Slewing ring

A technology for slewing rings and outer rings, applied in the field of slewing rings, can solve the problems of weakened characteristics, reduced lubricant pollution, and reduced ring life, etc., to achieve the effects of reduced risk of rupture, increased time delay, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

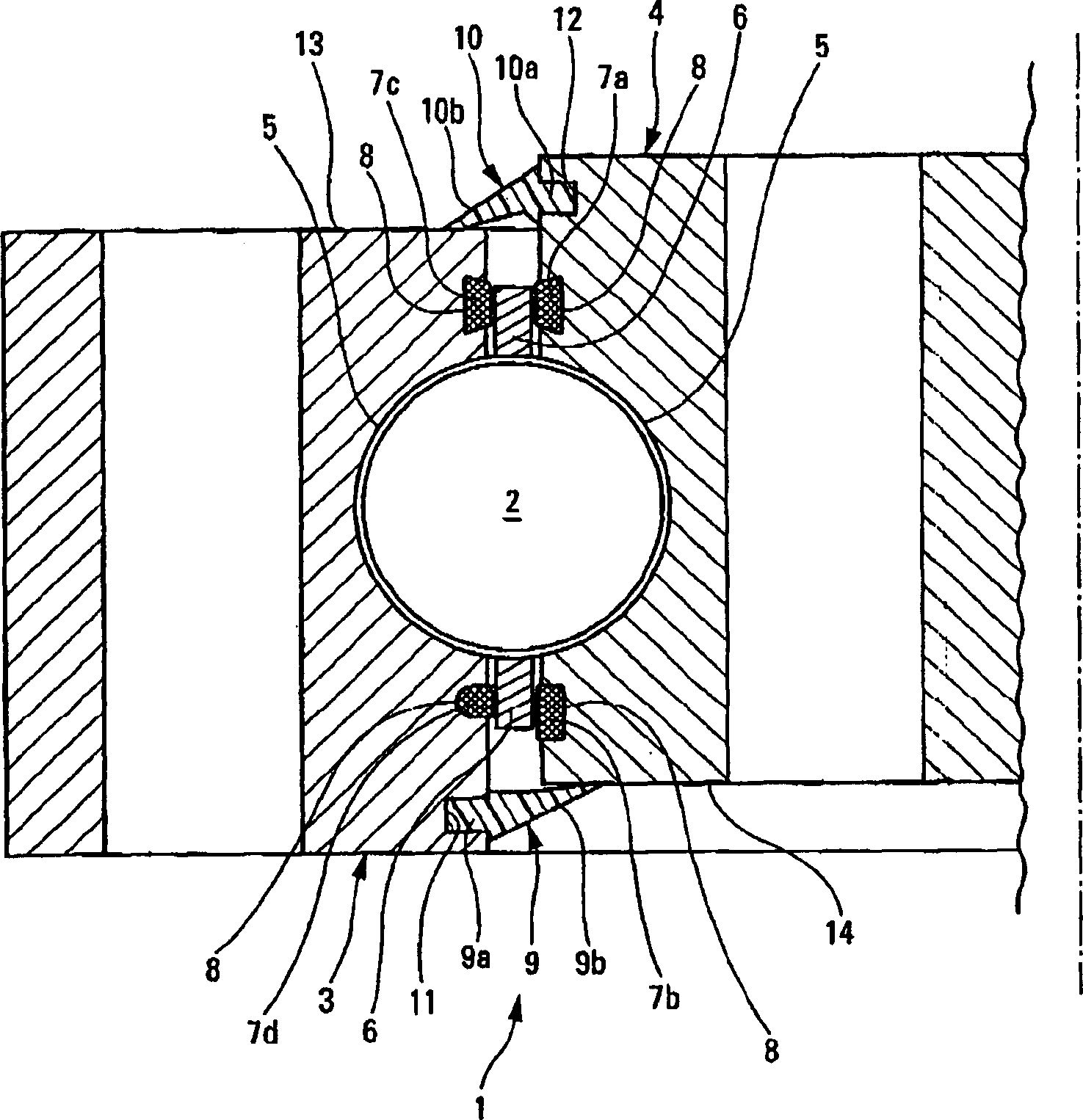

[0008] Further details and advantages of the invention emerge from the following detailed description of specific embodiments, which are non-limiting and illustrative, in conjunction with the accompanying drawings.

[0009] As shown in the figure, the slewing ring 1 comprises in a known manner:

[0010] Rolling member 2 (in this embodiment, ball member 2);

[0011] two concentric rings 3, 4 (one inner ring 3 and one outer ring 4) of steel, which rotate relative to each other, form the raceway 5 of the ball part 2, and

[0012] A steel cage 6 arranged between the two concentric rings 3, 4 extends in the axial direction of the slewing ring 1 on one side of the ball part 2, the cage rotates integrally with the ball part, and the The cage holds the rolling elements at regular intervals in the raceway.

[0013] Also, the slewing ring 1 comprises contact parts, also called contact rings 7a, 7b, 7c, 7d, made of a non-ferrous metal material, in this embodiment polyamide, for example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com