Leadless glass fit for machining energy-saving tube

A technology of lead-free glass and energy-saving lamps, applied in the field of lead-free glass, can solve the problems of increasing glass viscosity, high clarification, homogenization temperature, easy to produce streaks, etc., and achieve the effect of improving melting performance and improving physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

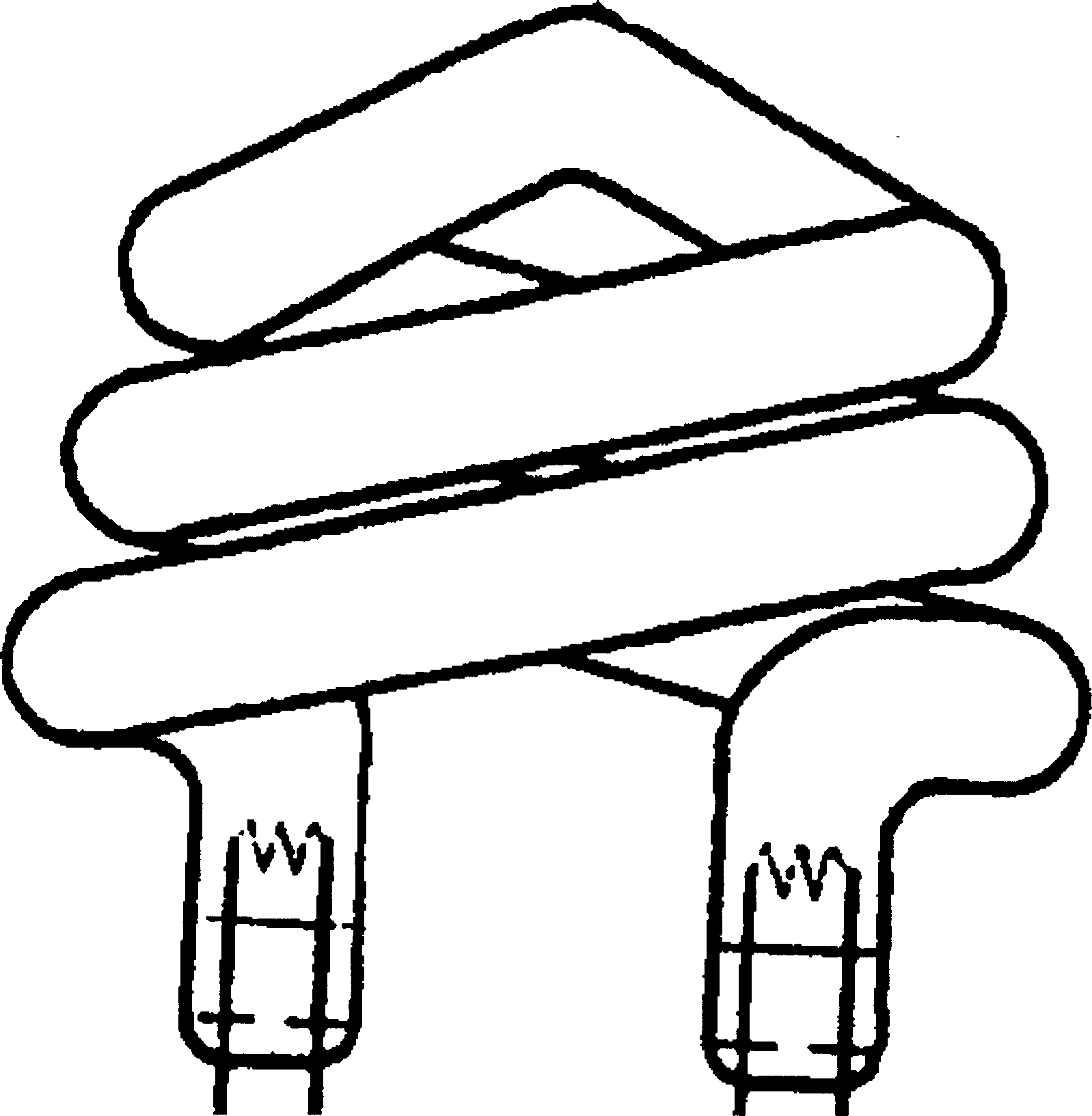

Image

Examples

Embodiment 1~2 and comparative example 1~6

[0020] The formula and main physical and chemical properties are shown in Table 1.

[0021] Among them: "Comparative Example 1" is a commonly used domestic lime glass, "Comparative Example 2" is a commonly used domestic light lead glass, "Comparative Example 3" is a Chinese patent 99118719.9, and "Comparative Example 4" is a Chinese patent 99102177.0. "Proportion 5" is Chinese patent 97115360.4, and "Comparative Example 6" is Chinese patent 93112860.9

[0022] In the glass components of Comparative Examples 3, 4, 5, and 6, the common point is that the divalent alkaline earth metals (CaO, MgO) are above 3.2%. As the content of alkaline earth metals increases, the softening temperature rises accordingly, and the glass frit The performance becomes shorter, which increases the difficulty of thermal processing operations, and increases the rejection rate of thermal processing procedures, which affects the production qualification rate of energy-saving lamp glass tubes to a certain exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com