Bulk granular material activating and integrating device for flyash brick

An integrated device and fly ash brick technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of large footprint of steam curing equipment, difficulty in steam curing activation, and unstable product quality and other problems, to achieve the effect of high operating cost, easy operation, and improvement of product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

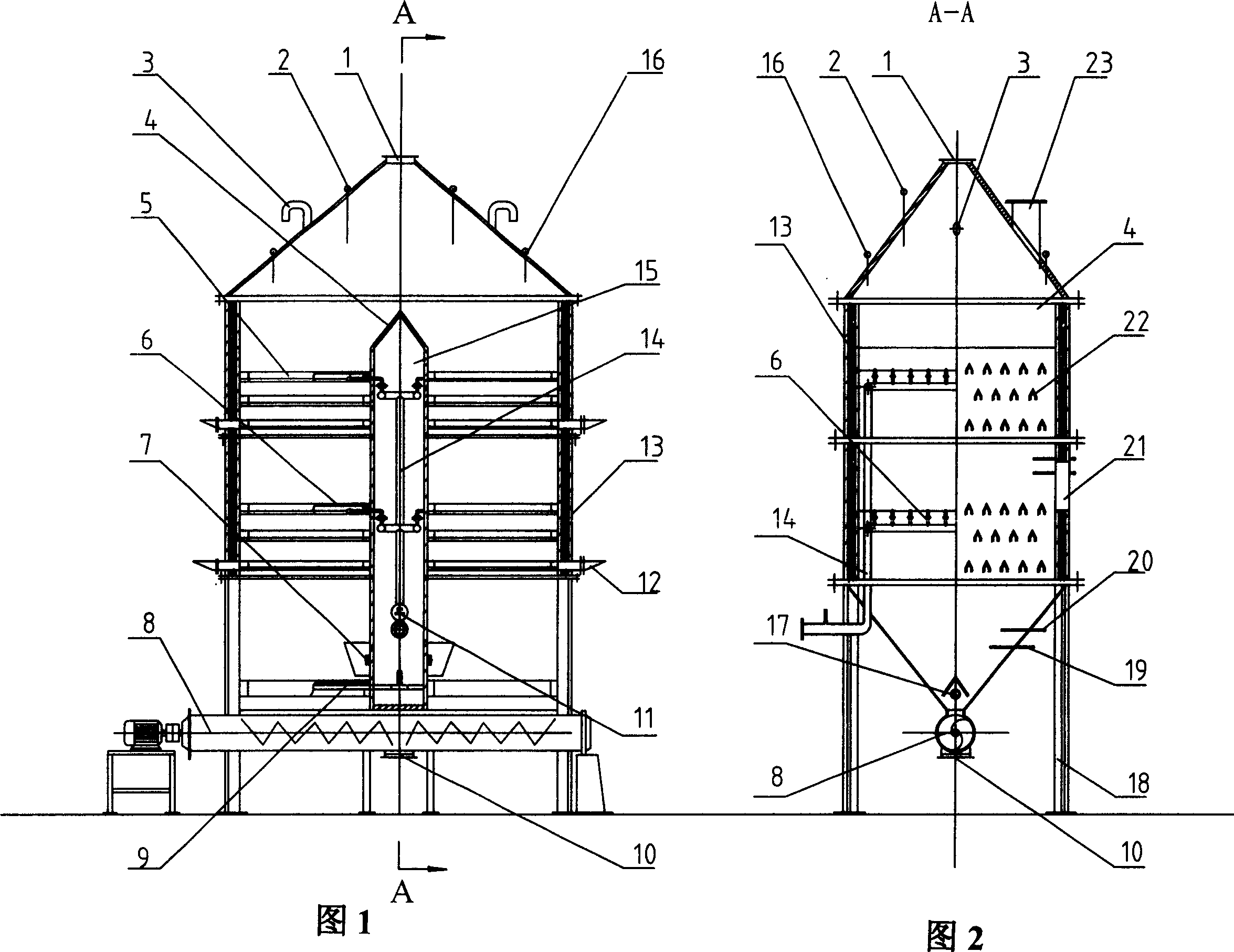

[0017] The specific structure and working process of the present invention will be described in detail according to Fig. 1-2. The device includes a machine body 13 with a feed port 1 and a discharge port 10, a support 18 thereof, and a control circuit. Among them, each control element and transmission signal in the control circuit are connected with the control circuit of the numerical control device of the molding equipment (patent applied for at the same time) according to the common circuit and the conventional control method. The body 13 is composed of multiple sections, and each section is connected into one body through flanges and fasteners. In order to improve its thermal efficiency, an insulation layer is set between the inner and outer cylinder walls of the body 13 . Its specifications and shapes can be determined according to actual use requirements.

[0018] The upper part of the body 13 is provided with a material preheating storage section, which uses a large v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com