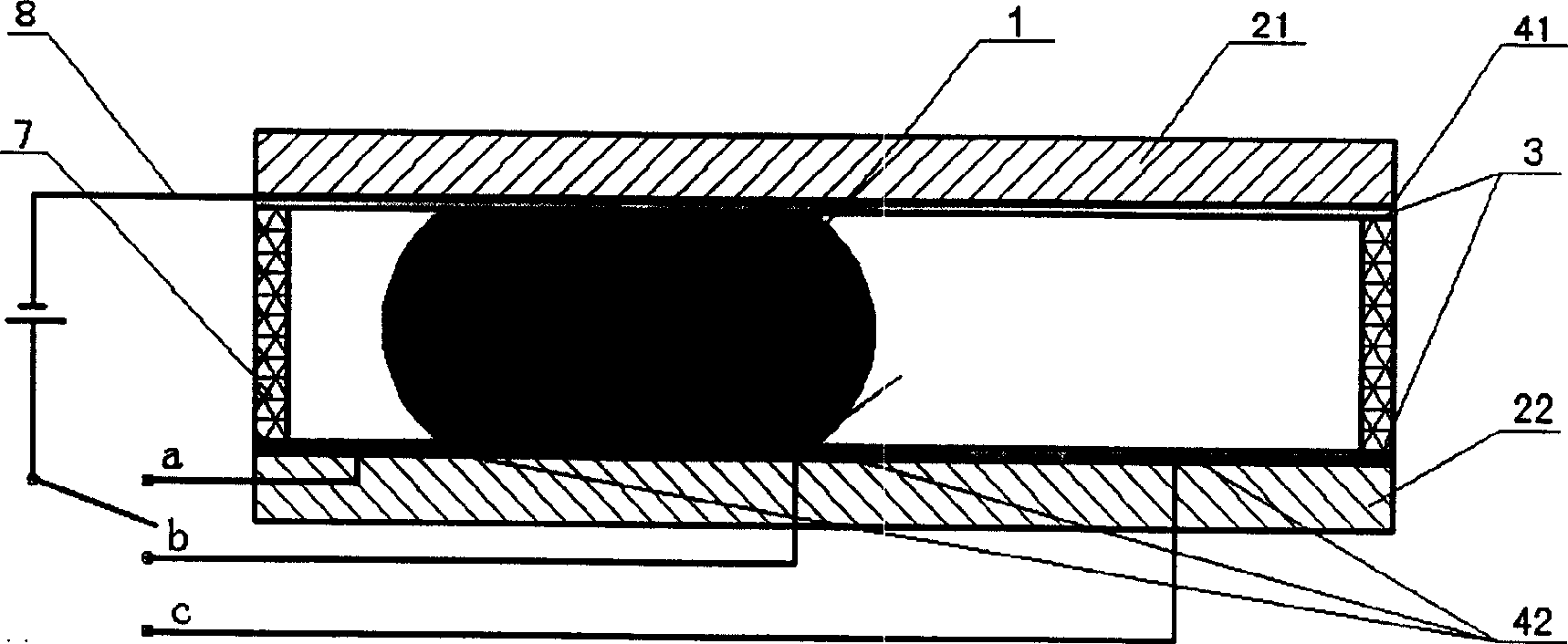

[0039] The structure of a kind of low-voltage droplet control device of the present invention is as follows: image 3 As shown, the device is composed of upper and lower layers of chips and corresponding control circuits. The lower chip is composed of the lower substrate 22 , the control electrode array 42 and the hydrophobic insulating layer 3 , and the upper chip is composed of the upper substrate 21 , the reference electrode layer 41 , the hydrophobic insulating layer 3 and the liquid inlet 9 . The upper and lower chips are mechanically connected by the support structure 7, the reference electrode layer 41 and the control electrode array 42 are electrically connected through the control circuit 8, the reference electrode layer 41 is grounded, and the control electrode array 42 is switched to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com